cpp - Process technology for the chemical industry 02.2018

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Picture: KSB<br />

High-efficiency motor<br />

Toge<strong>the</strong>r with scientists from Karlsruhe Institute of<br />

Technology, KSB specialists developed a very compact<br />

22-kW synchronous reluctance motor. Semiconductor<br />

<strong>technology</strong> facilitates <strong>the</strong> cooling management that ensures<br />

removal of heat emerging from <strong>the</strong> power electronics.<br />

The element’s volume could be reduced by<br />

25 %, due to <strong>the</strong> integrated frequency inverter. The<br />

drive exists as prototype, which was built to demonstrate<br />

<strong>the</strong> potential of silicon carbide components in<br />

terms of higher motor ratings. While most of <strong>the</strong> stand -<br />

ardised pumps operate at constant motor speed with an<br />

impeller, that has been mechanically trimmed <strong>for</strong> <strong>the</strong><br />

desired operation point, this motor operates with a<br />

„virtually trimmed impeller“. Thus trimming is even<br />

possible after <strong>the</strong> pump set has been commissioned.<br />

www.<strong>cpp</strong>-net.com<br />

Online search: <strong>cpp</strong>0218ksb<br />

Hall 8.0, Booth H14<br />

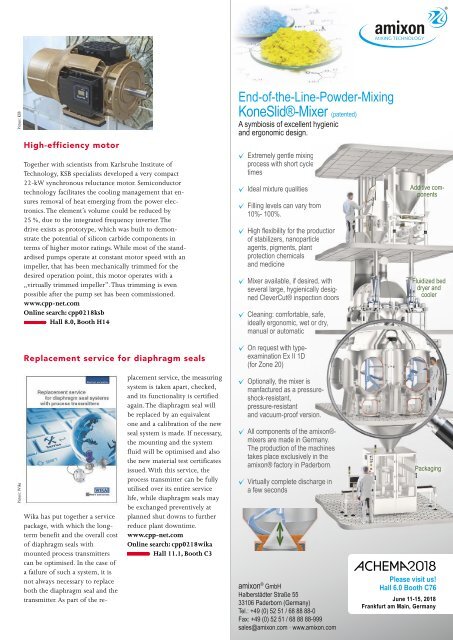

End-of-<strong>the</strong>-Line-Powder-Mixing<br />

KoneSlid®-Mixer (patented)<br />

A symbiosis of excellent hygienic<br />

and ergonomic design.<br />

✓<br />

Extremely gentle mixing<br />

process with short cycle<br />

times<br />

✓ Ideal mixture qualities<br />

✓<br />

✓<br />

✓<br />

✓<br />

Filling levels can vary from<br />

10%- 100%.<br />

<br />

of stabilizers, nanoparticle<br />

agents, pigments, plant<br />

protection <strong>chemical</strong>s<br />

and medicine<br />

Mixer available, if desired, with<br />

several large, hygienically designed<br />

CleverCut® inspection doors<br />

Cleaning: com<strong>for</strong>table, safe,<br />

ideally ergonomic, wet or dry,<br />

manual or automatic<br />

Additive components<br />

Fluidized bed<br />

dryer and<br />

cooler<br />

Picture: Wika<br />

Replacement service <strong>for</strong> diaphragm seals<br />

Wika has put toge<strong>the</strong>r a service<br />

package, with which <strong>the</strong> longterm<br />

benefit and <strong>the</strong> overall cost<br />

of diaphragm seals with<br />

mounted process transmitters<br />

can be optimised. In <strong>the</strong> case of<br />

a failure of such a system, it is<br />

not always necessary to replace<br />

both <strong>the</strong> diaphragm seal and <strong>the</strong><br />

transmitter. As part of <strong>the</strong> replacement<br />

service, <strong>the</strong> measuring<br />

system is taken apart, checked,<br />

and its functionality is certified<br />

again. The diaphragm seal will<br />

be replaced by an equivalent<br />

one and a calibration of <strong>the</strong> new<br />

seal system is made. If necessary,<br />

<strong>the</strong> mounting and <strong>the</strong> system<br />

fluid will be optimised and also<br />

<strong>the</strong> new material test certificates<br />

issued. With this service, <strong>the</strong><br />

process transmitter can be fully<br />

utilised over its entire service<br />

life, while diaphragm seals may<br />

be exchanged preventively at<br />

planned shut downs to fur<strong>the</strong>r<br />

reduce plant downtime.<br />

www.<strong>cpp</strong>-net.com<br />

Online search: <strong>cpp</strong>0218wika<br />

Hall 11.1, Booth C3<br />

✓<br />

✓<br />

✓<br />

✓<br />

On request with typeexamination<br />

Ex II 1D<br />

(<strong>for</strong> Zone 20)<br />

Optionally, <strong>the</strong> mixer is<br />

manfactured as a pressureshock-resistant,<br />

pressure-resistant<br />

and vacuum-proof version.<br />

All components of <strong>the</strong> amixon®mixers<br />

are made in Germany.<br />

The production of <strong>the</strong> machines<br />

takes place exclusively in <strong>the</strong><br />

amixon® factory in Paderborn.<br />

Virtually complete discharge in<br />

a few seconds<br />

amixon ® GmbH<br />

Halberstädter Straße 55<br />

33106 Paderborn (Germany)<br />

Tel.: +49 (0) 52 51 / 68 88 88-0<br />

Fax: +49 (0) 52 51 / 68 88 88-999<br />

sales@amixon.com · www.amixon.com<br />

Packaging<br />

Please visit us!<br />

Hall 6.0 Booth C76<br />

June 11-15, 2018<br />

Frankfurt am Main, Germany<br />

<strong>cpp</strong> 02-2018 33