Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

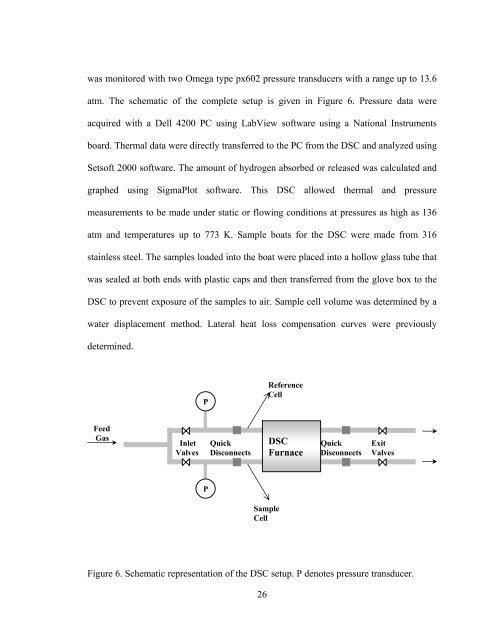

was monitored with two Omega type px602 pressure transducers with a range up to 13.6<br />

atm. The schematic of the complete setup is given in Figure 6. Pressure data were<br />

acquired with a Dell 4200 PC using LabView software using a National Instruments<br />

board. Thermal data were directly transferred to the PC from the DSC and analyzed using<br />

Setsoft 2000 software. The amount of hydrogen absorbed or released was calculated and<br />

graphed using SigmaPlot software. This DSC allowed thermal and pressure<br />

measurements to be made under static or flowing conditions at pressures as high as 136<br />

atm and temperatures up to 773 K. Sample boats for the DSC were made from 316<br />

stainless steel. The samples loaded into the boat were placed into a hollow glass tube that<br />

was sealed at both ends with plastic caps and then transferred from the glove box to the<br />

DSC to prevent exposure of the samples to air. Sample cell volume was determined by a<br />

water displacement method. Lateral heat loss compensation curves were previously<br />

determined.<br />

P<br />

Reference<br />

Cell<br />

Feed<br />

Gas<br />

Inlet<br />

Valves<br />

Quick<br />

Disconnects<br />

DSC<br />

Furnace<br />

Quick<br />

Disconnects<br />

Exit<br />

Valves<br />

P<br />

Sample<br />

Cell<br />

Figure 6. Schematic representation of the DSC setup. P denotes pressure transducer.<br />

26