cpp - Process technology for the chemical industry 02.2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

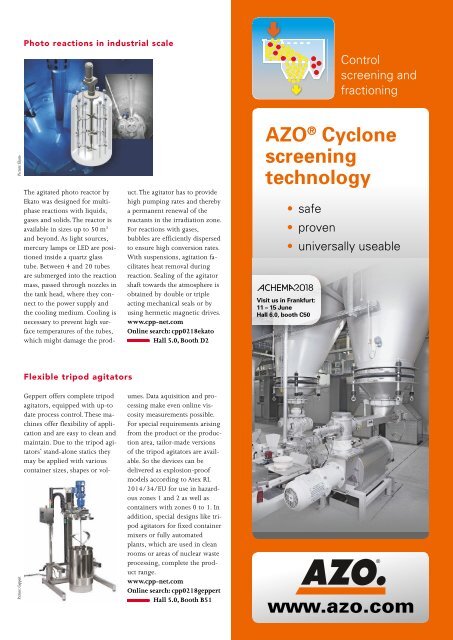

Photo reactions in industrial scale<br />

Picture: Ekato<br />

The agitated photo reactor by<br />

Ekato was designed <strong>for</strong> multiphase<br />

reactions with liquids,<br />

gases and solids. The reactor is<br />

available in sizes up to 50 m 3<br />

and beyond. As light sources,<br />

mercury lamps or LED are positioned<br />

inside a quartz glass<br />

tube. Between 4 and 20 tubes<br />

are submerged into <strong>the</strong> reaction<br />

mass, passed through nozzles in<br />

<strong>the</strong> tank head, where <strong>the</strong>y connect<br />

to <strong>the</strong> power supply and<br />

<strong>the</strong> cooling medium. Cooling is<br />

necessary to prevent high surface<br />

temperatures of <strong>the</strong> tubes,<br />

which might damage <strong>the</strong> product.<br />

The agitator has to provide<br />

high pumping rates and <strong>the</strong>reby<br />

a permanent renewal of <strong>the</strong><br />

reactants in <strong>the</strong> irradiation zone.<br />

For reactions with gases,<br />

bubbles are efficiently dispersed<br />

to ensure high conversion rates.<br />

With suspensions, agitation facilitates<br />

heat removal during<br />

reaction. Sealing of <strong>the</strong> agitator<br />

shaft towards <strong>the</strong> atmosphere is<br />

obtained by double or triple<br />

acting mechanical seals or by<br />

using hermetic magnetic drives.<br />

www.<strong>cpp</strong>-net.com<br />

Online search: <strong>cpp</strong>0218ekato<br />

Hall 5.0, Booth D2<br />

Flexible tripod agitators<br />

Picture: Geppert<br />

Geppert offers complete tripod<br />

agitators, equipped with up-to<br />

date process control. These machines<br />

offer flexibility of application<br />

and are easy to clean and<br />

maintain. Due to <strong>the</strong> tripod agitators’<br />

stand-alone statics <strong>the</strong>y<br />

may be applied with various<br />

container sizes, shapes or volumes.<br />

Data aquisition and processing<br />

make even online viscosity<br />

measurements possible.<br />

For special requirements arising<br />

from <strong>the</strong> product or <strong>the</strong> production<br />

area, tailor-made versions<br />

of <strong>the</strong> tripod agitators are available.<br />

So <strong>the</strong> devices can be<br />

delivered as explosion-proof<br />

models according to Atex RL<br />

2014/34/EU <strong>for</strong> use in hazardous<br />

zones 1 and 2 as well as<br />

containers with zones 0 to 1. In<br />

addition, special designs like tripod<br />

agitators <strong>for</strong> fixed container<br />

mixers or fully automated<br />

plants, which are used in clean<br />

rooms or areas of nuclear waste<br />

processing, complete <strong>the</strong> product<br />

range.<br />

www.<strong>cpp</strong>-net.com<br />

Online search: <strong>cpp</strong>0218geppert<br />

Hall 5.0, Booth B51<br />

<strong>cpp</strong> 02-2018 37