2023_11_Sustainable Truck&Van

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MAGAZINE<br />

VADO E TORNO EDIZIONI<br />

www.vadoetorno.com<br />

www.vadoetornoweb.com<br />

www.sustainabletruckvan.com<br />

VADOETORNO SUPPLEMENT<br />

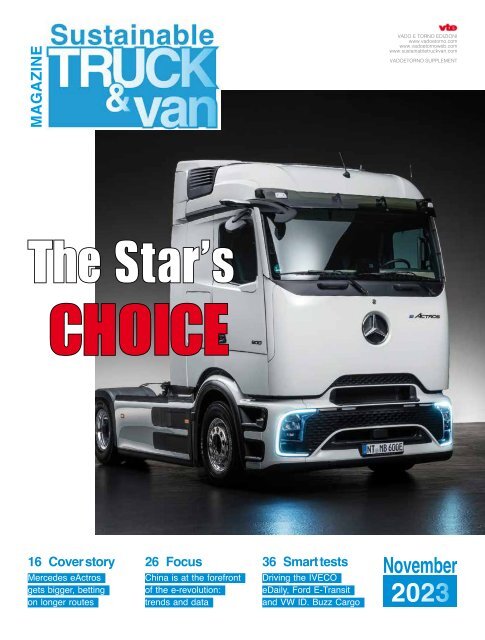

The Star's<br />

CHOICE<br />

16 Cover story<br />

Mercedes eActros<br />

gets bigger, betting<br />

on longer routes<br />

26 Focus<br />

China is at the forefront<br />

of the e-revolution:<br />

trends and data<br />

36 Smart tests<br />

Driving the IVECO<br />

eDaily, Ford E-Transit<br />

and VW ID. Buzz Cargo<br />

November<br />

<strong>2023</strong>

sustainabletruckvan.com<br />

CONTENTS<br />

NOVEMBER <strong>2023</strong><br />

Awards<br />

10 SUSTAINABLE TRUCK OF THE YEAR<br />

The challenge of emissions reduction<br />

26<br />

Face-to-face<br />

12 THE PLACE TO BE<br />

Solutrans MD, Guillaume Schaeffer, speaking<br />

14 FAR-SIGHTED VISION<br />

Interview with Andreas Follér (TRATON)<br />

ENTER THE<br />

FOLLOW SUSTAINABLE TRUCK&VAN ON:<br />

Cover Story<br />

16 THE NEW FLAGSHIP<br />

Mercedes-Benz eActros 600<br />

Previews<br />

20 ELECTRIC AWARENESS<br />

Renault Trafic E-Tech<br />

24 THE BRAND-NEW ADDITION<br />

Renault Trucks introducing C and T e-models<br />

Focus<br />

26 WATCH OUT THE DRAGON<br />

China at the forefront of the electric revolution<br />

Innovations<br />

30 THE SUN IS SHINING<br />

Scania testing a hybrid truck with solar panels<br />

32 CHALLENGE ACCEPTED<br />

Volvo Trucks: new batteries, enhanced production<br />

34 TRANSITION MADE EASIER<br />

Quantron split between BEVs and FCEVs<br />

30<br />

Smart Tests<br />

36 WALKING IN MY FOOTSTEPS<br />

IVECO eDaily 38S 14EV<br />

WELCOME TO AN<br />

ELECTRIC TRANSPORT<br />

REFRIGERATION WORLD<br />

AT SOLUTRANS<br />

Join us at<br />

SOLUTRANS<br />

LYON, FRANCE<br />

NOVEMBER<br />

21-25 <strong>2023</strong><br />

This year at Solutrans, you’ll find solutions,<br />

not challenges at the Thermo King booth.<br />

To help your fleet reach its sustainability targets,<br />

we bring together an electric lineup of refrigeration<br />

units and a host of performance-enhancing solutions.<br />

Discover how you can make a difference tomorrow,<br />

starting today.<br />

HALL 4<br />

BOOTH F 086<br />

44<br />

40 NEVER ENDING STORIES<br />

Ford E-Transit paves the way<br />

44 THE EYE CATCHER<br />

Volkswagen ID. Buzz Cargo<br />

Columns<br />

6 At a glance 48 Techno 50 Infrastructure<br />

Who we are. The journey continues<br />

The path that led us to the first paper issue of the<br />

magazine, available online in its digital version and<br />

distributed at the major international exhibitions p.4<br />

3

NEWS WHO WE ARE<br />

A FURTHER STEP, AFTER TWO YEARS AND A HALF OF WEB ACTIVITIES<br />

The journey continues<br />

THE PATH THAT LED US TO THE FIRST PAPER ISSUE OF STV MAGAZINE<br />

Our publishing company,<br />

Vado e Torno Edizioni,<br />

embraced the concept of<br />

sustainability quite a long time<br />

ago. In 2015, when it was not<br />

yet as popular and widespread<br />

as it is today the Sustainability<br />

Index was created, with the<br />

aim of making measurable not<br />

only the ecological impact of<br />

the vehicles we were testing<br />

in our Supertests, but also<br />

their features in terms of<br />

innovation, safety, comfort,<br />

recyclability of components,<br />

to determine its social impact.<br />

Another milestone in the history<br />

of our publishing house was<br />

the creation, in 2016, of the<br />

<strong>Sustainable</strong> Truck of the Year<br />

Awards (please have a look at<br />

page 10) in the three categories<br />

Tractor, Distribution, and<br />

<strong>Van</strong>. The Awards are assigned yearly to the vehicles that most stand<br />

out for innovation and sustainability. In the wake of these experiences,<br />

and not only in the freight sector – it is also worth to mention the<br />

successful <strong>Sustainable</strong> Bus platform – the initiatives have continued<br />

over the years. In June 2021, the <strong>Sustainable</strong> Truck&<strong>Van</strong> website<br />

made its online debut.<br />

Riding the wave of an energy transition that is still at the very early<br />

stage, at least for trucks, our platform has established itself as a point<br />

of reference in the debate on the new generation of zero-emission<br />

vehicles worldwide, focusing its attention not only on technology –<br />

which is crucial in our vision – but also, for instance, dealing with<br />

the sector regulations, as well as market trends on a global scale.<br />

<strong>Sustainable</strong> Truck&<strong>Van</strong> Magazine, freely available online in its<br />

digital version and distributed at the major international exhibitions,<br />

starting from Solutrans in Lyon, is intended to be a further step in a<br />

sustainable journey that will always see us acting as frontrunners.<br />

SUBSCRIBE<br />

TRUCK CLEAN<br />

Ready to switch to H2?<br />

Heavy-duty fleet managers agree: the total cost of ownership (TCO) for hydrogenfueled<br />

trucks will soon match diesel vehicles. To put H2 trucks on the roads at scale,<br />

manufacturers need suppliers with knowhow and experience. That’s where we come<br />

in. Our on-board fueling systems for compressed H2 arrive complete with<br />

type-3 or -4 cylinders, gas street components, and frames. Now you can drop fleet<br />

emissions while maintaining the same maintenance, fueling, and route schedules as<br />

