MSP Issue 32

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

NEWS<br />

Fully Automatic Weighing and Batching of Fish and<br />

Seafood Reduce Production Costs<br />

ààDANISH FISH TECH GROUP<br />

In the fish and seafood industry, products from the processing lines must be weighed and<br />

batched for delivery. Accordingly, speed and accuracy are key factors to optimise production.<br />

To meet the demands, Cabinplant is presenting a fully automated solution for weighing and<br />

batching large portions of fish and seafood ensuring five times less give-away and thereby,<br />

reducing production costs.<br />

at 20 kilos,” says Søren Hansen. He<br />

continues:<br />

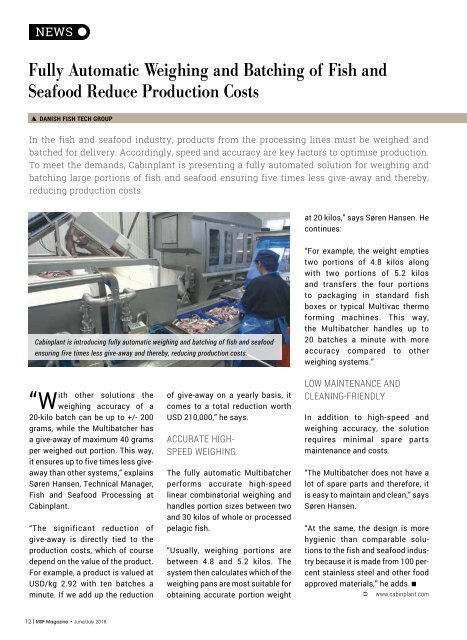

Cabinplant is introducing fully automatic weighing and batching of fish and seafood<br />

ensuring five times less give-away and thereby, reducing production costs.<br />

“For example, the weight empties<br />

two portions of 4.8 kilos along<br />

with two portions of 5.2 kilos<br />

and transfers the four portions<br />

to packaging in standard fish<br />

boxes or typical Multivac thermo<br />

forming machines. This way,<br />

the Multibatcher handles up to<br />

20 batches a minute with more<br />

accuracy compared to other<br />

weighing systems.”<br />

ith other solutions the<br />

“Wweighing accuracy of a<br />

20-kilo batch can be up to +/- 200<br />

grams, while the Multibatcher has<br />

a give-away of maximum 40 grams<br />

per weighed out portion. This way,<br />

it ensures up to five times less giveaway<br />

than other systems,” explains<br />

Søren Hansen, Technical Manager,<br />

Fish and Seafood Processing at<br />

Cabinplant.<br />

“The significant reduction of<br />

give-away is directly tied to the<br />

production costs, which of course<br />

depend on the value of the product.<br />

For example, a product is valued at<br />

USD/kg 2.92 with ten batches a<br />

minute. If we add up the reduction<br />

of give-away on a yearly basis, it<br />

comes to a total reduction worth<br />

USD 210,000,” he says.<br />

ACCURATE HIGH-<br />

SPEED WEIGHING<br />

The fully automatic Multibatcher<br />

performs accurate high-speed<br />

linear combinatorial weighing and<br />

handles portion sizes between two<br />

and 30 kilos of whole or processed<br />

pelagic fish.<br />

“Usually, weighing portions are<br />

between 4.8 and 5.2 kilos. The<br />

system then calculates which of the<br />

weighing pans are most suitable for<br />

obtaining accurate portion weight<br />

LOW MAINTENANCE AND<br />

CLEANING-FRIENDLY<br />

In addition to high-speed and<br />

weighing accuracy, the solution<br />

requires minimal spare parts<br />

maintenance and costs.<br />

“The Multibatcher does not have a<br />

lot of spare parts and therefore, it<br />

is easy to maintain and clean,” says<br />

Søren Hansen.<br />

“At the same, the design is more<br />

hygienic than comparable solutions<br />

to the fish and seafood industry<br />

because it is made from 100 percent<br />

stainless steel and other food<br />

approved materials,” he adds.<br />

Â<br />

www.cabinplant.com<br />

12 | <strong>MSP</strong> Magazine • June/July 2018