WINTER 2017

Distributor's Link Magazine Winter Issue 2017 / Vol 40 No1

Distributor's Link Magazine Winter Issue 2017 / Vol 40 No1

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

138<br />

THE DISTRIBUTOR’S LINK<br />

DURAFORCE THE FASTENER INDUSTRY’S MOST REVOLUTIONARY TECHNOLOGICAL IMPROVEMENT FOR 85 YEARS from page 44<br />

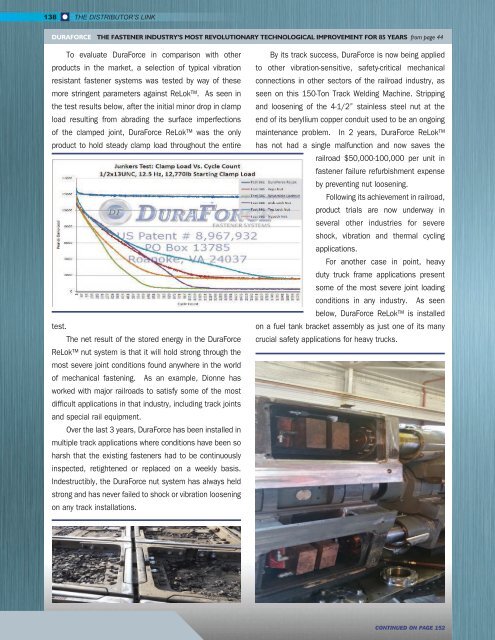

To evaluate DuraForce in comparison with other<br />

products in the market, a selection of typical vibration<br />

resistant fastener systems was tested by way of these<br />

more stringent parameters against ReLok. As seen in<br />

the test results below, after the initial minor drop in clamp<br />

load resulting from abrading the surface imperfections<br />

of the clamped joint, DuraForce ReLok was the only<br />

product to hold steady clamp load throughout the entire<br />

test.<br />

The net result of the stored energy in the DuraForce<br />

ReLok nut system is that it will hold strong through the<br />

most severe joint conditions found anywhere in the world<br />

of mechanical fastening. As an example, Dionne has<br />

worked with major railroads to satisfy some of the most<br />

difficult applications in that industry, including track joints<br />

and special rail equipment.<br />

Over the last 3 years, DuraForce has been installed in<br />

multiple track applications where conditions have been so<br />

harsh that the existing fasteners had to be continuously<br />

inspected, retightened or replaced on a weekly basis.<br />

Indestructibly, the DuraForce nut system has always held<br />

strong and has never failed to shock or vibration loosening<br />

on any track installations.<br />

By its track success, DuraForce is now being applied<br />

to other vibration-sensitive, safety-critical mechanical<br />

connections in other sectors of the railroad industry, as<br />

seen on this 150-Ton Track Welding Machine. Stripping<br />

and loosening of the 4-1/2” stainless steel nut at the<br />

end of its beryllium copper conduit used to be an ongoing<br />

maintenance problem. In 2 years, DuraForce ReLok<br />

has not had a single malfunction and now saves the<br />

railroad $50,000-100,000 per unit in<br />

fastener failure refurbishment expense<br />

by preventing nut loosening.<br />

Following its achievement in railroad,<br />

product trials are now underway in<br />

several other industries for severe<br />

shock, vibration and thermal cycling<br />

applications.<br />

For another case in point, heavy<br />

duty truck frame applications present<br />

some of the most severe joint loading<br />

conditions in any industry. As seen<br />

below, DuraForce ReLok is installed<br />

on a fuel tank bracket assembly as just one of its many<br />

crucial safety applications for heavy trucks.<br />

CONTINUED ON PAGE 152