with diesel trucks.<br />

SCAN THE QR CODE AND JOIN<br />

OUR COMMUNITY OF ABOUT<br />

20,000 PROFESSIONALS<br />

WORLDWIDE<br />

SWITCH TO H2 TODAY:<br />

www.worthingtonindustries.eu/markets/mobility<br />

at-customerservice@worthingtonindustries.com<br />

+43 7485 606 0<br />

4

AT A GLANCE<br />

VOLTA TRUCKS FILES FOR BANKRUPTCY IN SWEDEN<br />

A sudden, brutal awakening<br />

ONLY NEW POSSIBLE INVESTORS MAY SAVE THE COMPANY<br />

FORD TRUCKS AND QUANTRON TO COOPERATE UNDER NEWLY-SIGNED LOI<br />

Hydrogen trucks, two is better than one<br />

FORD TRUCKS WILL BE ALSO WORKING WITH CANADIAN BALLARD<br />

In the middle of October, Swedish e-truck manufacturer Volta<br />

Trucks officially opened bankruptcy proceedings. The<br />

decision was made reluctantly by the Board that seemed<br />

to have got into gear and was preparing to start mass<br />

production of its 16-ton vehicle we tested not more than<br />

a year ago.<br />

It all started, according to official communications, from<br />

the crisis involving U.S. battery supplier Proterra, which<br />

in turn had to open the same bankruptcy proceedings<br />

in recent months. The stop in supplies had an obviously<br />

unsustainable impact on Volta Trucks and its investors,<br />

who were crucial in the early launch phase of the Swedish<br />

venture. The sad new was immediately confirmed on<br />

social media via messages posted by the company<br />

management and workers. Volta Trucks had begun smallscale<br />

production of its 16-ton electric truck, the Volta Zero,<br />

in Steyr, Austria. Other smaller variants-specifically, 7.5-<br />

and 12-ton ones-were planned for the next few years. Thus,<br />

the adventure of a company that promised to revolutionize<br />

electric mobility for urban distribution comes to an end in<br />

a way that was hardly predictable, at least in terms of timing.<br />

Is it the end of it all? Perhaps. We do know, however, that<br />

the management of the Swedish company, starting with cofounders<br />

Carl-Magnus Norden and Kjell Waloen, want to try<br />

at all costs not to dissipate the knowledge and development<br />

capital accumulated so far, including the trucks that have<br />

already been made and now lay unused in warehouses.<br />

The road to a possible happy ending is only one: being able to find<br />

new investors willing to trust the idea, even more than the people.<br />

The game is not entirely closed, in short, although the road is as<br />

uphill as ever. Let’s remind that nearly 850 people worked at Volta<br />

Trucks all over Europe. Hubs had already been inaugurated in Paris,<br />

France, and London, UK, with Germany and Italy as next targets.<br />

Volta Trucks was supposed to exhibit at Solutrans, in Lyon.<br />

HYDROGEN TRUCK PLATFORM<br />

Innovative UK-based hydrogenpowered<br />

vehicle manufacturer<br />

HVS (Hydrogen Vehicle<br />

Systems) has unveiled its<br />

modular platform for heavyduty<br />

vehicles that provides a<br />

hydrogen fuel cell powertrain<br />

with medium and high-power<br />

e-axles, up to three hydrogen<br />

tanks and two power outputs.<br />

The company’s tractor unit will<br />

be available with two different<br />

types of e-axle and with up to<br />

three hydrogen tanks, depending<br />

on the customer’s range<br />

requirements. In addition, the<br />

hydrogen fuel cell powertrain can<br />

be specified with two different<br />

power outputs depending on the<br />

customer’s payload and mission<br />

requirements.<br />

.The 16-ton Volta Zero electric truck.<br />

First charging hub<br />

Milence, the joint venture shared by Daimler<br />

Truck, TRATON and Volvo, will open its very<br />

first charging hub in the Netherlands by the end<br />

of November. The announcement was made<br />

via a LinkedIn message on the official page.<br />

Why Venlo? Because it’s “one of Europe’s<br />

leading logistics hubs and ideally positioned for<br />

international trade”, as stated by Milence.<br />

With the new Milence Charging Hub, Truck<br />

Parking Venlo will be the first secure truck<br />

parking facility in the Netherlands to offer a<br />

charging solution for electric trucks. Milence<br />

has denied the presence of MCS (Megawatt<br />

Charging Systems) in the Venlo facility. Not yet,<br />

they said, even though MCS will be added in<br />

the future, when they’re truly available in the<br />

market. The first charging hub will be equipped<br />

with 2 chargers and have 4 charging bays when<br />

it opens at the end of November. Additional<br />

charging bays are planned for 2024.<br />

Truck manufacturers Quantron and Ford Trucks have recently<br />

signed a letter of intent (LoI). Within this strategic cooperation,<br />

“the Quantron Inside technology effective range, innovative e-axle,<br />

customized high-power battery, fuel cell and tank integration,<br />

unparalleled energy-management and optimized aerodynamics for<br />

maximized efficiency will be evaluated for integration into Ford<br />

Trucks’ vehicles, thus enabling emission-free transport solutions.<br />

The focus of the collaboration lies in hydrogen fuel cell-powered<br />

heavy-duty trucks”, as stated by the partners.<br />

It is no coincidence that a couple of months ago Ford Trucks<br />

announced a partnership with Ballard for fuel cell development<br />

and supply. Under this agreement, the 120 kW FCmove-XD fuel<br />

cell engines are planned to be integrated into Ford Trucks’ F-MAX<br />

44-ton long-haul tractor truck that Ford Trucks plans to build and<br />

assemble in Turkey not before 2025. Ballard is among the investors<br />

of the entire Quantron project, in addition to the supplier of fuel cell<br />

stacks installed on Quantron FCEV trucks.<br />

Back to the agreement reached between Ford Trucks and Quantron,<br />

through the first phase of collaboration, Quantron will ensure a<br />

seamless adaptation of Ford’s advanced trucks which will be built in<br />

compliance with the new security regulations.<br />

“Partnering with a renowned vehicle manufacturer like Ford Trucks<br />

enhances Quantron’s position as an innovation leader in the field of<br />

sustainable transport solutions and being a partner for established<br />

Commercial Vehicle OEMs”, stated Michael Perschke, CEO of<br />

Quantron AG.<br />

“We are excited to have Quantron’s support as a seasoned partner<br />

in our endeavor to offer a fuel-cell electric heavy-duty truck to our<br />

customers. This collaboration promises to yield substantial value in<br />

the times ahead. Ford Trucks is committed to investing in innovative<br />

technologies that will shape the future of the heavy commercial<br />

vehicle industry while aligning with our sustainability goals. Our<br />

primary focus is on electrification, closely followed by advancements<br />

in hydrogen technology”, added Ford Trucks leader Emrah Duman.<br />

FURTHER RESHAPING<br />

Electric van manufacturer Arrival<br />

has announced the intention fo<br />

cut workforce by further 25 per<br />

cent. The UK-based company<br />

has been quite in trouble for<br />

some months and was forced to<br />

deeply change its own business.<br />

Arrival won’t be building neither<br />

electric cars nor electric buses<br />

anymore and had announced<br />

the intention to focus only on the<br />

North American<br />

market.<br />

Following the<br />

workforce<br />

reduction action happened<br />

in January, the overall Arrival<br />

workforce counted more or<br />

less 800 people. Some months<br />

later, the company managed to<br />

get further cash injection from<br />

Westwood Capital. Igor Torgov<br />

is the new company CEO. He<br />

replaced interim CEO, Peter<br />

Cuneo, in turn appointed in<br />

November, 2022, when the<br />

company’s<br />

founder Denis<br />

Sverdlov<br />

stepped back.<br />

Güven Öyzurt, CEO Ford Otosan, and Andreas<br />

Haller, founder and Executive Chairman of<br />

Quantron AG, signing the letter of intent for the<br />

joint development of hydrogen trucks.<br />

Battery Experts Forum<br />

Europe’s largest and most established<br />

networking platform for the global battery<br />

community, Battery Experts Forum, was held<br />

in Darmstadt from November 7 to 9. The<br />

international event has reached this year its 18th<br />

edition: it’s a top-class scientific conference with<br />

accompanying trade exhibition along the entire<br />

value chain of battery technology.<br />

The event’s multifaceted program consisted of<br />

tutorials, keynotes and<br />

technical presentations<br />

with a scientific-innovative<br />

character and focuses<br />

on the main topics of the<br />

global market, e-mobility,<br />

battery production, cell<br />

design, battery safety,<br />

battery management<br />

systems and testing<br />

methods, and circular economy.<br />

The event, held in English, is particularly known<br />

for its intensive networking opportunities. The<br />

multinational attendance includes mainly buyers,<br />

R&D specialists and top managers from a wide<br />

range of industries such as medical, garden and<br />

power tools, e-mobility and energy storage, who<br />

are keen to learn and exchange information on<br />

the latest developments in battery technology.<br />

6<br />

7

AT A GLANCE<br />

THE FIRST IVECO-BRANDED ZERO EMISSION TRUCKS<br />

Every end is a new beginning<br />

THE NEW IVECO TRUCKS COME FROM THE END OF THE JV WITH NIKOLA<br />

MAN STARTED SELLING ITS VERY FIRST ELECTRIC TRUCK MODELS<br />

E-truck buyers awaited<br />

THE FIRST 200 UNITS SCHEDULED TO ROLL OUT NEXT YEAR<br />

Following the end of the joint venture with Nikola and the<br />

creation of the EVCO brand, IVECO introduced the heavy-duty<br />

battery-electric and fuel cell trucks marketed under its own brand.<br />

Of course, the trucks are a re-branding of the zero-emission models<br />

developed in the latest years in cooperation with Nikola.<br />

More into details, the IVECO HD BEV has a range of up to 500<br />

km. It features a total battery capacity of 738 kWh (9 packs) with<br />

charging power up to 350 kW, which enables hub-to-hub delivery<br />

missions, a wide range of regional applications, and even missions<br />

requiring extended mileage with charging opportunity during<br />

mandated driver stops. The Artic 4×2 configuration will be the first<br />

to enter the European market in the last quarter of <strong>2023</strong>.<br />

On the other hand, the IVECO HD FCEV boasts a range of up to 800<br />

km. With a fast-refuelling time of under 20 minutes, it is conceived<br />

for the long-haul mission in heavy commercial transportation. It<br />

can accommodate 70 kg of H2 usable energy at 700-bar pressure.<br />

According to the plans previously made public by IVECO, the first<br />

units of the IVECO-branded FCEVs will be delivered by the end of<br />

<strong>2023</strong>, namely in France, Switzerland and Germany, as planned in<br />

