WINTER 2017

Distributor's Link Magazine Winter Issue 2017 / Vol 40 No1

Distributor's Link Magazine Winter Issue 2017 / Vol 40 No1

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

74<br />

THE DISTRIBUTOR’S LINK<br />

APEX SUPPLY CHAIN TECHNOLOGIES<br />

4393 Digital Way, Mason, Ohio 45040 USA<br />

TEL 1-800-229-7912 EMAIL info@apexsupplychain.com WEB www.apexsupplychain.com<br />

ACTYLUS SMART BIN SYSTEM NOW AVAILABLE IN<br />

ONE AND TWO SHELF MODELS FOR BENCHTOP USE<br />

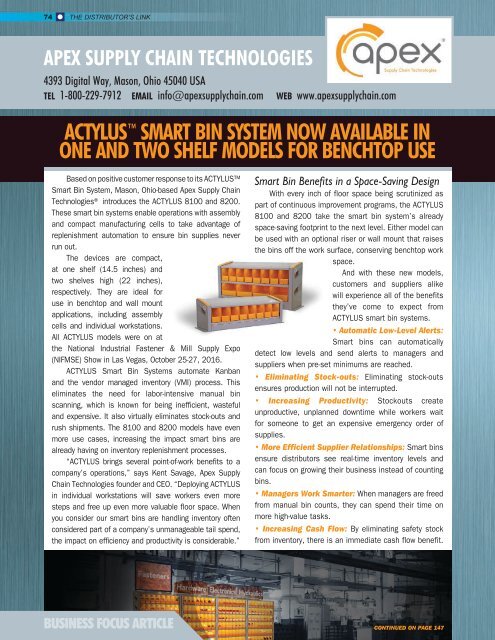

Based on positive customer response to its ACTYLUS<br />

Smart Bin System, Mason, Ohio-based Apex Supply Chain<br />

Technologies® introduces the ACTYLUS 8100 and 8200.<br />

These smart bin systems enable operations with assembly<br />

and compact manufacturing cells to take advantage of<br />

replenishment automation to ensure bin supplies never<br />

run out.<br />

The devices are compact,<br />

at one shelf (14.5 inches) and<br />

two shelves high (22 inches),<br />

respectively. They are ideal for<br />

use in benchtop and wall mount<br />

applications, including assembly<br />

cells and individual workstations.<br />

All ACTYLUS models were on at<br />

the National Industrial Fastener & Mill Supply Expo<br />

(NIFMSE) Show in Las Vegas, October 25-27, 2016.<br />

ACTYLUS Smart Bin Systems automate Kanban<br />

and the vendor managed inventory (VMI) process. This<br />

eliminates the need for labor-intensive manual bin<br />

scanning, which is known for being inefficient, wasteful<br />

and expensive. It also virtually eliminates stock-outs and<br />

rush shipments. The 8100 and 8200 models have even<br />

more use cases, increasing the impact smart bins are<br />

already having on inventory replenishment processes.<br />

“ACTYLUS brings several point-of-work benefits to a<br />

company’s operations,” says Kent Savage, Apex Supply<br />

Chain Technologies founder and CEO. “Deploying ACTYLUS<br />

in individual workstations will save workers even more<br />

steps and free up even more valuable floor space. When<br />

you consider our smart bins are handling inventory often<br />

considered part of a company’s unmanageable tail spend,<br />

the impact on efficiency and productivity is considerable.”<br />

Smart Bin Benefits in a Space-Saving Design<br />

With every inch of floor space being scrutinized as<br />

part of continuous improvement programs, the ACTYLUS<br />

8100 and 8200 take the smart bin system’s already<br />

space-saving footprint to the next level. Either model can<br />

be used with an optional riser or wall mount that raises<br />

the bins off the work surface, conserving benchtop work<br />

space.<br />

And with these new models,<br />

customers and suppliers alike<br />

will experience all of the benefits<br />

they’ve come to expect from<br />

ACTYLUS smart bin systems.<br />

• Automatic Low-Level Alerts:<br />

Smart bins can automatically<br />

detect low levels and send alerts to managers and<br />

suppliers when pre-set minimums are reached.<br />

• Eliminating Stock-outs: Eliminating stock-outs<br />

ensures production will not be interrupted.<br />

• Increasing Productivity: Stockouts create<br />

unproductive, unplanned downtime while workers wait<br />

for someone to get an expensive emergency order of<br />

supplies.<br />

• More Efficient Supplier Relationships: Smart bins<br />

ensure distributors see real-time inventory levels and<br />

can focus on growing their business instead of counting<br />

bins.<br />

• Managers Work Smarter: When managers are freed<br />

from manual bin counts, they can spend their time on<br />

more high-value tasks.<br />

• Increasing Cash Flow: By eliminating safety stock<br />

from inventory, there is an immediate cash flow benefit.<br />

BUSINESS FOCUS ARTICLE<br />

CONTINUED ON PAGE 147