- Page 2: TEXTILE COMPOSITES AND INFLATABLE S

- Page 6: Textile Composites and Inflatable S

- Page 10: Table of Contents Preface .........

- Page 14: PREFACE The objective of this book

- Page 18: 2 Rosemarie Wagner can be evaluated

- Page 22: 4 Rosemarie Wagner The tension forc

- Page 28: Dividing the surface by geodesic li

- Page 32: E1111 U11 U U22 U On theDesign Proc

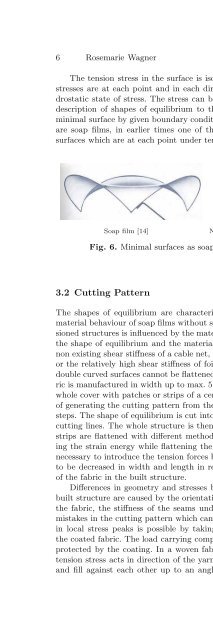

- Page 36: Minimal surface (without orientatio

- Page 40: with (4), (5) and (6) in (2) follow

- Page 44: On theDesign Process of Tensile Str

- Page 48: Systems for Lightweight Structure D

- Page 52: Systems for Lightweight Structure D

- Page 56: Systems for Lightweight Structure D

- Page 60: Systems for Lightweight Structure D

- Page 64: 4 Design System Architecture 4.1 De

- Page 68: Systems for Lightweight Structure D

- Page 72: Recent Developments in the Analytic

- Page 76:

Recent Developments in the Analytic

- Page 80:

Recent Developments in the Analytic

- Page 84:

Recent Developments in the Analytic

- Page 88:

Recent Developments in the Analytic

- Page 92:

Recent Developments in the Analytic

- Page 96:

Recent Developments in the Analytic

- Page 100:

Recent Developments in the Analytic

- Page 104:

Recent Developments in the Analytic

- Page 108:

48 Robert L. Taylor, Eugenio Oñate

- Page 112:

50 Robert L. Taylor, Eugenio Oñate

- Page 116:

52 Robert L. Taylor, Eugenio Oñate

- Page 120:

54 Robert L. Taylor, Eugenio Oñate

- Page 124:

56 Robert L. Taylor, Eugenio Oñate

- Page 128:

58 Robert L. Taylor, Eugenio Oñate

- Page 132:

60 Robert L. Taylor, Eugenio Oñate

- Page 136:

62 Robert L. Taylor, Eugenio Oñate

- Page 140:

64 Robert L. Taylor, Eugenio Oñate

- Page 144:

66 Robert L. Taylor, Eugenio Oñate

- Page 148:

68 Robert L. Taylor, Eugenio Oñate

- Page 152:

70 Fernando Flores and Eugenio Oña

- Page 156:

72 Fernando Flores and Eugenio Oña

- Page 160:

74 Fernando Flores and Eugenio Oña

- Page 164:

76 Fernando Flores and Eugenio Oña

- Page 168:

78 Fernando Flores and Eugenio Oña

- Page 172:

80 Fernando Flores and Eugenio Oña

- Page 176:

82 Fernando Flores and Eugenio Oña

- Page 180:

84 Fernando Flores and Eugenio Oña

- Page 184:

86 Fernando Flores and Eugenio Oña

- Page 188:

88 Fernando Flores and Eugenio Oña

- Page 192:

90 Riccardo Rossi, Vitaliani Renato

- Page 196:

92 Riccardo Rossi, Vitaliani Renato

- Page 200:

94 Riccardo Rossi, Vitaliani Renato

- Page 204:

96 Riccardo Rossi, Vitaliani Renato

- Page 208:

98 Riccardo Rossi, Vitaliani Renato

- Page 212:

100 Riccardo Rossi, Vitaliani Renat

- Page 216:

102 Riccardo Rossi, Vitaliani Renat

- Page 220:

104 Riccardo Rossi, Vitaliani Renat

- Page 224:

106 Riccardo Rossi, Vitaliani Renat

- Page 228:

108 Riccardo Rossi, Vitaliani Renat

- Page 232:

110 Y.W. Wong and S. Pellegrino Thi

- Page 236:

112 Y.W. Wong and S. Pellegrino ana

- Page 240:

114 Y.W. Wong and S. Pellegrino and

- Page 244:

116 Y.W. Wong and S. Pellegrino Sub

- Page 248:

118 Y.W. Wong and S. Pellegrino TIE

- Page 252:

120 Y.W. Wong and S. Pellegrino w (

- Page 256:

122 Y.W. Wong and S. Pellegrino 8.

- Page 260:

124 Antonio J. Gil prestressed memb

- Page 264:

126 Antonio J. Gil e3 R0 e2 e1 X pr

- Page 268:

128 Antonio J. Gil P ∗relat P ji,

- Page 272:

130 Antonio J. Gil both prestressed

- Page 276:

132 Antonio J. Gil where K matIJ an

- Page 280:

134 Antonio J. Gil 4 Numerical Exam

- Page 284:

136 Antonio J. Gil Total Potential

- Page 288:

138 Antonio J. Gil Total Potential

- Page 292:

140 Antonio J. Gil element in the i

- Page 296:

142 Antonio J. Gil 14. B. Wu, X. Du

- Page 300:

144 Kai-Uwe Bletzinger, Roland Wüc

- Page 304:

