AW #131.pdf - Karatunov.net

AW #131.pdf - Karatunov.net

AW #131.pdf - Karatunov.net

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

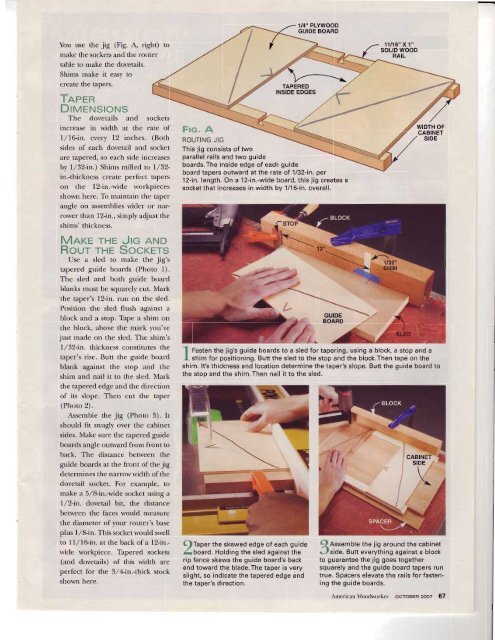

You use the jig (Fig. A, right) to<br />

make the sockets and the router<br />

table to make the dovetails.<br />

Shims make it easy to<br />

create the tapers.<br />

TnpEn<br />

DrvEtrtstoNS<br />

The dovetails and<br />

sides of each dovetail and<br />

sockets<br />

increase in width at the rate of<br />

l/lGin. every 12 inches. (Both<br />

socket<br />

are tapered, so each side increases<br />

by I/32-in.) Shims milled to I/32-<br />

in.-thickness create perfect uPers<br />

on the l2-in.-wide workpieces<br />

shown here. To maintain the taper<br />

angle on assemblies wider or nar-<br />

rower than 12-in., simply adjust the<br />

shims' thickness.<br />

Mnrce rHE Jtc AND<br />

Rour rHE SocKETS<br />

Use a sled to make the jig's<br />

tapered guide boards (Photo 1).<br />

The sled and both guide board<br />

blanks must be squarely cut. Mark<br />

the taper's l2-in. run on the sled.<br />

Position the sled flush against a<br />

block and a stop. Thpe a shim on<br />

the block, above the mark you've<br />

just made on the sled. The shim's<br />

l/32-in. thickness constitutes the<br />

taper's rise. Butt the guide board<br />

blank against the stop and the<br />

shim and nail it to the sled. Mark<br />

the tapered edge and the direction<br />

of is slope. Then cut the taper<br />

(Photo 2).<br />

Assemble the jig (Photo 3). It<br />

should fit snugly over the cabi<strong>net</strong><br />

sides. Make sure the tapered guide<br />

boards angle outward from front to<br />

back. The distance between the<br />

guide boards at the front of the jig<br />

determines the narrow width of the<br />

dovetail socket. For example, to<br />

make a 5,28-in.-wide socket using a<br />

l,/2-in. dovetail bit, the distance<br />

between the faces would measure<br />

the diameter of your router's base<br />

plus 1,/8-in. This socketwould swell<br />

to 11,/1Gin. at the back of a 12-in.-<br />

wide workpiece. Tapered sockets<br />

(and dovetails) of this width are<br />

perfect for the 3,/4in.-thick stock<br />

shown here.<br />

Frc. ,A<br />

ROUTING JIG<br />

This jig consists of two<br />

parallel rails and two guide<br />

boards.The inside edge of each guide<br />

board tapers outward at the rate of 1/32-in' per<br />

12-in. length. On a 12-in.-wide board, this jig creates a<br />

socket that increases in width by 1/16-in' overall'<br />

I Fasten the jig's guide boards to a sled for tapering, using a block, a stop and a<br />

I shim for positioning. Buttthe sled to the stop and the block.Then tape on the<br />

shim. lt's thickness and location determine the taper's slope. Butt the guide board to<br />

the stoo and the shim.Then nail it to the sled'<br />

C)taper the skewed edge of each guide<br />

lboard. Holding the sled against the<br />

rip fence skews the guide board's back<br />

end toward the blade.The taper is very<br />

slight, so indicate the tapered edge and<br />

the taoer's direction.<br />

QAssemble the jig around the cabi<strong>net</strong><br />

Jside. Butt everything against a block<br />

to guarantee the jig goes together<br />

squarely and the guide board tapers run<br />

true. Spacers elevate the rails for fastening<br />

the guide boards.<br />

American Woodworker ocToBER zoot 67