AW #131.pdf - Karatunov.net

AW #131.pdf - Karatunov.net

AW #131.pdf - Karatunov.net

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Brush affietry<br />

GET GREAT RESULTS WITHOUT RUBBING OUT.<br />

aybe I'm crazy, but I like to<br />

brush polyurethane. I've<br />

built more than 50 dining<br />

room tables, and I've brush-finished every<br />

one, using a simple system that consistently<br />

provides great results.<br />

I'm not a purist. I use tools that you can get at<br />

any paint store and I don't rub out the final coat.<br />

My tabletop finishes look good and feel smooth.<br />

They're durable...and do-able.<br />

A tabletop requires multiple coats, of course, but each<br />

one is applied the same way. I use flat, satin or semi-gloss<br />

polyurethane, depending on the look I want and the<br />

wood. A lower sheen helps to disguise finish imperfections,<br />

but it can make dark woods such as walnut look a<br />

bit hazy.<br />

You can practice my methods by finishing the bottom of<br />

your tabletop. It should have at least one coat offinish any-<br />

\{?y, to stabilize the top for seasonal changes in humidity.<br />

Srr UP FoR Succrss<br />

I always sand with 280-grit paper between frnish<br />

coats, and I let the polyr.rrethane dry thoroughly before<br />

sanding. I wipe the top twice to remove the sanding<br />

dust, first with a slightly damp lint-free cloth, then with<br />

a fresh tack cloth.<br />

After final sanding, I vacuum the top thoroughly<br />

before moving it into my finishing area. I like to apply<br />

finishes early in the morning, when the air is still and<br />

airborne debris has had all night to settle.<br />

82 American Woodworker OCToBER 2oo7<br />

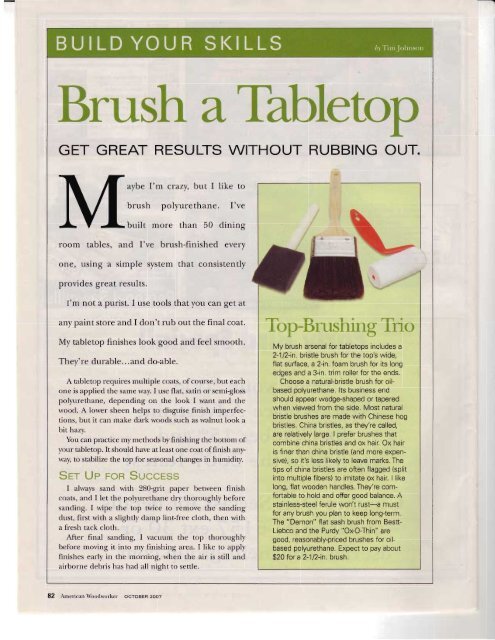

Ttp-Brushing Trio<br />

My brush arsenal for tabletops includes a<br />

2-112-in. bristle brush for the top's wide,<br />

flat surface, a 2-in. foam brush for its long<br />

edges and a 3-in. trim roller for the ends.<br />

Choose a natural-bristle brush for oilbased<br />

polvurethane. lts business end<br />

should appear wedge-shaped or tapered<br />

when viewed from the side. Most natural<br />

bristle brushes are made with Chinese hog<br />

bristles. China bristles, as they're called,<br />

are relatively large. I prefer brushes that<br />

combine china bristles and ox hair. Ox hair<br />

is finer than china bristle (and more exoensive),<br />

so it's less likely to leave marks. The<br />

tips of china bristles are often flagged (split<br />

into multiple fibers) to imitate ox hair. I like<br />

long, flat wooden handles. They're comfortable<br />

to hold and offer good balance. A<br />

stainless-steel ferule won't rust-a must<br />

for any brush you plan to keep long-term.<br />

The "Demon" flat sash brush from Bestt-<br />

Liebco and the Purdy "Ox-O-Thin" are<br />

good, reasonably-priced brushes for oilbased<br />

polyurethane. Expect to pay about<br />

$20 for a 2-112-in. brush.