the H2Haul European project co-financed by the Clean Hydrogen<br />

Partnership aimed at accelerating the deployment of hydrogen<br />

solutions in the commercial transport industry and enabling the<br />

large-scale fuel cell truck market in the coming years. The IVECO<br />

HD BEV and FCEV feature an electric axle co-designed and<br />

produced by FPT Industrial, IVECO’s sister brand within Iveco<br />

Group specialized in powertrain. Fuel cell technology and key<br />

components are manufactured by Bosch.<br />

8<br />

E-VANS TOGETHER<br />

Two major groups (actually, three) join forces for<br />

electric vans of the future. Volvo and Renault,<br />

with the addition of French logistics group<br />

CMA CGM, today announced plans to form<br />

a new entity with the aim to design a shared<br />

architecture that will be the basis for future<br />

electric vans.<br />

The new company, which will be based in<br />

France, is expected to be launched in 2024, with<br />

production scheduled to start in 2026, according<br />

to the partners’ plans. The vehicles will be built<br />

on “on a new fully electric LCV skateboard<br />

platform that will offer high modularity for different<br />

body types at low cost and breakthrough on<br />

safety requirements”.<br />

Dragged into court<br />

British e-truck manufacturer Tevva is about to file a<br />

lawsuit against ElectraMeccanica (EMV), following<br />

the missed merger agreement between the two<br />

companies, which had been announced at the end<br />

of August, this year. In October, e-mobility specialist<br />

ElectraMeccanica announced the intention to step<br />

back. This was the beginning of quite a harsh<br />

communication battle, which will end in court.<br />

“The Tevva team was deeply disappointed by this<br />

abrupt decision and had no opportunity to respond<br />

to ElectraMeccanica’s claims before they went<br />

public”, stated the British manufacturer of zero<br />

emission trucks.<br />

At the same<br />

time, the lawsuit<br />

is not supposed<br />

to change the<br />

company’s<br />

operations and<br />

targets, at the<br />

moment.<br />

At the end of October, MAN Truck & Bus has officially launched<br />

sales of the eTruck, the first heavy-duty electric truck in the Lion’s<br />

history. According to the manufacturer’s statement, at least 600<br />

order inquiries have already been received, with the first 200 units<br />

scheduled to roll out to selected customers as early as 2024.<br />

With the eMobility Center, MAN laid the foundation for the<br />

development of the new MAN eTGX and MAN eTGS highvolume<br />

electric trucks at its Munich plant around two years ago<br />

and invested heavily in preparations for mixed production of diesel<br />

and electric trucks. 50 prototypes have since been built, and around<br />

4,000 employees from production and sales have been trained for<br />

the switch to electric mobility. At MAN’s Nuremberg site, MAN is<br />

investing around €100 million in setting up battery production.<br />

Developed by MAN specifically for use in commercial vehicles,<br />

batteries will be mass-produced at the Nuremberg plant from 2025.<br />

With their NMC cell chemistry and specially developed temperature<br />

management, the battery packs offer high energy density with a<br />

compact design, long service life and fast charging – even with low<br />

residual battery charge and low outside temperatures.<br />

Focus on hydrogen<br />

SUSTAINABLE MOBILITY WITH NO BARRIERS<br />

Tackling the big issue of sustainable<br />

mobility must contemplate a distinct<br />

change in mindset. Perhaps the<br />

main message we take home after<br />

participating in the second edition of<br />

the Global Mobility Call in Madrid is as<br />

much intangible as it is perspective.<br />

The Spanish exhibition, born on the<br />

initiative of Smobhub, an aggregator<br />

of companies, and actors of<br />

tomorrow’s mobility, and with the active<br />

collaboration of Ifema Madrid, is in fact<br />

an attempt to “bring together under<br />

one roof all the key stakeholders and<br />

actors in the ecosystem of sustainable<br />

mobility,” as Juan José Lillo, co-founder<br />

of Smobhub, creator and curator of<br />

the event, told us. Although focused<br />

on the Spanish market, Global Mobility<br />

Via the HYLA brand, Nikola has officially launched its<br />

hydrogen fuel cell truck with a dedicated ceremony<br />

in Coolidge, Arizona, where the manufacturer has<br />

its HQs. Nikola’s hydrogen fuel cell electric truck<br />

features a range of up to 500 miles (800 km) and an<br />

estimated fueling time as low as 20 minutes.<br />

According to the U.S.-based manufacturer, Nikola<br />

and its dealers have received 223 non-binding orders<br />

for its hydrogen fuel cell electric trucks from 23<br />

customers.<br />

Notable fleet operators such as J.B. Hunt, AJR<br />

Trucking, Biagi Bros. and TTSI, are among the<br />

growing list of customers committing to the future of<br />

sustainable trucking. It’s quite useful to remind that<br />

since the end of the joint venture with Iveco, Nikola’s<br />

truck business now focuses only on the North<br />

American market and mainly on hydrogen-powered<br />

trucks.<br />

Call is evidently trying to become<br />

more international, and with some<br />

appreciable results, gathering 500<br />

speakers, more than 100 exhibitors and<br />

over 8,000 professionals, 60 per cent of<br />

which in apex managerial position.<br />

The second edition of the<br />

Global Mobility Call was<br />

held in Madrid from 24<br />

to 26 October. The next<br />

edition is scheduled in<br />

November 2024.<br />

9

AWARDS<br />

STY 2024<br />

THE CHALLENGE<br />

Visit the STY website<br />

OF EMISSIONS<br />

REDUCTION<br />

The <strong>Sustainable</strong> Truck of the Year Awards are asseigned yearly by<br />

a professional jury in three categories: Tractor, Distribution, <strong>Van</strong>.<br />

