You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

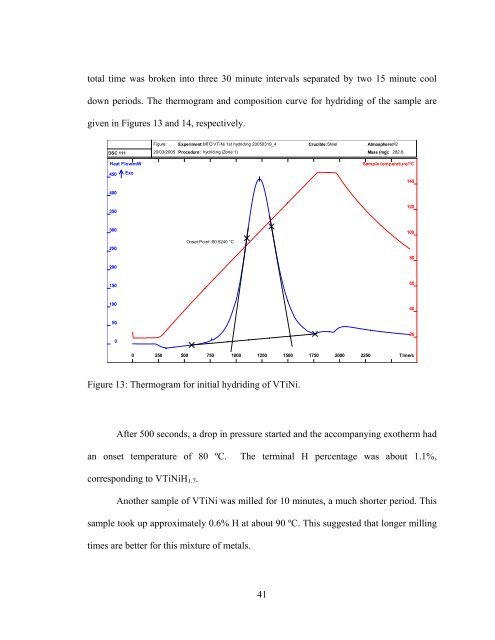

total time was broken into three 30 minute intervals separated by two 15 minute cool<br />

down periods. The thermogram and composition curve for hydriding of the sample are<br />

given in Figures 13 and 14, respectively.<br />

DSC 111<br />

Heat Flow/mW<br />

450 Exo<br />

Figure: Experiment:MTO VTiNi 1st hydriding 20050319_4<br />

Crucible:Steel<br />

Atmosphere:H2<br />

20/03/2005 Procedure: hydriding (Zone 1)<br />

Mass (mg): 282.6<br />

Sample temperature/°C<br />

140<br />

400<br />

350<br />

120<br />

300<br />

250<br />

200<br />

Onset Point :80.5240 °C<br />

100<br />

80<br />

150<br />

60<br />

100<br />

40<br />

50<br />

0<br />

20<br />

0 250 500 750 1000 1250 1500 1750 2000 2250<br />

Time/s<br />

Figure 13: Thermogram for initial hydriding of VTiNi.<br />

After 500 seconds, a drop in pressure started and the accompanying exotherm had<br />

an onset temperature of 80 ºC. The terminal H percentage was about 1.1%,<br />

corresponding to VTiNiH 1.7 .<br />

Another sample of VTiNi was milled for 10 minutes, a much shorter period. This<br />

sample took up approximately 0.6% H at about 90 ºC. This suggested that longer milling<br />

times are better for this mixture of metals.<br />

41