Engineering System - Siemens Automation and Drives Group

Engineering System - Siemens Automation and Drives Group

Engineering System - Siemens Automation and Drives Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Introduction<br />

<strong>System</strong> architecture<br />

SIMATIC PCS 7<br />

■ Overview<br />

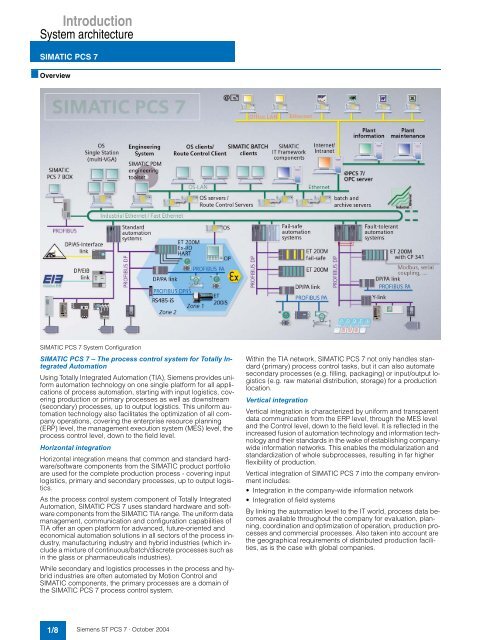

SIMATIC PCS 7 <strong>System</strong> Configuration<br />

SIMATIC PCS 7 – The process control system for Totally Integrated<br />

<strong>Automation</strong><br />

Using Totally Integrated <strong>Automation</strong> (TIA), <strong>Siemens</strong> provides uniform<br />

automation technology on one single platform for all applications<br />

of process automation, starting with input logistics, covering<br />

production or primary processes as well as downstream<br />

(secondary) processes, up to output logistics. This uniform automation<br />

technology also facilitates the optimization of all company<br />

operations, covering the enterprise resource planning<br />

(ERP) level, the management execution system (MES) level, the<br />

process control level, down to the field level.<br />

Horizontal integration<br />

Horizontal integration means that common <strong>and</strong> st<strong>and</strong>ard hardware/software<br />

components from the SIMATIC product portfolio<br />

are used for the complete production process - covering input<br />

logistics, primary <strong>and</strong> secondary processes, up to output logistics.<br />

As the process control system component of Totally Integrated<br />

<strong>Automation</strong>, SIMATIC PCS 7 uses st<strong>and</strong>ard hardware <strong>and</strong> software<br />

components from the SIMATIC TIA range. The uniform data<br />

management, communication <strong>and</strong> configuration capabilities of<br />

TIA offer an open platform for advanced, future-oriented <strong>and</strong><br />

economical automation solutions in all sectors of the process industry,<br />

manufacturing industry <strong>and</strong> hybrid industries (which include<br />

a mixture of continuous/batch/discrete processes such as<br />

in the glass or pharmaceuticals industries).<br />

While secondary <strong>and</strong> logistics processes in the process <strong>and</strong> hybrid<br />

industries are often automated by Motion Control <strong>and</strong><br />

SIMATIC components, the primary processes are a domain of<br />

the SIMATIC PCS 7 process control system.<br />

1/8<br />

<strong>Siemens</strong> ST PCS 7 · October 2004<br />

Within the TIA network, SIMATIC PCS 7 not only h<strong>and</strong>les st<strong>and</strong>ard<br />

(primary) process control tasks, but it can also automate<br />

secondary processes (e.g. filling, packaging) or input/output logistics<br />

(e.g. raw material distribution, storage) for a production<br />

location.<br />

Vertical integration<br />

Vertical integration is characterized by uniform <strong>and</strong> transparent<br />

data communication from the ERP level, through the MES level<br />

<strong>and</strong> the Control level, down to the field level. It is reflected in the<br />

increased fusion of automation technology <strong>and</strong> information technology<br />

<strong>and</strong> their st<strong>and</strong>ards in the wake of establishing companywide<br />

information networks. This enables the modularization <strong>and</strong><br />

st<strong>and</strong>ardization of whole subprocesses, resulting in far higher<br />

flexibility of production.<br />

Vertical integration of SIMATIC PCS 7 into the company environment<br />

includes:<br />

Integration in the company-wide information network<br />

Integration of field systems<br />

By linking the automation level to the IT world, process data becomes<br />

available throughout the company for evaluation, planning,<br />

coordination <strong>and</strong> optimization of operation, production processes<br />

<strong>and</strong> commercial processes. Also taken into account are<br />

the geographical requirements of distributed production facilities,<br />

as is the case with global companies.