cpp - Process technology for the chemical industry 02.2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

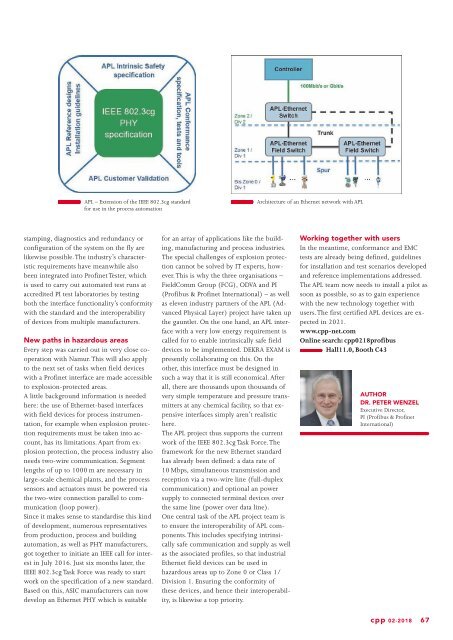

APL – Extension of <strong>the</strong> IEEE 802.3cg standard<br />

<strong>for</strong> use in <strong>the</strong> process automation<br />

Architecture of an E<strong>the</strong>rnet network with APL<br />

stamping, diagnostics and redundancy or<br />

configuration of <strong>the</strong> system on <strong>the</strong> fly are<br />

likewise possible. The <strong>industry</strong>’s characteristic<br />

requirements have meanwhile also<br />

been integrated into Profinet Tester, which<br />

is used to carry out automated test runs at<br />

accredited PI test laboratories by testing<br />

both <strong>the</strong> interface functionality’s con<strong>for</strong>mity<br />

with <strong>the</strong> standard and <strong>the</strong> interoperability<br />

of devices from multiple manufacturers.<br />

New paths in hazardous areas<br />

Every step was carried out in very close cooperation<br />

with Namur. This will also apply<br />

to <strong>the</strong> next set of tasks when field devices<br />

with a Profinet interface are made accessible<br />

to explosion-protected areas.<br />

A little background in<strong>for</strong>mation is needed<br />

here: <strong>the</strong> use of E<strong>the</strong>rnet-based interfaces<br />

with field devices <strong>for</strong> process instrumentation,<br />

<strong>for</strong> example when explosion protection<br />

requirements must be taken into account,<br />

has its limitations. Apart from explosion<br />

protection, <strong>the</strong> process <strong>industry</strong> also<br />

needs two-wire communication. Segment<br />

lengths of up to 1000 m are necessary in<br />

large-scale <strong>chemical</strong> plants, and <strong>the</strong> process<br />

sensors and actuators must be powered via<br />

<strong>the</strong> two-wire connection parallel to communication<br />

(loop power).<br />

Since it makes sense to standardise this kind<br />

of development, numerous representatives<br />

from production, process and building<br />

automation, as well as PHY manufacturers,<br />

got toge<strong>the</strong>r to initiate an IEEE call <strong>for</strong> interest<br />

in July 2016. Just six months later, <strong>the</strong><br />

IEEE 802.3cg Task Force was ready to start<br />

work on <strong>the</strong> specification of a new standard.<br />

Based on this, ASIC manufacturers can now<br />

develop an E<strong>the</strong>rnet PHY which is suitable<br />

<strong>for</strong> an array of applications like <strong>the</strong> building,<br />

manufacturing and process industries.<br />

The special challenges of explosion protection<br />

cannot be solved by IT experts, however.<br />

This is why <strong>the</strong> three organisations –<br />

FieldComm Group (FCG), ODVA and PI<br />

(Profibus & Profinet International) – as well<br />

as eleven <strong>industry</strong> partners of <strong>the</strong> APL (Advanced<br />

Physical Layer) project have taken up<br />

<strong>the</strong> gauntlet. On <strong>the</strong> one hand, an APL interface<br />

with a very low energy requirement is<br />

called <strong>for</strong> to enable intrinsically safe field<br />

devices to be implemented. DEKRA EXAM is<br />

presently collaborating on this. On <strong>the</strong><br />

o<strong>the</strong>r, this interface must be designed in<br />

such a way that it is still economical. After<br />

all, <strong>the</strong>re are thousands upon thousands of<br />

very simple temperature and pressure transmitters<br />

at any <strong>chemical</strong> facility, so that expensive<br />

interfaces simply aren’t realistic<br />

here.<br />

The APL project thus supports <strong>the</strong> current<br />

work of <strong>the</strong> IEEE 802.3cg Task Force. The<br />

framework <strong>for</strong> <strong>the</strong> new E<strong>the</strong>rnet standard<br />

has already been defined: a data rate of<br />

10 Mbps, simultaneous transmission and<br />

reception via a two-wire line (full-duplex<br />

communication) and optional an power<br />

supply to connected terminal devices over<br />

<strong>the</strong> same line (power over data line).<br />

One central task of <strong>the</strong> APL project team is<br />

to ensure <strong>the</strong> interoperability of APL components.<br />

This includes specifying intrinsically<br />

safe communication and supply as well<br />

as <strong>the</strong> associated profiles, so that industrial<br />

E<strong>the</strong>rnet field devices can be used in<br />

hazardous areas up to Zone 0 or Class 1/<br />

Division 1. Ensuring <strong>the</strong> con<strong>for</strong>mity of<br />

<strong>the</strong>se devices, and hence <strong>the</strong>ir interoperability,<br />

is likewise a top priority.<br />

Working toge<strong>the</strong>r with users<br />

In <strong>the</strong> meantime, con<strong>for</strong>mance and EMC<br />

tests are already being defined, guidelines<br />

<strong>for</strong> installation and test scenarios developed<br />

and reference implementations addressed.<br />

The APL team now needs to install a pilot as<br />

soon as possible, so as to gain experience<br />

with <strong>the</strong> new <strong>technology</strong> toge<strong>the</strong>r with<br />

users. The first certified APL devices are expected<br />

in 2021.<br />

www.<strong>cpp</strong>-net.com<br />

Online search: <strong>cpp</strong>0218profibus<br />

Hall11.0, Booth C43<br />

AUTHOR:<br />

DR. PETER WENZEL<br />

Executive Director,<br />

PI (Profibus & Profinet<br />

International)<br />

<strong>cpp</strong> 02-2018 67