Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

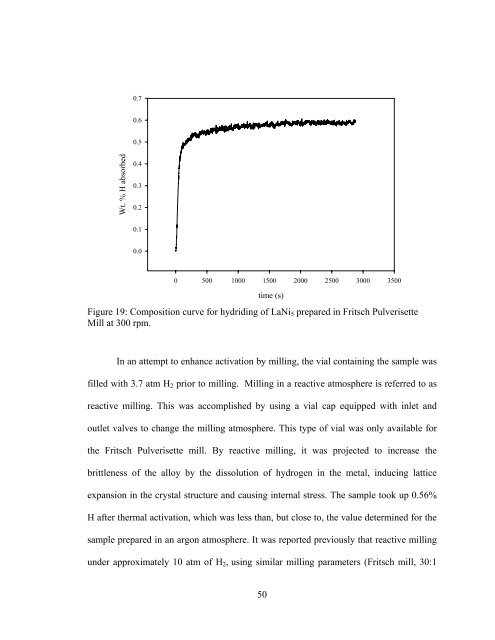

0.7<br />

0.6<br />

0.5<br />

Wt. % H absorbed<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

0 500 1000 1500 2000 2500 3000 3500<br />

time (s)<br />

Figure 19: Composition curve for hydriding of LaNi 5 prepared in Fritsch Pulverisette<br />

Mill at 300 rpm.<br />

In an attempt to enhance activation by milling, the vial containing the sample was<br />

filled with 3.7 atm H 2 prior to milling. Milling in a reactive atmosphere is referred to as<br />

reactive milling. This was accomplished by using a vial cap equipped with inlet and<br />

outlet valves to change the milling atmosphere. This type of vial was only available for<br />

the Fritsch Pulverisette mill. By reactive milling, it was projected to increase the<br />

brittleness of the alloy by the dissolution of hydrogen in the metal, inducing lattice<br />

expansion in the crystal structure and causing internal stress. The sample took up 0.56%<br />

H after thermal activation, which was less than, but close to, the value determined for the<br />

sample prepared in an argon atmosphere. It was reported previously that reactive milling<br />

under approximately 10 atm of H 2 , using similar milling parameters (Fritsch mill, 30:1<br />

50