The nominees (three per each category) will be announced at the<br />

beginning of 2024. The awarding ceremony of the STY 2024 is<br />

scheduled in Spring, next year.<br />

The EU Energy Council held on October<br />

17 confirmed the CO2 emission reduction<br />

targets: -15% in 2025 (already planned),<br />

-45% from 2030 (previously it was -30%),<br />

-65% from 2035, and -90% percent from 2040,<br />

compared to 2019. At the same time postponing<br />

the possibility of including biofuels as ‘eligible<br />

in the future’ until 2027. Such decisions are<br />

being made while one of the new players in ZE<br />

transportation, namely Volta Trucks, has just<br />

filed for bankruptcy, Arrival (van) drastically<br />

reduces plans, Iveco’s former partner Nikola is<br />

in trouble, and Tesla’s long-awaited Semi truck<br />

remains quite controversial. And while biofuels,<br />

if one adopts the ‘well to wheel’ method<br />

of calculating CO2 emissions, thus considering<br />

the entire production cycle, show that they can<br />

cut CO2 by 90 percent.<br />

In such a context, the <strong>Sustainable</strong> Truck of the<br />

Year Awards aim to reward vehicles that meet<br />

the concept of sustainability declined on several<br />

fronts: from emissions to safety, up to social<br />

and economic impact. Thus, if for the <strong>Van</strong> and<br />

Distribution categories the transition to electric<br />

seems desirable, as well as possible and somehow<br />

economically sustainable, it’s far more<br />

challenging when it comes to road tractors.<br />

The Award<br />

As the first and<br />

only European<br />

award that<br />

acknowledges<br />

sustainability in<br />

the field of trucks<br />

and vans, the STY<br />

rewards yearly<br />

three vehicles<br />

that stands out<br />

within several<br />

aspects such as<br />

safety; comfort;<br />

recyclability of<br />

components;<br />

connectivity; brand<br />

commitment on<br />

sustainability.<br />

10 <strong>11</strong>

FACE-TO-FACE<br />

SOLUTRANS’ MANAGING DIRECTOR SPEAKING<br />

THE PLACE TO BE<br />

Solutrans’ new Managing<br />

Director, Guillaume<br />

Schaeffer, whom<br />

we met in Milan, seemed to<br />

be quite happy about how the<br />

event has been welcomed.<br />

Nearly all the European truck<br />

manufacturers will be showcasing<br />

their products and<br />

solutions, except for Volvo<br />

Trucks. And all the Stellantis<br />

brands will be back in Lyon.<br />

Mr Schaeffer, this is your<br />

first edition as exhibition<br />

director. What are your expectations?<br />

“The exhibition has been<br />

sold out since June. We are<br />

very happy about how it was<br />

welcomed by the manufacturers<br />

and companies working in<br />

transport and logistics. This<br />

year, we should reach 95,000<br />

square meters exhibition<br />

space, increasing the visits of<br />

professionals. Let me say we<br />

come from the 2021 edition,<br />

in the middle of the pandemic,<br />

with 1,000 exhibitors and<br />

over 55,000 professional visi-<br />

“The big news is Stellantis coming<br />

with all their brands. Two years ago,<br />

they were not present. We consider<br />

Solutrans as the place where the<br />

companies and organizations can<br />

speak about energy transition in freight<br />

transportation”.<br />

tors. This year the fair will be<br />

more international and even<br />

bigger”.<br />

Compared to 2021, it seems<br />

that more OEMs are going<br />

to exhibit. What’s the reason,<br />

in your opinion?<br />

“We’ll have almost all the<br />

light and heavy vehicle manufacturers.<br />

Speaking of heavy<br />

trucks, Volvo decided not to<br />

come as their internal strategy,<br />

and we respect their decision.<br />

All the other manufacturers<br />

will be there, some of<br />

them launching new vehicles<br />

and products. Lyon will host<br />

the full ecosystem of the commercial<br />

transport, including<br />

cold chain, tyre manufacturers,<br />

energy suppliers and all<br />

the major organizations”.<br />

What about light commercial<br />

vehicles?<br />

“The big news is Stellantis<br />

coming with all their brands.<br />

For Guillaume<br />

Schaeffer,<br />

manager<br />

with quite a<br />

long-lasting<br />

experience in<br />

the MarCom<br />

department<br />

at Total,<br />

Solutrans<br />

<strong>2023</strong> will be<br />

the first edition<br />

as Managing<br />

Director.<br />

Two years ago, they were not<br />

present. We consider Solutrans<br />

as the real European<br />

event focusing on commercial<br />

transportation and we see<br />

Solutrans will be the place<br />

where the companies and organizations<br />

can speak about<br />

energy transition in freight<br />

transportation”.<br />

One of the main topics of<br />

this year’s exhibition is of<br />

course energy transition in<br />

the commercial vehicle sector.<br />

It’s not easy to tackle<br />

this topic in a thorough and<br />

attractive way. How will<br />

Solutrans face such issue<br />

this year?<br />

“It’s really the subject of the<br />

industry. Our mission is to<br />

support the players, making<br />

exhibitors able to face the<br />

subject. We have a huge conference<br />

programme. Just to<br />

make an example, we’ll speak<br />

about how the transition will<br />

be managed during the Olympic<br />

Games in Paris, 2024.<br />

Solutrans <strong>2023</strong> will host three<br />

main conference centers with<br />

more than 50 specialists.<br />

Some focuses are on the Low<br />

emission zones, the impact<br />

of logistics into the Olympic<br />

Games, car parks and retrofitting,<br />

how to finance zero<br />

emission trucks, for instance.<br />

The last day of the event is<br />

dedicated to employment, in<br />

“Small electric vehicles and cargo<br />

bikes are becoming crucial for urban<br />

transportation all over Europe. Some<br />

manufacturers have indeed extended<br />

their range, from big trucks to very<br />

small vehicles. These vehicles all have<br />

to be integrated”.<br />

collaboration with the national<br />

employment organization.<br />

Finally, the one we called<br />

‘One workshop, One energy’<br />

formula is very important to<br />

give exhibitors the opportunity<br />

to face the topics in an<br />

efficient way. It’s a formula<br />

with 4 workshops per day,<br />

a 35-minute themed pitch<br />

and 80 people per session<br />

allowed, targeted to vehicle<br />

manufacturers or any other<br />

company involved in research<br />

into fuels”.<br />

Urban mobility, the future<br />

of European cities, zero-emission<br />

vans and cargo<br />

bikes. What about those hot<br />

topics?<br />

“Low emission zones will be<br />

more and more widespread<br />

in Europe. We’re speaking<br />

about small electric vehicles<br />

and cargo bikes, for instance,<br />

which are becoming crucial<br />

for urban transportation all<br />

over the continent. We have<br />

also the retrofitting solutions<br />

presented at the show.<br />

Some manufacturers have<br />

indeed extended their range,<br />

from big trucks to very small<br />

vehicles. These vehicles all<br />

have to be integrated, up to<br />

cargo bikes. As for the latter,<br />

we will have a dedicated test<br />

area in Hall 1. Cargo bikes<br />

are increasingly widespread<br />

in Paris, for instance, but we<br />

can see them in other French<br />

cities, as well as other European<br />

capitals”.<br />

How is the test drive area<br />

conceived, this year?<br />

“We’ll be preparing two test<br />

tracks outside the exhibition<br />

grounds, as well as new<br />

spaces to host both exhibitors<br />

“After the pandemic, it’s become<br />

even more important to keep contact<br />

with the communities between an<br />

edition and the next one. That’s why<br />

we are thinking of organizing even<br />

more events and meetings in the<br />

meantime”.<br />

and visitors. We’ve thought of<br />

a sort of eco-friendly village<br />

named ‘Road testing village’<br />

that is made with former containers<br />

and wood structures,<br />

so re-usable materials in order<br />

to promote a more sustainable<br />

way. From here, test<br />

drives will be organized and<br />

planned.<br />

As we all know, trade fairs<br />

have been hugely affected<br />

by the pandemic. Is there<br />

some kind of legacy the Covid-19<br />

left in this sector? Has<br />

something changed when it<br />

comes to plan and organize<br />

an international exhibition<br />

like Solutrans?<br />

“The exhibitions are the place<br />

where people can meet all the<br />

actors of a sector in the same<br />

venue. It’s become even more<br />

important now to keep contact<br />

with the communities between<br />

an edition and the next one.<br />

That’s why we are thinking of<br />

organizing even more events<br />

and meetings in the meantime.<br />

Already in 2021, when<br />

the pandemic was still spreading,<br />

we provided the Solutrans<br />

digital. Now, we see such<br />

tools as a good way also for<br />

the visitors who are coming to<br />

see all that they could not visit<br />

during the show itself. That’s<br />

why we aim to make these<br />

digital tools more powerful in<br />

