IATSE 3rd 2019_web

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

machine must familiarize themselves<br />

with the new equiptment. Workers<br />

should be aware of this change because<br />

it directly affects their responsibilities<br />

as an operator. Employers’ “safe use<br />

program” should outline these policies<br />

and procedures for how workers are to<br />

follow these guidelines. <strong>IATSE</strong> workers<br />

should review the companion training<br />

requirements and be sure that they<br />

have been properly trained on each lift<br />

they intend to use. If you think your<br />

employer is skimping on developing<br />

safety plans, now is a great time to act<br />

by notifying your local union. ANSI<br />

A92 requires the implementation of<br />

a rescue plan that is specific to the<br />

worksite and equipment.<br />

The employers’ safe use program<br />

must also contain planning for<br />

identifying hazards, evaluating risks,<br />

establishing control measures, and<br />

communicating to the workers. It must<br />

evaluate the worksite. And, it must have<br />

a rescue plan which covers everything<br />

from how to lower a lift which has<br />

lost power to high angle rescue and<br />

emergency services.<br />

MANUFACTURING/DESIGN<br />

ANSI A92.20 will also bring a<br />

plethora of equipment changes, many<br />

of which consist of adding sensors,<br />

sensors, and more sensors! All lifts<br />

manufactured after the standard must<br />

add at least two new sensors; one to<br />

detect when the load limit has exceeded<br />

its safe weight, and another to detect<br />

when the lift’s tilt surpasses a certain<br />

slope. Outdoor lifts will require an<br />

additional sensor to detect wind speed.<br />

The required height for work platform<br />

railings will also be raised from 39in<br />

to 43.5in, and MEWPs used on rough<br />

surfaces must change their tires from<br />

air to solid/foam-filled.<br />

ANSI hopes these equipment<br />

improvements will help eliminate many<br />

hazards that occur while using MEWPs.<br />

Please note, however, that the standard<br />

does not affect aerial lifts manufactured<br />

prior to its implementation. Older lifts<br />

do not need to be updated or modified.<br />

Instead, operators should be aware<br />

of the exact piece of equipment they<br />

are utilizing along with its specific<br />

functions.<br />

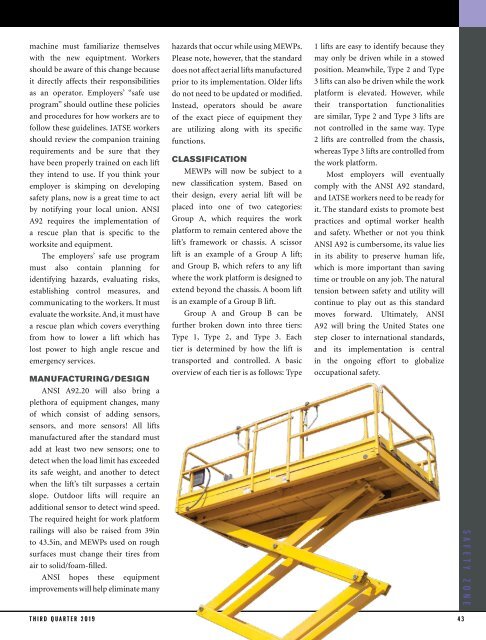

CLASSIFICATION<br />

MEWPs will now be subject to a<br />

new classification system. Based on<br />

their design, every aerial lift will be<br />

placed into one of two categories:<br />

Group A, which requires the work<br />

platform to remain centered above the<br />

lift’s framework or chassis. A scissor<br />

lift is an example of a Group A lift;<br />

and Group B, which refers to any lift<br />

where the work platform is designed to<br />

extend beyond the chassis. A boom lift<br />

is an example of a Group B lift.<br />

Group A and Group B can be<br />

further broken down into three tiers:<br />

Type 1, Type 2, and Type 3. Each<br />

tier is determined by how the lift is<br />

transported and controlled. A basic<br />

overview of each tier is as follows: Type<br />

1 lifts are easy to identify because they<br />

may only be driven while in a stowed<br />

position. Meanwhile, Type 2 and Type<br />

3 lifts can also be driven while the work<br />

platform is elevated. However, while<br />

their transportation functionalities<br />

are similar, Type 2 and Type 3 lifts are<br />

not controlled in the same way. Type<br />

2 lifts are controlled from the chassis,<br />

whereas Type 3 lifts are controlled from<br />

the work platform.<br />

Most employers will eventually<br />

comply with the ANSI A92 standard,<br />

and <strong>IATSE</strong> workers need to be ready for<br />

it. The standard exists to promote best<br />

practices and optimal worker health<br />

and safety. Whether or not you think<br />

ANSI A92 is cumbersome, its value lies<br />

in its ability to preserve human life,<br />

which is more important than saving<br />

time or trouble on any job. The natural<br />

tension between safety and utility will<br />

continue to play out as this standard<br />

moves forward. Ultimately, ANSI<br />

A92 will bring the United States one<br />

step closer to international standards,<br />

and its implementation is central<br />

in the ongoing effort to globalize<br />

occupational safety.<br />

SAFETY ZONE<br />

THIRD QUARTER <strong>2019</strong> 43