Smart Industry 1/2018

Smart Industry 1/2018 - The IoT Business Magazine - powered by Avnet Silica

Smart Industry 1/2018 - The IoT Business Magazine - powered by Avnet Silica

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

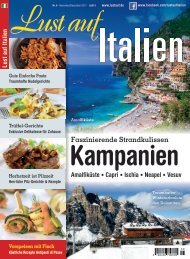

Business process control with smartphone or tablet (Komsa)<br />

IDS in practice<br />

■ How to create a really smart factory<br />

Steel producer Thyssenkrupp Steel Europe has provided the first use case for<br />

IDS with an information system for truck logistics. The aim is to optimize the<br />

loading and unloading times of trucks and adapt them flexibly according to<br />

transport routes and traffic disruptions. The company handles around 20,000<br />

trucks per month so, with just 30 minutes available to load and unload each<br />

truck, any delay in arrival can quickly throw the entire schedule into disarray.<br />

Technology partner Komsa and Thyssenkrupp have developed an end-to-end<br />

combination of connected devices between the truck drivers and the weigh<br />

gates at the entrance to the loading bays. The aim is to automate rescheduling<br />

of truck arrivals based on reliable online data, by using real-time management<br />

of time slots and dynamically estimated arrival times Messaging using GS1 EDI<br />

XML allows instant and comprehensive status change notification.<br />

IDS supports interaction between humans and machines (Festo)<br />

Control and automation firm Festo and bearings maker Schaeffler have<br />

developed an integrated equipment platform using Object Linking and Embedding<br />

(OLE) for process control unified architecture (OPC-UA) over an IDS secure<br />

channel. The modular service-based concept can be extended to incorporate<br />

semantic technologies or other protocols and provides support for horizontal<br />

integration across value chains. System features include process optimization<br />

based on higher transparency, knowledge creation and documentation based on<br />

data correlation and analytics, and the transfer of new added value to partners.<br />

Salzgitter, a German steel producer, with engineering and electronics company<br />

Bosch have developed an intelligent stock information system called From Ore to<br />

Refrigerator. It merges existing procurement systems to analyze the underlying<br />

supply chain and reveal possibilities of new business models for brokerage of<br />

raw materials and metals to customers. Results: automatic management of<br />

semantic description of steel quality criteria, machine interface for availability,<br />

and greater transparency and faster response times.<br />

vitally important for adoption. The<br />

requirements range from simple access<br />

rights and identity management to<br />

affordable costs. Last but not least,<br />

quality counts. Quality of service must<br />

be ensured and governed by service<br />

level agreements across the IoT and<br />

business networks.<br />

How many instances of IoT platforms<br />

would a company need?<br />

The abundance of IoT platforms with<br />

each vendor of machinery having its<br />

own [architecture] leads to situations<br />

where one factory may have to deal<br />

with several IoT platforms. The producer<br />

doesn’t want this. As the data<br />

owner, the producer wants control<br />

over his own data instead of feeding<br />

his production data into IoT platforms<br />

of vendors. As much as the producer<br />

wants the big picture in real time, he<br />

doesn’t want to engage in complex<br />

integrating projects that connect the<br />

IoT platforms. Therefore, networked<br />

communication is needed that connects<br />

whole ecosystems (supply/<br />

demand/production networks). One<br />

single account from the provider of<br />

choice will give global access across<br />

IoT or <strong>Industry</strong> 4.0 platforms. With<br />

Regispace (www.regispace.net), we've<br />

successfully implemented core IDS<br />

proposals in a number of industries.<br />

Can you give us a few examples?<br />

Several partners in Luxembourg and the<br />

UK operate Regify platforms for the<br />

health sector. These platforms ensure<br />

full control of data for the data owner,<br />

compliance regarding data privacy and<br />

Unlike the<br />

Internet,<br />

which has a<br />

sophisticated<br />

governance<br />

ecosystem,<br />

the whole<br />

world of<br />

blockchain<br />

is the Wild<br />

West<br />

Kurt Kammerer<br />

CEO of Regify and<br />

founder of Regify Asia<br />

security, and at the same time they<br />

enable networked communication<br />

across the entire health sector.<br />

Regify’s patented and distributed<br />

architecture connects users (from<br />

humans to machines) across instances<br />

of platforms, lets them transact while<br />

respecting access rights that each<br />

owner of data can grant or revoke at<br />

a granular level. Users simply register<br />

with their chosen provider to gain full<br />

access to other users across the data<br />

space providers.<br />

How about standards for secure<br />

data space?<br />

Standardization efforts such as IDS<br />

and other international approaches<br />

are important because they facilitate<br />

cooperation within an industry. To<br />

date, many users consider comprehensive<br />

architecture and data models<br />

as too theoretical for today’s challenges.<br />

Therefore, Regify solutions<br />

work on every digital channel and<br />

every device independently of which<br />

data partners want to exchange,<br />

standardized or unstandardized. Our<br />

European, and especially our Asian,<br />

customers are calling for this.<br />

83