petfood pro 4/2022

PetFood PRO is the international magazine for executives and specialists in the manufacture of food for domestic animals – the pet food industry. The magazine focuses on food and delicacies for dogs, cats and other small animals, ornamental birds and fish, as well as animals kept in terrariums. We publish feature articles, reports and announcements about new ingredients, technology, equipment and processes, packaging machinery and materials as well as marketing trends and developments. Readers are executives, product developers and specialists in the pet food industry, including process and packaging engineers. PetFood PRO will be published in English. Circulation is worldwide, with an emphasis on important growth markets.

PetFood PRO is the international magazine for executives and specialists in the manufacture of food for domestic animals – the pet food industry. The magazine focuses on food and delicacies for dogs, cats and other small animals, ornamental birds and fish, as well as animals kept in terrariums.

We publish feature articles, reports and announcements about new ingredients, technology, equipment and processes, packaging machinery and materials as well as marketing trends and developments. Readers are executives, product developers and specialists in the pet food industry, including process and packaging engineers. PetFood PRO will be published in English. Circulation is worldwide, with an emphasis on important growth markets.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INGREDIENTS<br />

Other biogenic amines mentioned before<br />

like cadaverine and putrescine are known<br />

to have an impact on the palatability of<br />

finished pet food, but this topic will be<br />

discussed deeper in the next section of<br />

this article.<br />

To avoid these consequences, it is important<br />

to maintain the freshness and quality of<br />

meat and meat <strong>pro</strong>ducts by avoiding<br />

microbiological growth, thus <strong>pro</strong>tecting<br />

materials as soon as possible from<br />

evisceration, transport, and <strong>pro</strong>cessing.<br />

Biogenic amines are heat resistant and<br />

acid resistant molecules, this means, that<br />

once they are formed in the fresh crude<br />

raw materials they will survive and stay<br />

present in the final <strong>pro</strong>duct <strong>pro</strong>duced with<br />

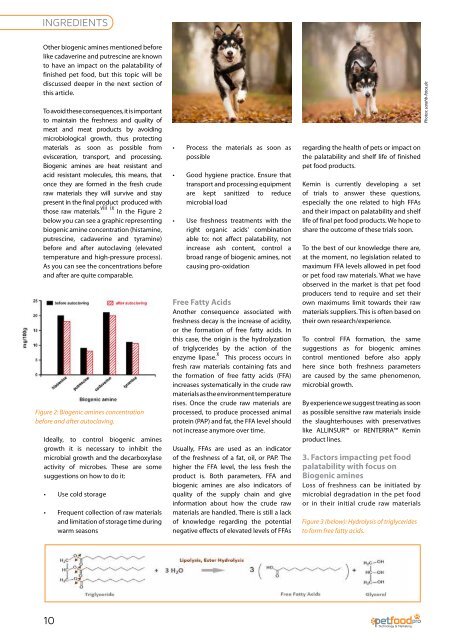

those raw materials. ⅷ ⅸ In the Figure 2<br />

below you can see a graphic representing<br />

biogenic amine concentration (histamine,<br />

putrescine, cadaverine and tyramine)<br />

before and after autoclaving (elevated<br />

temperature and high-pressure <strong>pro</strong>cess).<br />

As you can see the concentrations before<br />

and after are quite comparable.<br />

Figure 2: Biogenic amines concentration<br />

before and after autoclaving.<br />

Ideally, to control biogenic amines<br />

growth it is necessary to inhibit the<br />

microbial growth and the decarboxylase<br />

activity of microbes. These are some<br />

suggestions on how to do it:<br />

• Use cold storage<br />

• Frequent collection of raw materials<br />

and limitation of storage time during<br />

warm seasons<br />

• Process the materials as soon as<br />

possible<br />

• Good hygiene practice. Ensure that<br />

transport and <strong>pro</strong>cessing equipment<br />

are kept sanitized to reduce<br />

microbial load<br />

• Use freshness treatments with the<br />

right organic acids' combination<br />

able to: not affect palatability, not<br />

increase ash content, control a<br />

broad range of biogenic amines, not<br />

causing <strong>pro</strong>-oxidation<br />

Free Fatty Acids<br />

Another consequence associated with<br />

freshness decay is the increase of acidity,<br />

or the formation of free fatty acids. In<br />

this case, the origin is the hydrolyzation<br />

of triglycerides by the action of the<br />

enzyme lipase. ⅹ This <strong>pro</strong>cess occurs in<br />

fresh raw materials containing fats and<br />

the formation of free fatty acids (FFA)<br />

increases systematically in the crude raw<br />

materials as the environment temperature<br />

rises. Once the crude raw materials are<br />

<strong>pro</strong>cessed, to <strong>pro</strong>duce <strong>pro</strong>cessed animal<br />

<strong>pro</strong>tein (PAP) and fat, the FFA level should<br />

not increase anymore over time.<br />

Usually, FFAs are used as an indicator<br />

of the freshness of a fat, oil, or PAP. The<br />

higher the FFA level, the less fresh the<br />

<strong>pro</strong>duct is. Both parameters, FFA and<br />

biogenic amines are also indicators of<br />

quality of the supply chain and give<br />

information about how the crude raw<br />

materials are handled. There is still a lack<br />

of knowledge regarding the potential<br />

negative effects of elevated levels of FFAs<br />

regarding the health of pets or impact on<br />

the palatability and shelf life of finished<br />

pet food <strong>pro</strong>ducts.<br />

Kemin is currently developing a set<br />

of trials to answer these questions,<br />

especially the one related to high FFAs<br />

and their impact on palatability and shelf<br />

life of final pet food <strong>pro</strong>ducts. We hope to<br />

share the outcome of these trials soon.<br />

To the best of our knowledge there are,<br />

at the moment, no legislation related to<br />

maximum FFA levels allowed in pet food<br />

or pet food raw materials. What we have<br />

observed in the market is that pet food<br />

<strong>pro</strong>ducers tend to require and set their<br />

own maximums limit towards their raw<br />

materials suppliers. This is often based on<br />

their own research/experience.<br />

To control FFA formation, the same<br />

suggestions as for biogenic amines<br />

control mentioned before also apply<br />

here since both freshness parameters<br />

are caused by the same phenomenon,<br />

microbial growth.<br />

By experience we suggest treating as soon<br />

as possible sensitive raw materials inside<br />

the slaughterhouses with preservatives<br />

like ALLINSUR or RENTERRA Kemin<br />

<strong>pro</strong>duct lines.<br />

3. Factors impacting pet food<br />

palatability with focus on<br />

Biogenic amines<br />

Loss of freshness can be initiated by<br />

microbial degradation in the pet food<br />

or in their initial crude raw materials<br />

Figure 3 (below): Hydrolysis of triglycerides<br />

to form free fatty acids.<br />

Photos: sarahb-fotos.de<br />

10<br />

Technology & Marketing