146 Kai-Uwe Bletzinger, Roland Wüc

- Page 308:

148 Kai-Uwe Bletzinger, Roland Wüc

- Page 312:

150 Kai-Uwe Bletzinger, Roland Wüc

- Page 316:

Efficient Finite Element Modelling

- Page 320:

FE Modelling and Simulation of Gas

- Page 324:

FE Modelling and Simulation of Gas

- Page 328:

FE Modelling and Simulation of Gas

- Page 332:

FE Modelling and Simulation of Gas

- Page 336:

FE Modelling and Simulation of Gasa

- Page 340:

FE Modelling and Simulation of Gas

- Page 344:

FE Modelling and Simulation of Gas

- Page 348:

FE Modelling and Simulation of Gas

- Page 352:

FE Modelling and Simulation of Gas

- Page 356:

Widespan Membrane Roof Structures:

- Page 360:

Widespan Membrane Roof Structures 1

- Page 364:

Widespan Membrane Roof Structures 1

- Page 368:

Widespan Membrane Roof Structures 1

- Page 372:

Widespan Membrane Roof Structures 1

- Page 376:

Widespan Membrane Roof Structures 1

- Page 380:

Widespan Membrane Roof Structures 1

- Page 384:

3 Reliability Analysis Widespan Mem

- Page 388:

Widespan Membrane Roof Structures 1

- Page 392:

4 Monitoring Widespan Membrane Roof

- Page 396:

Widespan Membrane Roof Structures 1

- Page 400:

Fabric Membranes Cutting Pattern Be

- Page 404:

2.2 Geometrical Issues Fabric Membr

- Page 408:

3 Cutting Shapes Determination 3.1

- Page 412:

3.2 Stress Composition Method Fabri

- Page 416:

Fabric Membranes Cutting Pattern 20

- Page 420:

Fabric Membranes Cutting Pattern 20

- Page 424:

Fabric Membranes Cutting Pattern 20

- Page 428:

Fabric Membranes Cutting Pattern 20

- Page 432:

curvatures are hence: Fabric Membra

- Page 436:

Inflated Membrane Structures on the

- Page 440:

Inflated Membrane Structures on the

- Page 444:

Inflated Membrane Structures on the

- Page 448:

Inflated Membrane Structures on the

- Page 452:

Post-Tensioned Modular Inflated Str

- Page 456:

Post-Tensioned Modular Inflated Str

- Page 460:

Post-Tensioned Modular Inflated Str

- Page 464:

Post-Tensioned Modular Inflated Str

- Page 468:

5 Technological Concepts 5.1 Air-In

- Page 472:

Post-Tensioned Modular Inflated Str

- Page 476:

6 Examples of Application Post-Tens

- Page 480:

Post-Tensioned Modular Inflated Str

- Page 484:

Post-Tensioned Modular Inflated Str

- Page 488:

7Conclusive Remarks Post-Tensioned

- Page 492:

242 Javier Marcipar, Eugenio Oñate

- Page 496:

244 Javier Marcipar, Eugenio Oñate

- Page 500:

246 Javier Marcipar, Eugenio Oñate

- Page 504:

248 Javier Marcipar, Eugenio Oñate

- Page 508:

250 Javier Marcipar, Eugenio Oñate

- Page 512:

252 Javier Marcipar, Eugenio Oñate

- Page 516:

254 Javier Marcipar, Eugenio Oñate

- Page 520:

256 Javier Marcipar, Eugenio Oñate

- Page 524:

Recent Advances in the Rigidization

- Page 528:

Recent Advances in the Rigidization

- Page 532:

Recent Advances in the Rigidization

- Page 536:

Recent Advances in the Rigidization

- Page 540:

Recent Advances in the Rigidization

- Page 544:

Recent Advances in the Rigidization

- Page 548:

Technology Evaluation Recent Advanc

- Page 552:

Recent Advances in the Rigidization

- Page 556:

Absorbance 0,5 0,4 0,3 0,2 0,1 Rece

- Page 560:

Recent Advances in the Rigidization

- Page 564:

Recent Advances in the Rigidization

- Page 568:

Recent Advances in the Rigidization

- Page 572:

Recent Advances in the Rigidization

- Page 576:

286 Edgar Stach Key words: Form-opt

- Page 580:

288 Edgar Stach 3 2-D Bubble Cluste

- Page 584:

290 Edgar Stach Fig. 15. Closest pa

- Page 588:

292 Edgar Stach Fig. 17. Various ge

- Page 592:

294 Edgar Stach Fig. 20. SKO method

- Page 596:

296 Edgar Stach Fig. 26. Fig. 27. D

- Page 600:

298 Edgar Stach Fullerene 5 The sma

- Page 604:

300 Edgar Stach To take Fuller’s

- Page 608:

302 Edgar Stach Figs. 47-49. The me

- Page 612:

Making Blobs with a Textile Mould A

- Page 616:

Making Blobs with aTextile Mould 30

- Page 620:

Making Blobs with aTextile Mould 30

- Page 624:

Fig. 11. Bending for power, a pole

- Page 628:

Making Blobs with aTextile Mould 31

- Page 632:

Making Blobs with aTextile Mould 31

- Page 636:

Fig. 30. To create a declining faca

- Page 640:

Making Blobs with aTextile Mould 31

- Page 644:

7Conclusion Making Blobs with aText