T-Series Climate Changer ® Air Handlers Sizes 3 through ... - Trane

T-Series Climate Changer ® Air Handlers Sizes 3 through ... - Trane

T-Series Climate Changer ® Air Handlers Sizes 3 through ... - Trane

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

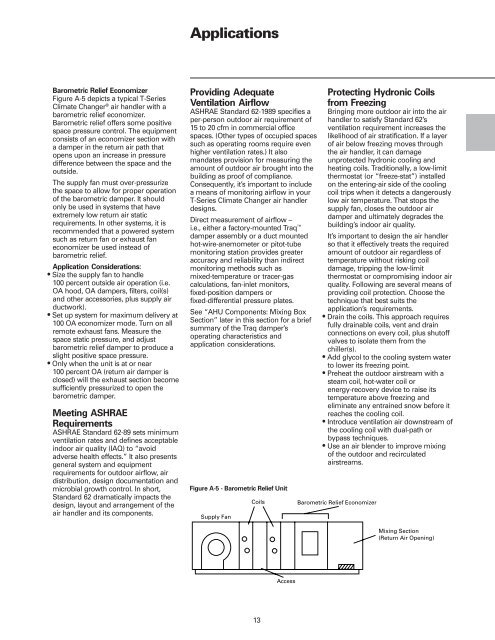

Barometric Relief Economizer<br />

Figure A-5 depicts a typical T-<strong>Series</strong><br />

<strong>Climate</strong> <strong>Changer</strong> <strong>®</strong> air handler with a<br />

barometric relief economizer.<br />

Barometric relief offers some positive<br />

space pressure control. The equipment<br />

consists of an economizer section with<br />

a damper in the return air path that<br />

opens upon an increase in pressure<br />

difference between the space and the<br />

outside.<br />

The supply fan must over-pressurize<br />

the space to allow for proper operation<br />

of the barometric damper. It should<br />

only be used in systems that have<br />

extremely low return air static<br />

requirements. In other systems, it is<br />

recommended that a powered system<br />

such as return fan or exhaust fan<br />

economizer be used instead of<br />

barometric relief.<br />

Application Considerations:<br />

• Size the supply fan to handle<br />

100 percent outside air operation (i.e.<br />

OA hood, OA dampers, filters, coil(s)<br />

and other accessories, plus supply air<br />

ductwork).<br />

• Set up system for maximum delivery at<br />

100 OA economizer mode. Turn on all<br />

remote exhaust fans. Measure the<br />

space static pressure, and adjust<br />

barometric relief damper to produce a<br />

slight positive space pressure.<br />

• Only when the unit is at or near<br />

100 percent OA (return air damper is<br />

closed) will the exhaust section become<br />

sufficiently pressurized to open the<br />

barometric damper.<br />

Meeting ASHRAE<br />

Requirements<br />

ASHRAE Standard 62-89 sets minimum<br />

ventilation rates and defines acceptable<br />

indoor air quality (IAQ) to “avoid<br />

adverse health effects.” It also presents<br />

general system and equipment<br />

requirements for outdoor airflow, air<br />

distribution, design documentation and<br />

microbial growth control. In short,<br />

Standard 62 dramatically impacts the<br />

design, layout and arrangement of the<br />

air handler and its components.<br />

Applications<br />

Providing Adequate<br />

Ventilation <strong>Air</strong>flow<br />

ASHRAE Standard 62-1989 specifies a<br />

per-person outdoor air requirement of<br />

15 to 20 cfm in commercial office<br />

spaces. (Other types of occupied spaces<br />

such as operating rooms require even<br />

higher ventilation rates.) It also<br />

mandates provision for measuring the<br />

amount of outdoor air brought into the<br />

building as proof of compliance.<br />

Consequently, it’s important to include<br />

a means of monitoring airflow in your<br />

T-<strong>Series</strong> <strong>Climate</strong> <strong>Changer</strong> air handler<br />

designs.<br />

Direct measurement of airflow –<br />

i.e., either a factory-mounted Traq damper assembly or a duct mounted<br />

hot-wire-anemometer or pitot-tube<br />

monitoring station provides greater<br />

accuracy and reliability than indirect<br />

monitoring methods such as<br />

mixed-temperature or tracer-gas<br />

calculations, fan-inlet monitors,<br />

fixed-position dampers or<br />

fixed-differential pressure plates.<br />

See “AHU Components: Mixing Box<br />

Section” later in this section for a brief<br />

summary of the Traq damper’s<br />

operating characteristics and<br />

application considerations.<br />

Figure A-5 - Barometric Relief Unit<br />

13<br />

Protecting Hydronic Coils<br />

from Freezing<br />

Bringing more outdoor air into the air<br />

handler to satisfy Standard 62’s<br />

ventilation requirement increases the<br />

likelihood of air stratification. If a layer<br />

of air below freezing moves <strong>through</strong><br />

the air handler, it can damage<br />

unprotected hydronic cooling and<br />

heating coils. Traditionally, a low-limit<br />

thermostat (or “freeze-stat”) installed<br />

on the entering-air side of the cooling<br />

coil trips when it detects a dangerously<br />

low air temperature. That stops the<br />

supply fan, closes the outdoor air<br />

damper and ultimately degrades the<br />

building’s indoor air quality.<br />

It’s important to design the air handler<br />

so that it effectively treats the required<br />

amount of outdoor air regardless of<br />

temperature without risking coil<br />

damage, tripping the low-limit<br />

thermostat or compromising indoor air<br />

quality. Following are several means of<br />

providing coil protection. Choose the<br />

technique that best suits the<br />

application’s requirements.<br />

• Drain the coils. This approach requires<br />

fully drainable coils, vent and drain<br />

connections on every coil, plus shutoff<br />

valves to isolate them from the<br />

chiller(s).<br />

• Add glycol to the cooling system water<br />

to lower its freezing point.<br />

• Preheat the outdoor airstream with a<br />

steam coil, hot-water coil or<br />

energy-recovery device to raise its<br />

temperature above freezing and<br />

eliminate any entrained snow before it<br />

reaches the cooling coil.<br />

• Introduce ventilation air downstream of<br />

the cooling coil with dual-path or<br />

bypass techniques.<br />

• Use an air blender to improve mixing<br />

of the outdoor and recirculated<br />

airstreams.