CU1703

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CASEstudy<br />

Right in the frame<br />

Pinewood Structures drives quality with Elecosoft Framing<br />

Pinewood Structures has been<br />

operating at the heart of the<br />

growing UK timber frame<br />

manufacturing market since 1981. It<br />

has experienced ongoing<br />

transformation which has already seen<br />

it grow significantly, embrace<br />

automation and digitise many<br />

traditional processes.<br />

Its use of software has been a<br />

fundamental part of this change.<br />

Framing software from Elecosoft has<br />

played an increasing role in helping the<br />

company achieve the quality production<br />

for which the company is renowned.<br />

Nick Worboys is Quality Manager at<br />

Pinewood. He outlined his role as "To<br />

make us the best we can possibly be,<br />

and link all processes and systems<br />

together," something he believes is<br />

underpinned by software. He has been<br />

involved throughout the company's<br />

digitisation of its scheduling process: "It<br />

was a journey that began by our<br />

developing a piece of software to cut<br />

panels for us, but then we realised<br />

there were other systems that could do<br />

that, and possibly more. We found<br />

Framing, and have worked with<br />

Elecosoft to help evolve the software<br />

over time, to the point we are at today.<br />

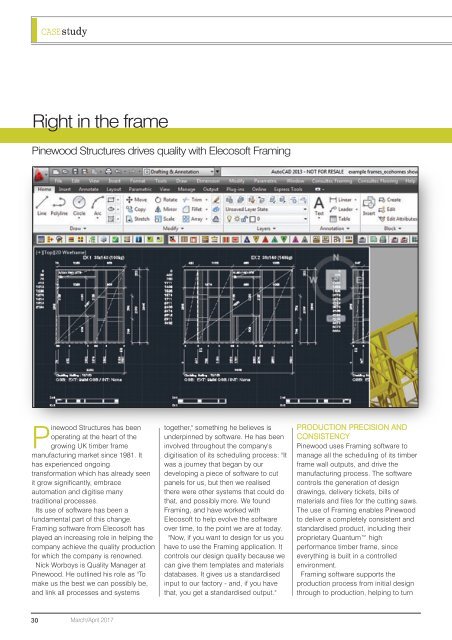

"Now, if you want to design for us you<br />

have to use the Framing application. It<br />

controls our design quality because we<br />

can give them templates and materials<br />

databases. It gives us a standardised<br />

input to our factory - and, if you have<br />

that, you get a standardised output."<br />

PRODUCTION PRECISION AND<br />

CONSISTENCY<br />

Pinewood uses Framing software to<br />

manage all the scheduling of its timber<br />

frame wall outputs, and drive the<br />

manufacturing process. The software<br />

controls the generation of design<br />

drawings, delivery tickets, bills of<br />

materials and files for the cutting saws.<br />

The use of Framing enables Pinewood<br />

to deliver a completely consistent and<br />

standardised product, including their<br />

proprietary Quantum high<br />

performance timber frame, since<br />

everything is built in a controlled<br />

environment.<br />

Framing software supports the<br />

production process from initial design<br />

through to production, helping to turn<br />

30<br />

March/April 2017