the future”.<br />

12<br />

13

FACE-TO-FACE<br />

TRATON GROUP’S CHIEF SUSTAINABILITY OFFICER<br />

FAR-SIGHTED VIEW<br />

When we at <strong>Sustainable</strong><br />

Truck&<strong>Van</strong> had<br />

our last conversation<br />

with Andreas Follér, he<br />

was Head of Sustainability at<br />

Scania. Now he’s Chief Sustainability<br />

Officer at TRA-<br />

TON: something has changed.<br />

“Shifting from a brand-centric<br />

focus to a Group-level perspective<br />

has made it necessary<br />

to find a way to ensure<br />

that all employees across this<br />

vast organization can collaborate<br />

seamlessly. While<br />

the strategies and solutions<br />

for addressing sustainability<br />

may vary among the different<br />

brands, my aim is to identify a<br />

complementary approach that<br />

fosters support and cooperation<br />

among our companies”,<br />

he said.<br />

Which action is Traton taking<br />

to fulfil the Paris Agreement<br />

targets?<br />

“We have three main approaches<br />

– user face, supply<br />

chain, and direct emissions<br />

from operations.<br />

“Talking about the Paris Agreement,<br />

both Scania and MAN have already<br />

obtained certified science-based<br />

carbon reduction targets. Navistar is<br />

progressing towards establishing its<br />

own, and VW Truck & Bus has a leading<br />

position in South America”.<br />

Both Scania and MAN have<br />

already obtained certified<br />

science-based carbon reduction<br />

targets, and Navistar is<br />

progressing towards establishing<br />

its own. Additionally,<br />

Volkswagen Truck & Bus is<br />

expected to take a leading<br />

position in the Latin American<br />

market, although the pace of<br />

electrification in the region<br />

appears to be somewhat slower.<br />

As part of the TRATON<br />

Group, we are fully dedicated<br />

to aligning Scania, MAN,<br />

Navistar and Volkswagen<br />

Truck & Bus and our product<br />

offerings with the objectives<br />

of the Paris Agreement by<br />

adhering to science-based targets.<br />

Achieving this alignment<br />

necessitates a comprehensive<br />

360-degree approach to decarbonization”.<br />

The major TRATON brands<br />

are investing a lot to manufacture<br />

EV batteries in-<br />

Currently<br />

serving<br />

as Chief<br />

Sustainability<br />

Officer at<br />

TRATON,<br />

Andreas<br />

Follér plays<br />

a crucial role<br />

in integrating<br />

sustainable<br />

practices and<br />

technologies<br />

within<br />

TRATON<br />

Group’s<br />

operations.<br />

house. Why are such investments<br />

worthy?<br />

“We have opted not to produce<br />

battery cells internally<br />

as part of our strategy. Instead,<br />

we are focused on establishing<br />

partnerships and<br />

collaboration with leading<br />

battery cell manufacturers.<br />

This collaborative effort involves<br />

integrating, researching,<br />

and jointly developing<br />

electric vehicle (EV) cells<br />

tailored specifically for heavy<br />

goods vehicles (HGVs).<br />

At the beginning of September,<br />

we have indeed inaugurated<br />

our state-of-the-art battery<br />

factory in Södertälje, Sweden.<br />

This facility will play a<br />

crucial role in our operations,<br />

as it will receive battery cells<br />

from Northvolt. These cells<br />

will then be processed into<br />

modules and subsequently<br />

assembled into packs, which<br />

will be integrated into our<br />

vehicles. Importantly, this<br />

battery factory is conveniently<br />

located adjacent to our Scania<br />

chassis assembly plant,<br />

streamlining our production<br />

processes”.<br />

We know that both Scania<br />

and MAN are working on<br />

hydrogen-powered trucks,<br />

even though it’s not clear<br />

when they’ll be available<br />

on the market. How promising<br />

is such technology for<br />

“We have opted not to produce<br />

battery cells internally as part of our<br />

strategy. Instead, we are focused<br />

on establishing partnerships and<br />

collaboration with leading battery cell<br />

manufacturers. Scania has recently<br />

opened its facility in Södertälje”.<br />

heavy-duty transport? And<br />

will it only be fuel cells or<br />

even hydrogen-powered<br />

ICEs?<br />

“We are working within our<br />

R&D departments on these<br />

technologies.<br />

Scania may be the only OEM<br />

that currently has, and has<br />

had for a year or two now,<br />

fuel cell trucks running in the<br />

streets of Sweden and Norway.<br />

We are definitely exploring<br />

these technologies more<br />

and more. I cannot answer<br />

today when we will launch<br />

more products like this, but<br />

we aren’t closing the door to<br />

any green technologies. The<br />

TRATON Group focuses on<br />

developing whichever technologies<br />

make the most sense<br />

for our customers”.<br />

There are lots of expectations<br />

about the MAN<br />

eTruck. Why is it important<br />

in the overall TRATON decarbonization<br />

strategy?<br />

“The preparation of first-generation<br />

e-Trucks by each of<br />

Scania, MAN, Navistar and<br />

Volkswagen Truck & Bus is<br />

a pivotal step. It signifies our<br />

dedication not only to our valued<br />

customers but also to the<br />

broader transport community.<br />

Our aim is to underscore our<br />

commitment and provide tangible<br />

solutions. These initial<br />

products will serve as invaluable<br />

learning experiences for<br />

us. We are committed to closely<br />

collaborating with our customers,<br />

ensuring a continuous<br />

cycle of improvement. Our<br />

primary goal is to enhance<br />

the user experience and facilitate<br />

the seamless operation<br />

of these cutting-edge technologies<br />

for our customers”.<br />

“I hold unwavering confidence in the<br />

capable management team and the<br />

dedicated individuals involved in the<br />

Milence project we share with Daimler<br />

Truck and Volvo. I eagerly anticipate<br />

the launch of the first charging point as<br />

a significant milestone”.<br />

Finally, the Milence project<br />

has quite ambitious targets<br />

and not so much time ahead<br />

to achieve them. Are you<br />

still confident about it?<br />

“Milence represents a collaborative<br />

effort between<br />

the TRATON Group, Daimler<br />

Truck, and Volvo Group.<br />

While we are not directly<br />

involved in the operational<br />

management of the company,<br />

I hold unwavering confidence<br />

in their capable management<br />

team and the dedicated individuals<br />

contributing to Milence’s<br />

success.<br />

The team at Milence faces<br />

significant challenges in resolving<br />

the intricate issues<br />

surrounding the installation<br />

of charging points along Europe’s<br />

highway corridors.<br />

This can undoubtedly be a<br />

source of frustration.<br />

Nevertheless, it’s encouraging<br />

to witness a growing recognition<br />

of the imperative and<br />

economic viability of establishing<br />

charging infrastructure<br />

for heavy commercial<br />

road transport. This momentum<br />

is being driven by various<br />

stakeholders, including<br />

energy utilities, landowners,<br />

and policymakers. Milence<br />

is making notable strides in<br />

this regard, and I eagerly anticipate<br />

the launch of the first<br />

charging point as a significant<br />

milestone in this journey”.<br />

14<br />

15

COVER STORY<br />

MERCEDES eACTROS 600<br />

THE NEXT<br />

FLAGSHIP<br />

For the model’s history and for what the<br />

eActros in particular represents and means,<br />

not only to Mercedes, the launch<br />

of the battery-powered ‘600’, the first truck<br />

expressly designed and built for long-haul<br />

transport, would have deserved a more prestigious<br />

setting than the Break autohof Hamburg<br />

Nordheide, the albeit very modern and somewhat<br />

unique service area (equipped, among<br />

other things, with a freeflow parking system<br />

for trucks with reservation facilities, a multienergy<br />

point, three-star hotel, stores, lounge<br />

area, and even a brewery). The service area<br />

is located in Egestorf, a small municipality in<br />

Lower Saxony, about half an hour’s drive south<br />

of Hamburg on the A7 route.<br />

Conversely, the very decision of the company’s<br />

top management to raise the curtain<br />

on their much-anticipated zero-emission road<br />

flagship in this location that makes utmost<br />

sustainability its pride, should be understood<br />

as a desire to immediately drop into the road<br />

and daily use a heavyweight truck that, in the<br />

words of Karin Radström, Ceo of Mercedes-<br />

Benz Trucks, “like no other Mercedes’s truck<br />

before, represents the transformation of road<br />

freight transport toward carbon neutrality”.<br />

Design first<br />

Another turning point, but this time it is even<br />

more important than what the Actros has been<br />

able to do in its nearly 30 years of file, always<br />

under the banner of hi-tech and elegance and<br />

with the ambition, looking at contents, to set itself<br />

as a genuine benchmark. With the eActros<br />

600, Mercedes now looks even further ahead,<br />

to the future precisely, intending to redefine<br />

