cpp - Process technology for the chemical industry 02.2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>cpp</strong> ACHEMA PUMPS<br />

Let’s get back to <strong>the</strong> rotors. What kinds of design are available?<br />

Hahn: We equip our pumps with axial or semi-axial rotors, which<br />

are also called centrifugal rotors, depending on <strong>the</strong> customer’s<br />

needs.<br />

When is which kind of rotor used?<br />

Hahn: We recommend axial rotors <strong>for</strong> applications where a high<br />

delivery rate is desired. Semi-axial rotors are preferred whenever<br />

<strong>the</strong> medium needs to be conveyed over long distances at high pressure<br />

or if it has to overcome a big difference in height.<br />

In which materials does Flux offer its 400 series drum and<br />

container pumps?<br />

Hahn: That depends firstly on <strong>the</strong>ir resistance to <strong>the</strong> media to be<br />

conveyed and secondly on whe<strong>the</strong>r <strong>the</strong> pumps will be operated in<br />

explosion hazard areas. The spectrum of possible materials <strong>for</strong> components<br />

that come into contact with <strong>the</strong> product ranges from polypropylene<br />

or polyvinylidene fluoride to aluminium and stainless<br />

steel or Hastelloy C.<br />

The F/FP 430 vertical pump with a<br />

mechanical seal can be quickly disassembled<br />

into interior and exterior pipes<br />

Are all pumps approved <strong>for</strong> use in explosion hazard areas?<br />

Hahn: No. The F/FP 427 hygiene pump, which can be fully disassembled,<br />

and all plastic pumps like <strong>the</strong> F 430 PP 100/50 container<br />

pump, which is made of polypropylene, must not be used in explosion<br />

hazard areas. Apart from <strong>the</strong>se, all o<strong>the</strong>r pumps in <strong>the</strong> 400 series<br />

and made of stainless steel or Hastelloy C have Atex approval.<br />

Not even <strong>the</strong> best pumps can function without a drive. What<br />

options does Flux offer <strong>for</strong> <strong>the</strong> 400 series?<br />

Hahn: Depending on <strong>the</strong> customer’s needs, <strong>the</strong> pumps ei<strong>the</strong>r have<br />

an electric or a pneumatic drive. Of course, <strong>the</strong> highest demand is<br />

<strong>for</strong> electric drives and above all commutator motors.<br />

Which Flux also manufactures in-house.<br />

Hahn: That’s right. We manufacture <strong>the</strong>m ourselves here in Maulbronn.<br />

Why does <strong>the</strong> company make its own motors?<br />

Hahn: For quality and flexibility reasons. Our customers value <strong>the</strong><br />

high quality of our products. By manufacturing our own commutator<br />

motors and implementing our own accompanying quality man -<br />

agement system, we can keep a handle on quality ourselves. In addition,<br />

we can react very flexibly to different country-specific requirements<br />

with respect to <strong>the</strong> voltage and frequency at which <strong>the</strong><br />

motors can be operated.<br />

Jürgen Rabenseifner: By producing our own motors, we’re better<br />

able to react to customer requirements. I’m thinking of one case we<br />

recently handled <strong>for</strong> customers from <strong>the</strong> Middle East. They were<br />

looking <strong>for</strong> an explosion protected pump unit that could be operat -<br />

ed up to an ambient temperature of +60 °C. The Atex approval only<br />

covers a temperature range up to +40 °C. With this requirement in<br />

mind, we developed our explosion protected F 460 Ex commutator<br />

motor to handle <strong>the</strong> desired ambient temperature. Then we had PTB<br />

certify <strong>the</strong> entire pump unit, consisting of <strong>the</strong> F 460 Ex HT motor<br />

and <strong>the</strong> sealless F/FP 424 (HT) pump, in accordance with Atex requirements.<br />

The 400 series also includes so-called pump sets. Mr. Raben -<br />

seifner, what are <strong>the</strong>se sets exactly?<br />

Rabenseifner: They’re pre-configured units consisting of a pump,<br />

motor, hose and pump nozzle. They offer two major advantages <strong>for</strong><br />

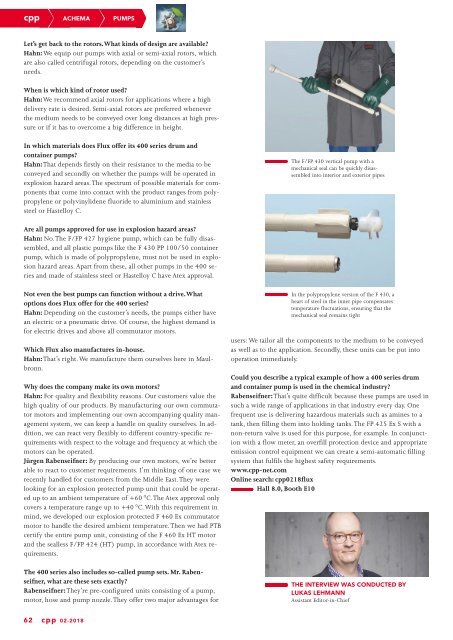

In <strong>the</strong> polypropylene version of <strong>the</strong> F 430, a<br />

heart of steel in <strong>the</strong> inner pipe compensates<br />

temperature fluctuations, ensuring that <strong>the</strong><br />

mechanical seal remains tight<br />

users: We tailor all <strong>the</strong> components to <strong>the</strong> medium to be conveyed<br />

as well as to <strong>the</strong> application. Secondly, <strong>the</strong>se units can be put into<br />

operation immediately.<br />

Could you describe a typical example of how a 400 series drum<br />

and container pump is used in <strong>the</strong> <strong>chemical</strong> <strong>industry</strong>?<br />

Rabenseifner: That’s quite difficult because <strong>the</strong>se pumps are used in<br />

such a wide range of applications in that <strong>industry</strong> every day. One<br />

frequent use is delivering hazardous materials such as amines to a<br />

tank, <strong>the</strong>n filling <strong>the</strong>m into holding tanks. The FP 425 Ex S with a<br />

non-return valve is used <strong>for</strong> this purpose, <strong>for</strong> example. In conjunct -<br />

ion with a flow meter, an overfill protection device and appropriate<br />

emission control equipment we can create a semi-automatic filling<br />

system that fulfils <strong>the</strong> highest safety requirements.<br />

www.<strong>cpp</strong>-net.com<br />

Online search: <strong>cpp</strong>0218flux<br />

Hall 8.0, Booth E10<br />

THE INTERVIEW WAS CONDUCTED BY:<br />

LUKAS LEHMANN<br />

Assistant Editor-in-Chief<br />

62 <strong>cpp</strong> 02-2018