cpp - Process technology for the chemical industry 02.2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Unity copes with diversity<br />

As Bigvand emphasises, “Our customers’<br />

challenges clearly show that only unity can<br />

cope with diversity”. This is ensured by EB’s<br />

unified plant data model. All core disciplines,<br />

from basic engineering with FEED up to<br />

<strong>the</strong> pre-commissioning cause & effect<br />

check, use it jointly, in parallel and even<br />

simultaneously. They can base <strong>the</strong>ir specifications<br />

directly on <strong>the</strong> in<strong>for</strong>mation that colleagues<br />

from o<strong>the</strong>r departments have just<br />

created, because <strong>the</strong>y see it immediately<br />

with no need <strong>for</strong> data transfers and interfaces<br />

or <strong>for</strong> synchronisation.<br />

It is also much easier to integrate simulation,<br />

ERP or 3D systems, <strong>for</strong> instance, if<br />

unity exists. A web connection <strong>for</strong> cloud<br />

and app engineering additionally facilitates<br />

worldwide collaboration and makes it more<br />

flexible.<br />

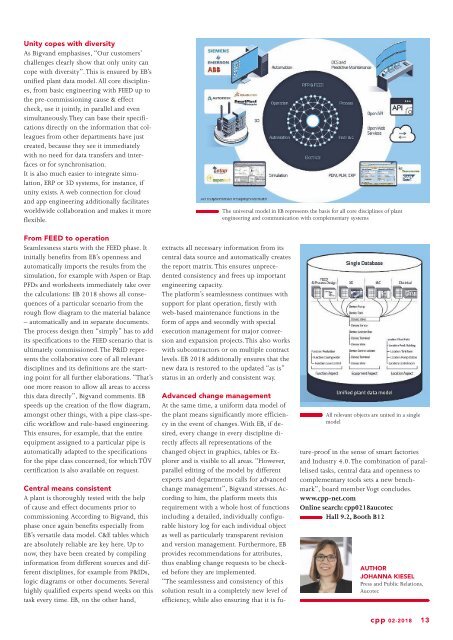

The universal model in EB represents <strong>the</strong> basis <strong>for</strong> all core disciplines of plant<br />

engineering and communication with complementary systems<br />

From FEED to operation<br />

Seamlessness starts with <strong>the</strong> FEED phase. It<br />

initially benefits from EB’s openness and<br />

automatically imports <strong>the</strong> results from <strong>the</strong><br />

simulation, <strong>for</strong> example with Aspen or Etap.<br />

PFDs and worksheets immediately take over<br />

<strong>the</strong> calculations: EB 2018 shows all consequences<br />

of a particular scenario from <strong>the</strong><br />

rough flow diagram to <strong>the</strong> material balance<br />

– automatically and in separate documents.<br />

The process design <strong>the</strong>n “simply” has to add<br />

its specifications to <strong>the</strong> FEED scenario that is<br />

ultimately commissioned. The P&ID represents<br />

<strong>the</strong> collaborative core of all relevant<br />

disciplines and its definitions are <strong>the</strong> starting<br />

point <strong>for</strong> all fur<strong>the</strong>r elaborations. “That’s<br />

one more reason to allow all areas to access<br />

this data directly”, Bigvand comments. EB<br />

speeds up <strong>the</strong> creation of <strong>the</strong> flow diagram,<br />

amongst o<strong>the</strong>r things, with a pipe class-specific<br />

workflow and rule-based engineering.<br />

This ensures, <strong>for</strong> example, that <strong>the</strong> entire<br />

equipment assigned to a particular pipe is<br />

automatically adapted to <strong>the</strong> specifications<br />

<strong>for</strong> <strong>the</strong> pipe class concerned, <strong>for</strong> which TÜV<br />

certification is also available on request.<br />

Central means consistent<br />

A plant is thoroughly tested with <strong>the</strong> help<br />

of cause and effect documents prior to<br />

commissioning. According to Bigvand, this<br />

phase once again benefits especially from<br />

EB’s versatile data model. C&E tables which<br />

are absolutely reliable are key here. Up to<br />

now, <strong>the</strong>y have been created by compiling<br />

in<strong>for</strong>mation from different sources and different<br />

disciplines, <strong>for</strong> example from P&IDs,<br />

logic diagrams or o<strong>the</strong>r documents. Several<br />

highly qualified experts spend weeks on this<br />

task every time. EB, on <strong>the</strong> o<strong>the</strong>r hand,<br />

extracts all necessary in<strong>for</strong>mation from its<br />

central data source and automatically creates<br />

<strong>the</strong> report matrix. This ensures unprecedented<br />

consistency and frees up important<br />

engineering capacity.<br />

The plat<strong>for</strong>m’s seamlessness continues with<br />

support <strong>for</strong> plant operation, firstly with<br />

web-based maintenance functions in <strong>the</strong><br />

<strong>for</strong>m of apps and secondly with special<br />

execution management <strong>for</strong> major conversion<br />

and expansion projects. This also works<br />

with subcontractors or on multiple contract<br />

levels. EB 2018 additionally ensures that <strong>the</strong><br />

new data is restored to <strong>the</strong> updated “as is”<br />

status in an orderly and consistent way.<br />

All relevant objects are united in a single<br />

model<br />

Advanced change management<br />

At <strong>the</strong> same time, a uni<strong>for</strong>m data model of<br />

<strong>the</strong> plant means significantly more efficiency<br />

in <strong>the</strong> event of changes. With EB, if desired,<br />

every change in every discipline directly<br />

affects all representations of <strong>the</strong><br />

changed object in graphics, tables or Explorer<br />

and is visible to all areas. “However,<br />

parallel editing of <strong>the</strong> model by different<br />

experts and departments calls <strong>for</strong> advanced<br />

change management”, Bigvand stresses. According<br />

to him, <strong>the</strong> plat<strong>for</strong>m meets this<br />

requirement with a whole host of functions<br />

including a detailed, individually configurable<br />

history log <strong>for</strong> each individual object<br />

as well as particularly transparent revision<br />

and version management. Fur<strong>the</strong>rmore, EB<br />

provides recommendations <strong>for</strong> attributes,<br />

thus enabling change requests to be checked<br />

be<strong>for</strong>e <strong>the</strong>y are implemented.<br />

“The seamlessness and consistency of this<br />

solution result in a completely new level of<br />

efficiency, while also ensuring that it is future-proof<br />

in <strong>the</strong> sense of smart factories<br />

and Industry 4.0. The combination of parallelised<br />

tasks, central data and openness to<br />

complementary tools sets a new benchmark”,<br />

board member Vogt concludes.<br />

www.<strong>cpp</strong>-net.com<br />

Online search: <strong>cpp</strong>0218aucotec<br />

Hall 9.2, Booth B12<br />

AUTHOR:<br />

JOHANNA KIESEL<br />

Press and Public Relations,<br />

Aucotec<br />

<strong>cpp</strong> 02-2018 13