the standards of freight transport in terms of<br />

technology, sustainability and design.<br />

The e-truck sales will begin no earlier than<br />

2025, since the eActros will not enter series<br />

production in Wörth until the end of next year,<br />

after the first fifty or so units are built, some of<br />

which will be tested in daily use by customers<br />

themselves.<br />

Of course, it is the first feature of the vehicle<br />

that leaps to the eye. This is a new styling<br />

language, which Mercedes has set up and de-<br />

Equipped with three lithium-iron-phosphate battery packs with<br />

a total installed capacity of 621 kWh for 500 km of range,<br />

Mercedes eActros 600 electric truck model features a design<br />

developed with the highest aerodynamic efficiency<br />

in mind. Series production will start not before 2025.<br />

16<br />

17

COVER STORY<br />

Highlights<br />

Model type Mercedes eActros 600<br />

Est. range<br />

500 km<br />

Battery type lithium iron phospate (LFP)<br />

Battery capacity<br />

621 kWh<br />

E-motor power (cont.) 400 kW (543 hp)<br />

E-motor power (peak) 600 kW (815 hp)<br />

Start of sales by <strong>2023</strong><br />

Series production end of 2024<br />

Testing the truck.<br />

Sales of the new<br />

Mercedes-Benz<br />

eActros 600 will<br />

begin in 2024,<br />

while production<br />

will start in 2025. In<br />

the meantime, the<br />

truck will be tested<br />

under challengin<br />

conditions all over<br />

Europe.<br />

veloped by aiming not so much and not only<br />

at the creation of a modern and attractive line<br />

in looks, but by aiming to achieve greater aerodynamic<br />

efficiency. Well, the result is fully<br />

achieved, as thanks to the 80 mm longer<br />

front end and airflow improving solutions, the<br />

Pro Cabin’s CX coefficient is 9 percent lower<br />

than the current Actros with a diesel engine.<br />

This translates into lower energy consumption,<br />

which benefits driving range.<br />

Named after its battery capacity<br />

At the inside, the heart of the vehicle is three<br />

battery packs, each with a capacity of 207<br />

kWh, thus 621 kWh in total. This, thanks to<br />

lithium-iron-phosphate cell technology, ensures<br />

the use of more than 95 percent of the installed<br />

capacity.<br />

The combination with the 800-volt electric<br />

axle (designed and developed by Mercedes itself)<br />

with two electric motors and four-speed<br />

transmission capable of generating 400 kW<br />

continuous power (600 kW peak), results in<br />

what the company calls “vigorous acceleration”<br />

and the almost uninterrupted availability<br />

of torque.<br />

Range and price<br />

The driving range of this Mercedes’ heavyweight<br />

truck is claimed to be 500 kilo-<br />

meters. In truth, they are still very little for a<br />

vehicle dedicated to long distance. Mercedes<br />

itself, however, claims that 60 percent of its<br />

customers’ long-haul trips are made over distances<br />

of less than 500 kilometers.<br />

Last, but not least, there are the issues of<br />

price (about two and a half times that of a thermal<br />

engine truck) and charging infrastructure,<br />

which are rapidly developing all over Europe<br />

(let’s remind that Daimler Truck is involved in<br />

the Milence project, together with Traton and<br />

Volvo, with the target to build at least 1,700<br />

public stations by 2026), but at the moment<br />

are totally insufficient for the needs of a 44-ton<br />

truck. However, that is a different matter.<br />

18<br />

19

PREVIEW<br />

RENAULT TRAFIC E-TECH<br />

ELECTRIC<br />

AWARENESS<br />

On the sustainability chessboard, understood<br />

as the offer of full electric vehicles,<br />

Renault can now deploy its team<br />

in full force: Master, Kangoo and Trafic, with<br />

the latter in the role of leading edge of a trident<br />

that actually needs no introduction, since the<br />

corresponding versions equipped with a combustion<br />

engine already are points of reference<br />

in their respective market segments.<br />

After all, speaking of the Trafic, a best seller<br />

that has been on the market for over forty years<br />

(the first model was launched in 1980) and has<br />

to its credit something like over 2.4 million vehicles<br />

produced and sold, well, it is clear what<br />

type of appreciation and consideration it can<br />

enjoy from professional customers, even the<br />

most demanding ones.<br />

The strength of the Trafic, the third best-selling<br />

light van in Europe, is being a model perfectly<br />

calibrated to fulfill the various missions<br />

in urban and interurban areas. Modern and elegant<br />

in its line, which was gradually refined<br />

over time, it remains aesthetically attractive<br />

Renault’s popular medium-sized van, in the full electric<br />

version, adds sustainability to the recognized strengths that<br />

make it one of the most appreciated vans. No compromises<br />

in terms of modularity and customization compared to the<br />

variants with combustion engine and driving range up to 300 km.<br />

20<br />

21

PREVIEW<br />

Highlights<br />

Model type Renault Trafic E-Tech<br />

Est. range<br />

297 km (WLTP)<br />

Battery type<br />

lithium-ion<br />

Battery capacity<br />

52 kWh<br />

AC charger<br />

up to 22 kW<br />

DC charger<br />

up to 50 kW<br />

Est. charging time (DC) 60 min (15-80%)<br />

E-motor max. power 90 kW (122 hp)<br />

E-motor max. torque<br />

245 Nm<br />

Always connected.<br />

Through the My<br />

Renault App or with<br />

the standard Easy<br />

Link multimedia<br />

system, the Trafic<br />

can count on a<br />

rich bouquet of<br />

specific services<br />

for full electric<br />

vehicles, including<br />

battery charging<br />

programming.<br />

thanks to the exact proportion between the<br />

living space for the driver and passengers as<br />

well as the space dedicated to freight. This<br />

compartment has well-designed volumes right<br />

from the entry versions, as well as easily accessible<br />

through double rear doors and large<br />

single or double side openings. Added to all<br />

this are high performances ensured by its proven<br />

kinematics, which is characteristic of the<br />

entire range and offers extensive customization<br />

possibilities.<br />

A complete and thorough range<br />

Now, this range is expanding to the essential<br />

battery version, that is full electric with zero<br />

emissions. Talking about range, in this case, is<br />

not at all an exaggeration. The Renault Trafic<br />

<strong>Van</strong> E-Tech Electric is offered in two lengths<br />

(5,080 and 5,480 mm), in as many heights<br />

(1,967 and 2,498 mm), with load compartment<br />

volumes from 5.8 to 8.9 cubic meters depending<br />

on the version and the possibility, for the Trafic<br />

L2, of a 4,150 mm loading length obtained by<br />

exploiting the through bulkhead located in correspondence<br />

with the passenger seat. To all this,<br />

the Trafic <strong>Van</strong> E-Tech Electric adds robustness<br />

and the ability to transport large loads, summed<br />

up by the 1,100 kilos payload.<br />

The heart of the electric Trafic is the 122<br />

horsepower (90 kW) motor with 245 Nm of<br />

torque. It is powered by the lithium ion battery<br />

(guaranteed for 8 years or 160 thousand<br />

km, with free replacement if the capacity drops<br />

below 70 percent of the nominal value) with<br />

a capacity of 52 kWh. The range is up to 297<br />

km before recharging, which is entrusted to the<br />

combined AC 7 kW plus AC 22 kW on-board<br />

charger (it is part of the standard equipment<br />

and allows you to recover 50 km of autonomy<br />

in less than 25 minutes). It is completed by the<br />

50 kW direct current charger.<br />

Behind the wheel, you can enjoy the pleasure<br />

of silent and brilliant driving (with the Eco<br />

mode guaranteeing optimal range management,<br />

while the ARBS system maximizes energy recovery).<br />

The electric Trafic is also offered as<br />

an always connected vehicle. Through the My<br />

Renault smartphone app, or with the Renault<br />

Easy link multimedia system, the driver can<br />

access, depending on their needs, a series of<br />

connected services specific to electric vehicles.<br />

This is another Trafic’s gem.<br />

22<br />

23

PREVIEW<br />

RENAULT TRUCKS<br />

THE BRAND-NEW<br />

ADDITION<br />

WELCOME CARGO BIKES<br />

Thorough range.<br />

From 44 tons up<br />

to the cargo bikes<br />

for ‘last’ last mile<br />

distribution. Renault<br />

Trucks counts<br />

on a complete<br />

zero-emission<br />

vehicle range to<br />

be recognized as<br />

a primary electric<br />

commercial vehicle<br />

brand. The E-Tech<br />

T and C range will<br />

debut in Lyon.<br />

Announced a little less than a year ago,<br />

the heavy electric vehicles in the Renault<br />

Trucks range are set to make their<br />

debut right at Solutrans, the company’s ‘home’<br />

fair, which has its headquarters in Lyon. Expected<br />

to complete a range that has recently<br />

been enriched, on the opposite side, by the<br />

medium-sized Trafic van, the E-Tech T and C<br />

by Renault Trucks are designed for regional<br />

