- Page 1:

Driving the industry towards digita

- Page 4 and 5:

PURPOSE LED, PERFORMANCE DRIVEN The

- Page 6 and 7:

CONTENTS Partnerships, teamwork and

- Page 8 and 9:

94 LifeScan 116 Gojek 136 Aligned 1

- Page 10 and 11:

10 Partnerships, teamwork and the r

- Page 12 and 13:

BROWN-FORMAN Data is at the core of

- Page 14 and 15:

5 Keys to Creating a Data Culture L

- Page 16 and 17:

BROWN-FORMAN 16 traditional data an

- Page 18 and 19:

Whatever you’re trying to solve,

- Page 20 and 21:

BROWN-FORMAN 20 “We really levera

- Page 22 and 23:

BROWN-FORMAN 1870 Year founded $3.3

- Page 24 and 25:

24 “We are judicious with how we

- Page 26 and 27:

LIFTING TECHNOLOGY LEADERS THROUGH

- Page 28 and 29:

BROWN-FORMAN 28 embraced the change

- Page 30 and 31:

LEADERSHIP 30 Becoming an entrepren

- Page 32 and 33:

LEADERSHIP 32 As Chetan Dube, CEO a

- Page 34 and 35:

LEADERSHIP 34 Eugenio Pace, CEO and

- Page 36 and 37:

LEADERSHIP 36 assume that the end i

- Page 38 and 39:

TECHNOLOGY Embracing behaviours 38

- Page 40 and 41:

TECHNOLOGY 40 SocialChorus has earn

- Page 42 and 43:

TECHNOLOGY “As a smaller company,

- Page 44 and 45:

TECHNOLOGY 44 with even 5% less. Th

- Page 46 and 47:

March 19-20, 2020 | Eden Roc, Miami

- Page 48 and 49:

SUPPLY CHAIN 48 DIGITAL INNOVATION

- Page 50 and 51:

SUPPLY CHAIN With technology evolvi

- Page 52 and 53:

SUPPLY CHAIN 52 capacity. In additi

- Page 54 and 55:

SUPPLY CHAIN analytics, UPS has see

- Page 56 and 57:

SUPPLY CHAIN “The future is excit

- Page 58 and 59:

SUSTAINABILITY 58 HOW BUSINESSES CA

- Page 60 and 61:

SUSTAINABILITY 60 In today’s high

- Page 62 and 63:

SUSTAINABILITY 62 “Building a sus

- Page 64 and 65:

SUSTAINABILITY 64 they need to have

- Page 66 and 67:

SUSTAINABILITY “To achieve longev

- Page 68 and 69:

CITY FOCUS | KANSAS CITY 68 City Fo

- Page 70 and 71:

CITY FOCUS | KANSAS CITY 70 Kansas

- Page 72 and 73:

CITY FOCUS | KANSAS CITY 72 MODERN

- Page 74 and 75:

CITY FOCUS | KANSAS CITY 74 Agency

- Page 76 and 77:

CITY FOCUS | KANSAS CITY 76 company

- Page 78 and 79:

TOP 10 78 FEBRUARY 2020

- Page 80 and 81:

TOP 10 HQ IRVING, TEXAS $343.4bn MA

- Page 83 and 84:

TOP 10 HQ NEW BRUNSWICK, NEW JERSEY

- Page 85 and 86:

HQ MENLO PARK, CALIFORNIA $512bn MA

- Page 87 and 88:

TOP 10 HQ OMAHA, NEBRASKA $516.4bn

- Page 89 and 90:

HQ SEATTLE, WASHINGTON $916.1bn MAR

- Page 91 and 92:

HQ REDMOND, WASHINGTON $946.5bn MAR

- Page 93 and 94:

01 Tim Cook APPLE HQ CUPERTINO, CAL

- Page 95 and 96:

www.businesschief.com 95

- Page 97 and 98:

97 1984 Year founded $1.2bn Revenue

- Page 99 and 100:

er ionships are e, delivery is nt a

- Page 101 and 102:

CLICK TO WATCH: ‘LIFESCAN CORPORA

- Page 103 and 104:

