SATRONIC - Control boxes for oil burners

SATRONIC - Control boxes for oil burners

SATRONIC - Control boxes for oil burners

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

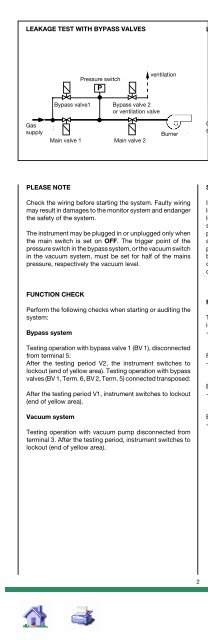

LEAKAGE TEST WITH BYPASS VALVES<br />

PLEASE NOTE<br />

Check the wiring be<strong>for</strong>e starting the system. Faulty wiring<br />

may result in damages to the monitor system and endanger<br />

the safety of the system.<br />

The instrument may be plugged in or unplugged only when<br />

the main switch is set on OFF. The trigger point of the<br />

pressure switch in the bypass system, or the vacuum switch<br />

in the vacuum system, must be set <strong>for</strong> half of the mains<br />

pressure, respectively the vacuum level.<br />

FUNCTION CHECK<br />

Per<strong>for</strong>m the following checks when starting or auditing the<br />

system:<br />

Bypass system<br />

Testing operation with bypass valve 1 (BV 1), disconnected<br />

from terminal 5:<br />

After the testing period V2, the instrument switches to<br />

lockout (end of yellow area). Testing operation with bypass<br />

valves (BV 1, Term. 6, BV 2, Term. 5) connected transposed:<br />

After the testing period V1, instrument switches to lockout<br />

(end of yellow area).<br />

Vacuum system<br />

Druckwächter<br />

Pressure switch<br />

P<br />

Bypass valve1 1 Bypass valve 2 oder 2<br />

Entlüftungsventil<br />

or ventilation valve<br />

Gas Gasnetz<br />

supply<br />

Hauptventil Main valve 1 1 Hauptventil Main valve 2 2<br />

ventilation (Entlüftung)<br />

Burner Brenner<br />

Testing operation with vacuum pump disconnected from<br />

terminal 3. After the testing period, instrument switches to<br />

lockout (end of yellow area).<br />

2<br />

LEAKAGE TEST WITH VACUUM PUMP<br />

Gasnetz<br />

SAFETY AND SWITCH FUNCTIONS<br />

If the pressure or the vacuum switch contact is stuck, a<br />

lockout will be the result in any case. In both systems,<br />

leakage of the auxiliary valves is also checked. A burner<br />

start-up without a preceding leakage test concluded<br />

positively is impossible. The blower motor of the burner is<br />

switched from the MDP. If <strong>for</strong> any reason the leakage<br />

programme does not start-up in a normal shut-down, the<br />

blower motor does not turn off. For the next normal switchon,<br />

there is no burner start-up since the air proving switch<br />

contact remains in its operating position.<br />

FAULT FINDING<br />

Vakuumpumpe<br />

Vacuum<br />

pump<br />

VacuumVakuumswitchwächter P<br />

(Entlüftung)<br />

ventilation<br />

ventilation Entlüftungsventil<br />

valve (spannungslos offen)<br />

Gas<br />

supply<br />

Burner Brenner<br />

Main Hauptventil valve 1 1 Hauptventil Main valve 22<br />

Testing programme does not operate, programme remains<br />

in the white area:<br />

-> No phase on terminal 9, automatic burner assembly on<br />

lockout.<br />

Programme sequence stops in the black area:<br />

-> Connection terminal 17 to terminal 18 (bypass) or terminal<br />

18 to terminal 19 (vacuum) is missing.<br />

Blower motor does not start:<br />

-> No feedback from the automatic burner assembly on<br />

terminal 4.<br />

Blower motor does not turn off:<br />

-> Permanent phase on terminal 4, programme switching<br />

system defective.<br />

MDP 720-1