transport and construction, respectively. All,<br />

strictly, with zero emissions.<br />

As for design, the new Diamond logo stands<br />

out. It is set in a fabric composed of the typical<br />

Renault Trucks chose its home trade show, Solutrans,<br />

to preview its heavy-duty electric E-Tech T and C trucks for<br />

regional distribution and construction, which are on their way<br />

to series production. One more step toward the goal<br />

of selling only ‘zero-emission’ vehicles in 2040.<br />

graphic elements of the French manufacturer’s<br />

E-Tech line: thus, blue hubcaps, vertical stripes<br />

on the vehicle sides, and distinctive E-Tech license<br />

plate, precisely, at the front.<br />

With safety in mind<br />

In addition, with the aim of optimizing the<br />

overall safety, the truck front has been moved<br />

forward <strong>11</strong>5 millimeters and radars have<br />

been placed on the sides. The chassis is also<br />

equipped with a platform that can be modified<br />

to optimize battery space. The completely reworked<br />

grille is inspired by the world of elec-<br />

tronic music, with a design reminiscent of an<br />

equalizer. The vehicle front is fully painted to<br />

reinforce the electromechanical idea.<br />

Modular battery platform<br />

We will know more, precisely, in Lyon, for one<br />

of the most anticipated ‘unveiling’ of Solutrans<br />

<strong>2023</strong>. All to be discovered, for example, is the<br />

battery configuration, as well as the power delivered<br />

by the electric motor. The heavy-duty<br />

trucks in the E-Tech range – it is much certain<br />

– will be manufactured at the Renault Trucks<br />

plant in Bourg-en-Bresse, not far from Lyon.<br />

A matter of ‘zero emission’ range<br />

breadth: first among European<br />

manufacturers, Renault Trucks has<br />

committed itself to a very particular<br />

segment of vehicles such as cargo<br />

bikes designed to integrate freight<br />

transport in urban centers with very<br />

light vehicles and, above all, with zero<br />

impact on the environment. The idea is<br />

to entrust electric bikes with last-mile<br />

deliveries, within an integrated system<br />

with larger vehicles such as trucks and<br />

vans. This cargo bikes project is shared<br />

with Kleuster, a manufacturer also<br />

headquartered in Lyon.<br />

Moving up the segment, we find the Trafic<br />

E-tech, the Master E-Tech, the D and D<br />

Wide E-Tech (the latter is also available in<br />

LEC, Low Entry Cabin), and the brand new T<br />

and C E-Tech series.<br />

Talking about batteries, for example, it is easy<br />

to imagine how the concept of modularity has<br />

been carried forward, as it has characterized<br />

distribution vehicles since the Z.E. line.<br />

The trade show debut of Renault Trucks’<br />

E-Tech T and C trucks coincides with the start<br />

of series production – this is another, by no<br />

means minor, step on the road to the oft-ballyhooed<br />

goal of getting to selling only electric or<br />

fuel-cell commercial vehicles in 2040.<br />

24<br />

25

FOCUS. CHINA<br />

THE ELECTRIC REVOLUTION<br />

WATCH OUT THE<br />

DRAGON<br />

China has been riding the electric revolution<br />

since the early years of the new millennium.<br />

This has allowed them to accumulate<br />

a significant competitive advantage that<br />

Western manufacturers are now struggling to<br />

close. It is no coincidence, therefore, that authoritative<br />

newspapers such as the New York<br />

Times have written that, in the transition towards<br />

electric mobility, “the only winner so far<br />

is China”, also arguing that Western countries<br />

may have to wait decades to close the technological<br />

gap between them and the Dragon. All<br />

this despite the ambitious goals that the EU<br />

has set itself and despite the great effort that<br />

the United States guided by President Biden<br />

are making to stimulate electric mobility by<br />

investing over 200 billion dollars.<br />

Let's get local<br />

A very significant piece of data was released<br />

by the China Passenger Car Association, according<br />

to which in the first half of <strong>2023</strong> (for<br />

the second time in history) local manufacturers<br />

surpassed foreign ones in car sales for<br />

How did China create a cutting-edge automotive industry in<br />

alternative traction? And will the offensive launched against<br />

Western manufacturers in the automotive sector also be<br />

replicated among commercial vehicles? Maybe it is still early<br />

to say, but data and trends can suggest some answers.<br />

26<br />

27

FOCUS. CHINA<br />

EYE ON: YUTONG<br />

With a dedicated global event held in June in Zhengzhou,<br />

China, primary truck and bus manufacturer Yutong introduced<br />

the so-called YEA (Yutong Electric Architecture). It’s an<br />

advanced, scalable and self-evolving EV architecture that<br />

enhances the Chinese manufacturer’s CVs through a native<br />

powertrain design. The new architecture integrates hardware<br />

and software and was developed in-house. The YEA can<br />

improve computing power by 200% and control efficiency by<br />

100%. Yutong is considering selling trucks even outside China.<br />

Farizon Auto,<br />

the new energy<br />

commercial vehicle<br />

manufacturer<br />

belonging to the<br />

Geely Group, is<br />

targeting indeed<br />

the European<br />

market. The<br />

international launch<br />

of the newly-built<br />

SuperVAN with<br />

an innovative and<br />

modular design will<br />

be in 2024.<br />

the Chinese domestic market, reaching 54%<br />

of total sales. These were naturally driven by<br />

sales of electric and hybrid cars, which reached<br />

3.5 million in the first half of the current year<br />

alone, more or less a third of the total.<br />

Compared to the automotive sector, the situation<br />

in the ‘heavy-duty’ industry is much<br />

more fluid, with the main Chinese brands still<br />

focused above all on the domestic market,<br />

which has by far the most important volumes<br />

globally. In the first half of <strong>2023</strong>, according to<br />

Interact Analysis, 104,000 electric buses and<br />

trucks were sold, a 57% increase compared to<br />

the first half of 2022. A growth driven above all<br />

by lower tonnage vehicles, in particular light<br />

trucks, which grew by 45%, with approximately<br />

30,000 units throughout China. Significant<br />

figures are also starting to be recorded with<br />

regard to heavy trucks, with approximately<br />

<strong>11</strong> thousand vehicles marketed in the first six<br />

months of <strong>2023</strong>. To make an example, in Europe<br />

(Switzerland and Norway included), just<br />

over a thousand trucks with a gross vehicle<br />

weight equal to or greater than 16 tonnes were<br />

sold throughout 2022.<br />

Electric trucks, a Chinese thing<br />

It is therefore not surprising that, again according<br />

to Interact analysis’ experts, 9 of the top 10<br />

brands for global electric truck registrations in<br />

2022 are Chinese: the ranking is led by Sany<br />

with a 13% share, ahead of Xcmg and Geely,<br />

just under 10%, and Yutong with 7%. The only<br />

exception to the Dragon’s excessive power is<br />

Volvo Trucks with a 4 percent share and 1,2<strong>11</strong><br />

registered vehicles.<br />

In the first half of this year, Geely itself re-<br />

corded rapid growth on the Chinese market.<br />

This statistic, however, takes buses into consideration,<br />

with a market share rising from <strong>11</strong><br />

to 26% of total registrations, also thanks to the<br />

Farizon car brand dedicated to new generation<br />

vans. Also seeing strong growth this year is<br />

Chery, and Foton, a manufacturer with strong<br />

specialization in freight transport, and one of<br />

the very first to approach the European market.<br />

So, what should we expect from the evolution<br />

of the Chinese heavy automotive sector in the<br />

near future? According to analysts cited by the<br />

Cnevpost website, by 2025, 16% of heavy-duty<br />

trucks sold in China will be electric. And there<br />

is great confidence in the potential of battery<br />

swapping, for which around half of the BEV<br />

trucks currently circulating in China are already<br />

equipped.<br />

In addition to the sectors of waste collection<br />

or street cleaning, which are highly influenced<br />

by public policies, transport relating to the coal<br />

industry or steel production will be the areas<br />

most permeated by electric mobility, while<br />

issues related to vehicle autonomy remain in<br />

long-distance transport.<br />

And all signs suggest that the European market,<br />

even more than the American one, which<br />

is currently more influenced by duties, could<br />

become the main target for Chinese manufacturers<br />

also among commercial vehicles.<br />

28<br />

29

INNOVATIONS<br />

SCANIA<br />

THE SUN IS<br />

SHINING<br />

It comes to mind when, a few years ago,<br />

Scania strongly argued that there would not<br />

be a single recipe capable of eliminating<br />

emissions and thus making a decisive impact<br />

on solving the issue of protecting the environment.<br />

Precisely that belief was at the basis of<br />

