Smart Industry 1/2018

Smart Industry 1/2018 - The IoT Business Magazine - powered by Avnet Silica

Smart Industry 1/2018 - The IoT Business Magazine - powered by Avnet Silica

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

and even personal mobile devices<br />

can be added to this growing list of IPenabled<br />

devices.<br />

These connected things become the<br />

tools for a better understanding of all<br />

the factory’s complex processes – and<br />

then using that knowledge to more<br />

rapidly adapt to change. <strong>Smart</strong>er<br />

machines can be better controlled,<br />

thereby increasing efficiency, in what<br />

has come to be called “plant-wide<br />

optimization.”<br />

When it’s a success, IoT is often a combination<br />

of connectivity with realtime<br />

analytics and new cloud services.<br />

The result can include an increase in<br />

manufacturing output, higher uptimes,<br />

more flexible manufacturing, and lower<br />

costs from the consolidation of siloed<br />

systems and proprietary networks.<br />

Securing the new architectures from<br />

attack is becoming more important as<br />

more of the factory floor devices get<br />

connected. Hooking up these devices<br />

to the whole enterprise is a noble goal<br />

but it means an increasing number of<br />

operations can become the focus of<br />

attacks. Reducing risk in today’s largely<br />

unprotected plants is the direct result<br />

of bringing in new security solutions.<br />

Still questions proliferate. Can IoT help<br />

with deploying a converged network<br />

infrastructure? Help manufacturers<br />

improve business performance? Simplify<br />

the network architecture and<br />

build IT-friendly machines?<br />

Those advocating IoT inside the factory<br />

are looking for some key goals:<br />

Lowering total cost of ownership:<br />

A single network architecture and<br />

open standards help to eliminate the<br />

costs associated with multiple isolated<br />

networks and proprietary systems.<br />

Improve operational responsiveness:<br />

Deeper insight into operations<br />

and real-time collaboration between<br />

manufacturing, engineering, and<br />

suppliers improves the quality of<br />

decisions and helps manufacturers<br />

to quickly and efficiently adapt to<br />

changing business requirements and<br />

supply-chain management needs.<br />

Reduce time to market: By replacing<br />

a multi-tier networking strategy with<br />

one standard network architecture,<br />

OEMs can reduce the time it takes to<br />

design, develop, and deliver machines.<br />

Manufacturers, meanwhile, can reduce<br />

their time to market with fewer integration<br />

risks and better visibility into data.<br />

Protect critical manufacturing systems:<br />

The development of a comprehensive<br />

security model while<br />

enabling secure information visibility<br />

and access across production lines.<br />

Putting it all together<br />

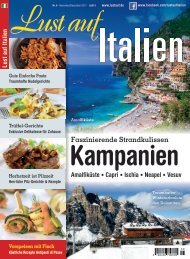

Factory wireless<br />

solutions create new<br />

flexible communication<br />

opportunities between<br />

things, machines,<br />

databases, and people<br />

throughout the plant<br />

Dieter Zetsche, chairman of Daimler,<br />

says that the pace of acceleration in<br />

manufacturing is changing so quickly<br />

that he expects to see more changes on<br />

the factory floor in the next ten years<br />

than we’ve seen in the last 100 years.<br />

If you look at the movement toward<br />

smart manufacturing, many leading<br />

companies are deploying new, more<br />

intelligent, connected machines driving<br />

significant output and productivity<br />

gains as substantial as in previous<br />

industrial revolutions, like the impact<br />

of the steam engine. It’s a pretty<br />

exciting time in manufacturing.<br />

It’s time to look at the Internet of<br />

Things as a key enabler in manufacturing,<br />

not just the trends but some<br />

concrete solutions and use cases that<br />

can be deployed to help get started in<br />

capturing some of that value.<br />

Looking at what’s connected today,<br />

it is apparent that an inflection point<br />

was passed near the beginning<br />

photo ©: Fanuc<br />

85