WINTER 2017

Distributor's Link Magazine Winter Issue 2017 / Vol 40 No1

Distributor's Link Magazine Winter Issue 2017 / Vol 40 No1

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

94<br />

THE DISTRIBUTOR’S LINK<br />

BENGT BLENDULF A LOGICAL APPROACH TO A BOLTED JOINT DESIGN from page 8<br />

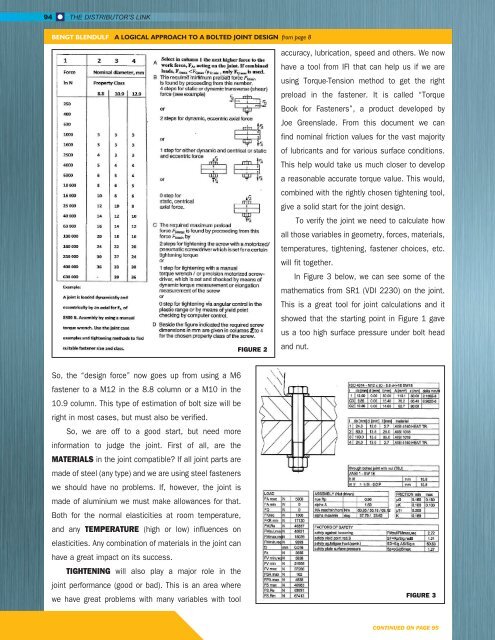

FIGURE 2<br />

accuracy, lubrication, speed and others. We now<br />

have a tool from IFI that can help us if we are<br />

using Torque-Tension method to get the right<br />

preload in the fastener. It is called “Torque<br />

Book for Fasteners”, a product developed by<br />

Joe Greenslade. From this document we can<br />

find nominal friction values for the vast majority<br />

of lubricants and for various surface conditions.<br />

This help would take us much closer to develop<br />

a reasonable accurate torque value. This would,<br />

combined with the rightly chosen tightening tool,<br />

give a solid start for the joint design.<br />

To verify the joint we need to calculate how<br />

all those variables in geometry, forces, materials,<br />

temperatures, tightening, fastener choices, etc.<br />

will fit together.<br />

In Figure 3 below, we can see some of the<br />

mathematics from SR1 (VDI 2230) on the joint.<br />

This is a great tool for joint calculations and it<br />

showed that the starting point in Figure 1 gave<br />

us a too high surface pressure under bolt head<br />

and nut.<br />

So, the “design force” now goes up from using a M6<br />

fastener to a M12 in the 8.8 column or a M10 in the<br />

10.9 column. This type of estimation of bolt size will be<br />

right in most cases, but must also be verified.<br />

So, we are off to a good start, but need more<br />

information to judge the joint. First of all, are the<br />

MATERIALS in the joint compatible? If all joint parts are<br />

made of steel (any type) and we are using steel fasteners<br />

we should have no problems. If, however, the joint is<br />

made of aluminium we must make allowances for that.<br />

Both for the normal elasticities at room temperature,<br />

and any TEMPERATURE (high or low) influences on<br />

elasticities. Any combination of materials in the joint can<br />

have a great impact on its success.<br />

TIGHTENING will also play a major role in the<br />

joint performance (good or bad). This is an area where<br />

we have great problems with many variables with tool<br />

FIGURE 3<br />

CONTINUED ON PAGE 95