the Swedish brand’s decision not to impose a<br />

single specific technology on the market.<br />

Now, with the aim of reducing emissions but<br />

also operating costs at the same time, Scania<br />

has participated in a so far unique project. It<br />

was initiated and conducted in partnership with<br />

Uppsala University, Eksjö Maskin&Truck,<br />

By starting the tests of the road tractor with a plug-in hybrid<br />

motor coupled to a trailer ‘clad’ in solar panels capable of<br />

generating energy for the powertrain, Scania is taking sustainable<br />

transport into a new dimension. In the meantime, the battery<br />

assembly factory has been inaugurated in Södertälje.<br />

Midsummer, Ernsts Express, Delakraft, and<br />

financed partially by Vinnova, the government<br />

agency for the innovation and development of<br />

low environmental impact trucks.<br />

Increased battery capacity<br />

The protagonist is the 560 horsepower plug-in<br />

hybrid in three-axle configuration attached to<br />

an 18-meter long trailer covered in thin and<br />

light solar panels (these are as powerful as<br />

a house equipped with similar panels, have<br />

maximum efficiency of 13.2 kW at peak, and<br />

are estimated to be able to provide 8 thousand<br />

kWh of energy/year if used in Sweden). It is<br />

the first time that we have heard of solar panels<br />

used to generate energy for the powertrain. For<br />

their part, the batteries have a total capacity of<br />

300 kWh (100 on the tractor and 200 on the<br />

trailer).<br />

The vehicle uses tandem solar cells based<br />

on the combination of Midsummer and other<br />

perovskite cells: a solution which, by allowing<br />

greater efficiency in the process of transforming<br />

sunlight into electricity, would significantly<br />

increase energy production compared to that<br />

produced by panels. It follows that, if used<br />

in the sunniest countries of southern Europe,<br />

these panels could even quadruple the energy<br />

produced. The solar panel Scania will be tested<br />

by the transport company Ernsts Express on<br />

public roads, with the aim of collecting further<br />

data, verifying its efficiency and, who knows,<br />

also its possible feasibility in the near future.<br />

Battery production in Sodertälje ¨<br />

The range of innovations at Scania, however,<br />

does not stop here: at the beginning of<br />

September, the battery assembly factory was<br />

inaugurated with great fanfare in Södertälje.<br />

“A key tool to accelerate electrification,” said<br />

Christian Levin, president and CEO of Scania<br />

and the Traton Group. A strategic and decisive<br />

stage, especially if we consider that Scania<br />

aims to sell 50 percent of electric vehicles<br />

by 2030. The inauguration actually comes after<br />

the presentation, held last April, of a new<br />

cell developed jointly with Northvolt, which<br />

manufactures it in their gigafactory in northern<br />

Sweden. Starting in September, these cells<br />

have been assembled into battery packs in the<br />

new 18 thousand square meter plant in Södertälje,<br />

where 550 specialized operators work in<br />

a highly automated environment, effectively<br />

allowing the start of mass production of the<br />

Griffon electric range.<br />

The huge<br />

investment Scania<br />

made in Södertälje<br />

to build the newly<br />

inaugurated<br />

battery assembly<br />

factory goes side<br />

by side with the<br />

development of<br />

the company’s<br />

electric truck range.<br />

Production has<br />

lately commenced<br />

for trucks with R<br />

and S cabs with<br />

400 or 450 kW<br />

of engine power.<br />

These trucks<br />

feature new green<br />

battery packs and<br />

e-adopted chassis.<br />

30<br />

31

INNOVATIONS<br />

VOLVO TRUCKS<br />

CHALLENGE<br />

ACCEPTED<br />

GOLDEN HERITAGE<br />

The Volvo FH electric truck pictured<br />

above is the heir of a model that<br />

celebrates this year its 30 th anniversary.<br />

Almost 1.5 million Volvo FH units have<br />

been sold in the last thirty years in over<br />

80 countries all over the world. Engine,<br />

aerodynamics, driver comfort were only<br />

some of its breakthroughs.<br />

Volvo Trucks continues its journey toward electrification: new<br />

batteries with increased capacity for the mid-range (Volvo FL and<br />

FE Electric) are about to be launched. And to meet increasing<br />

demand of zero-emission vehicles, the Belgian factory in Ghent<br />

has been equipped for e-truck production.<br />

Volvo Trucks, the only European name<br />

in the 2022 electric truck sales top ten<br />

– which is basically monopolized by<br />

Chinese brands – confirms its vocation to play<br />

ahead in the field of zero-emission vehicles.<br />

And if the vehicles – whether medium or<br />

heavy-duty – are for all intents and purposes<br />

available on the market, now the challenge<br />

shifts to other elements: first and foremost, the<br />

vehicle’s range. Starting with the Volvo FL and<br />

FE Electric for distribution, the Swedish company<br />

(the only traditional manufacturer that did<br />

not attend Solutrans <strong>2023</strong>) promises to revolutionize<br />

the concept of range, relegating the<br />

infamous recharging issue to the past.<br />

How? By working on the battery composition<br />

to increase their capacity and reach the<br />

threshold of 450 kilometers in the case of the<br />

Volvo FL Electric and 275 kilometers in the<br />

case of the FE Electric. On closer inspection,<br />

these ranges are more than enough to allow<br />

truck users to be comfortable on their city or<br />

suburban trips. “With a range of up to 450 km,<br />

our electric trucks are ready to replace our customers’<br />

fleet of urban diesel trucks”, said Jessica<br />

Sandström, SVP Product Management at<br />

Volvo Trucks. “The Volvo FL and FE Electric<br />

produce minimal emissions and noise, benefiting<br />

the environment, the driver and everyone<br />

who lives and moves around the city”.<br />

A further boost to e-truck sales<br />

In the concept promoted by Volvo Trucks, having<br />

batteries with larger capacity allows fewer<br />

battery packs to be installed on the trucks, benefiting<br />

the vehicle’s payload, which is a crucial<br />

issue for those approaching electric mobility<br />

in freight transport. Volvo’s electric trucks that<br />

have been ‘upgraded’ with this new concept<br />

can be ordered immediately: the first deliveries<br />

are expected in 2024.<br />

The new development discussed here is expected<br />

to further boost sales of Volvo electric<br />

trucks. For this, another plant in Europe has<br />

recently been enabled to manufacture electric<br />

trucks. The plant is in Ghent, Belgium, and<br />

it is intended for the production of the heavy<br />

Volvo FH, Volvo FM and Volvo FMX Electric<br />

with total ground mass up to 44 tons. The Ghent<br />

plant is Volvo Trucks’ largest production<br />

site with an annual capacity of about 45,000<br />

trucks. Electric vehicles are assembled on the<br />

same platform and line as diesel and gas vehicles.<br />

The battery packs come from the recently<br />

inaugurated battery assembly plant in Ghent,<br />

which is located right next to the production<br />

line. The plant in Belgium is the fourth Volvo<br />

Trucks factory to produce battery electric vehicles<br />

after Blainville-sur-Orne, France; New<br />

River Valley in the U.S. for mass production of<br />

the VNR Electric; and Tuve, Sweden.<br />

Electric targets.<br />

Since Volvo Trucks<br />

started serial<br />

production of allelectric<br />

trucks in<br />

2019, the company<br />

has taken orders<br />

for around 6,000<br />

electric trucks in 42<br />

countries around<br />

the world. Volvo<br />

Trucks has set<br />

the target that by<br />

2030, half of the<br />

trucks sold by the<br />

company will be<br />

electric.<br />

32<br />

33

INNOVATIONS<br />

QUANTRON AG<br />

TRANSITION MADE<br />

EASIER<br />

We are not, and will not be in the future,<br />

an OEM: it would be impossible for<br />

us to compete with traditional manufacturers”,<br />

say in unison Michael Perschke<br />

and Andreas Haller, the fifth generation at the<br />

helm of the Haller group and ‘mastermind’ of<br />

the project. Rather, Quantron aims to act as a<br />

facilitator in a time of energy transition, leveraging<br />

the skills of a rapidly growing team to<br />

convert light, medium and heavy trucks with<br />

combustion engines into vehicles powered by<br />

batteries or fuel cells.<br />

So, retrofit specialists? Not really, and the<br />

A combination of a traditional manufacturer and a retrofit<br />

specialist, Quantron counts on their important know-how<br />

in zero-emission trucks to make it big even outside Germany.<br />

The launch of the heavy-duty QHM Aero is one of the cornerstones<br />

of a strategy that is increasingly shifting towards hydrogen.<br />

Quantron Days <strong>2023</strong> clearly showed this, with<br />

the official launch of the QHM Aero, the new<br />

MAN-based heavy vehicle with aerodynamics<br />

revisions by the Quantron engineering team led<br />

by Koorosh Shojaei.<br />

A brand-new front of the truck<br />