Enterprise Services From strategy t

- Page 105 and 106:

105 Miguel Louzan EXECUTIVE PROFILE

- Page 107 and 108:

Digital Strategy & Roadmap We bring

- Page 109 and 110:

109 Although technological implemen

- Page 111:

COMPANY FACTS • 90% of LifeScan

- Page 114 and 115:

LIFESCAN 114 “If you think about

- Page 116 and 117:

116 How cybersecurity promotes trus

- Page 118 and 119:

GOJEK George Do, Chief Information

- Page 120 and 121:

The physical key to your digital se

- Page 122 and 123:

GOJEK 122 “The bad guys only have

- Page 124 and 125:

CRIT

- Page 126 and 127:

SEE AND STOP CYBER THREATS WITH THE

- Page 128 and 129:

GOJEK 2010 Year founded HQ Jakarta

- Page 130 and 131:

GOJEK 130 and merchants,” Do says

- Page 132 and 133:

Protect the entire attack surface w

- Page 134 and 135:

GOJEK 134 war game exercises.” Wh

- Page 136 and 137:

Adaptive Data Centers 136 WRITTEN B

- Page 138 and 139:

ALIGNED Aligned is focused on desig

- Page 140 and 141:

IF YOU HAVE THE NEED, WE HAVE THE S

- Page 142 and 143:

ALIGNED 142 not require additional

- Page 144 and 145:

CRITICAL POWER Legendary Customer S

- Page 146 and 147:

ALIGNED 146 cooling. When Aligned s

- Page 148 and 149:

Delivering Safe, Reliable and Effic

- Page 150 and 151:

ALIGNED COMPANY FACTS • Aligned m

- Page 153 and 154:

Data Center Trends “When you look

- Page 155 and 156:

manufacturer - the CACTUS,” revea

- Page 157 and 158:

157 Ashburn in about six months, wh

- Page 159 and 160:

www.businesschief.com 159

- Page 161 and 162:

161 1968 Year founded $1.6bn Revenu

- Page 163 and 164:

The 4 key points to achieve success

- Page 165 and 166:

CLICK TO WATCH: ‘INTRODUCING BELC

- Page 167 and 168:

cultural change and get inspired by

- Page 169:

“Digital transformation is about

- Page 172 and 173:

BELCORP New challenges, New ideas G

- Page 174 and 175:

BELCORP 174 its mobile application

- Page 176 and 177:

176 Faster, smarter and more profit

- Page 178 and 179:

FICO How FICO’s innovative decisi

- Page 180 and 181:

FICO 180 of the research, focused o

- Page 182 and 183:

FICO 182 mortgages and investments.

- Page 184 and 185:

If you’re not disrupting, you’r

- Page 186 and 187:

FICO 186 CLICK TO WATCH: ‘FICO ®

- Page 188 and 189:

FICO 188 customer experience that t

- Page 190 and 191:

FICO 190 CLICK TO WATCH: ‘JOIN TH

- Page 192 and 193:

FICO 192 FEBRUARY 2020

- Page 194 and 195:

194 Savills Critical Facilities Gro

- Page 196 and 197:

SAVILLS Rick Drescher, Corporate Ma

- Page 198 and 199:

SAVILLS 198 “We’ve talked about

- Page 200 and 201:

SAVILLS 200 at what a project is li

- Page 202 and 203: SAVILLS HYBRID & HYPERSCALE BUILT O

- Page 204 and 205: SAVILLS 204 “During a recent faci

- Page 206 and 207: SAVILLS 206 “The real value of ha

- Page 208 and 209: GOLDEN HIPPO 208 GOLDEN HIPPO DRIVI

- Page 210 and 211: GOLDEN HIPPO FAREEN MEHRZAI, THE AR

- Page 212 and 213: A GLOBAL LEADER IN FREEZE-DRIED PET

- Page 214 and 215: GOLDEN HIPPO 214 “THE MOST EXCITI

- Page 216 and 217: An experience so seamless, you will

- Page 218 and 219: GOLDEN HIPPO 218 them to thrive her

- Page 220 and 221: THERE’S ONE KEY INGREDIENT THAT S

- Page 222 and 223: Focus on packaging The packaging co

- Page 224 and 225: VITA9355_Golden_Hippo_ad_v1.indd 2

- Page 226 and 227: GLOBAL IDEATION && PRODUCT DEVELOPM

- Page 228 and 229: QUALITY FIRST Ion Labs is a Custom

- Page 230 and 231: GOLDEN HIPPO Comprehensive and cust

- Page 232 and 233: Reliance Litho & Label Your Printin

- Page 234 and 235: 236 WAYNE FARMS: THE VALUE OF EXPER

- Page 236 and 237: WAYNE FARMS GLENN SMITH, DIRECTOR O

- Page 238 and 239: TRUSTED GRAIN SUPPLIER At Gavilon,

- Page 240 and 241: WAYNE FARMS 242 employees,” Smith

- Page 242 and 243: Powered to Perform CSX is redefinin

- Page 244 and 245: FROM THE GRAIN UP BY FAMILIES, FOR

- Page 246 and 247: WAYNE FARMS “THEY SAY YOU NEED TH

- Page 248 and 249: 250 TRANSFORMING MANUFACTURING STRA

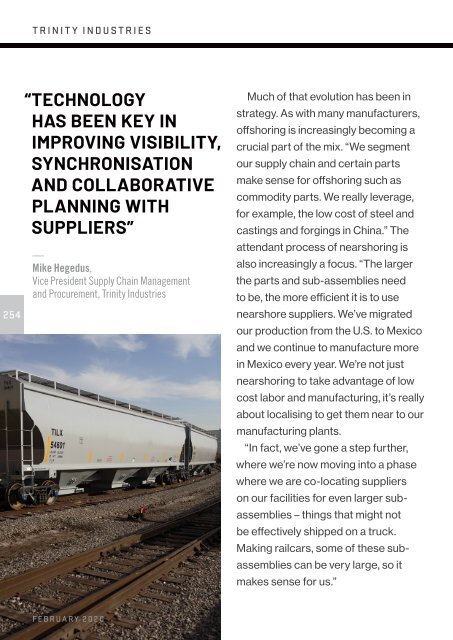

- Page 250 and 251: TRINITY INDUSTRIES MIKE HEGEDUS, VI

- Page 254 and 255: TRINITY INDUSTRIES 256 “WE’VE T

- Page 256 and 257: TRINITY INDUSTRIES 258 Enabling the

- Page 258 and 259: It’s what’s inside that keeps u

- Page 260 and 261: TRINITY INDUSTRIES 262 FEBRUARY 202

- Page 262 and 263: CHANGING THE 264 GAME FOR ENERGY AN

- Page 264 and 265: IBM INDUSTRY ACADEMY IBM is helping

- Page 266 and 267: IBM INDUSTRY ACADEMY 268 Chawla not

- Page 268 and 269: IBM INDUSTRY ACADEMY 270 experiment

- Page 270 and 271: Change is hard. The truth is that m

- Page 272 and 273: IBM INDUSTRY ACADEMY 274 intelligen

- Page 274 and 275: IBM INDUSTRY ACADEMY FACTS IBM on m

- Page 276 and 277: IBM INDUSTRY ACADEMY 278 royalty ho

- Page 278 and 279: IBM INDUSTRY ACADEMY 1911 Year foun

- Page 280 and 281: 282 Leveraging the power of innovat

- Page 282 and 283: POMERLEAU INC Canadian construction

- Page 284 and 285: POMERLEAU INC 286 “Why try to ear

- Page 286 and 287: INTERIOR SYSTEM SPECIALIST TOTALLY

- Page 288 and 289: POMERLEAU INC 290 scheduling, to ge

- Page 290 and 291: INFINITE POTENTIAL Janick Electric

- Page 292 and 293: POMERLEAU INC Established in 2013,

- Page 294 and 295: We make buildings work. WE HANDLE M

- Page 296 and 297: POMERLEAU INC 298 FEBRUARY 2020

- Page 298 and 299: POMERLEAU INC CONCRETE PEOPLE. CONC