Power Vented Gas Models FPSH/FPCR/FPST with ... - Geisel

Power Vented Gas Models FPSH/FPCR/FPST with ... - Geisel

Power Vented Gas Models FPSH/FPCR/FPST with ... - Geisel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

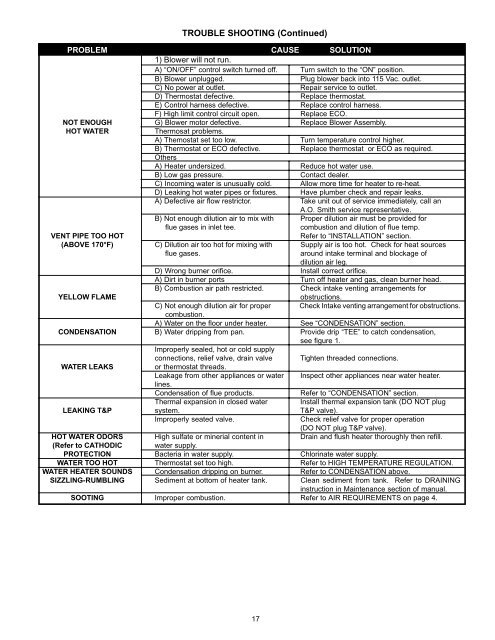

TROUBLE SHOOTING (Continued)<br />

PROBLEM CAUSE SOLUTION<br />

1) Blower will not run.<br />

A) “ON/OFF” control switch turned off. Turn switch to the “ON” position.<br />

B) Blower unplugged. Plug blower back into 115 Vac. outlet.<br />

C) No power at outlet. Repair service to outlet.<br />

D) Thermostat defective. Replace thermostat.<br />

E) Control harness defective. Replace control harness.<br />

F) High limit control circuit open. Replace ECO.<br />

NOT ENOUGH G) Blower motor defective. Replace Blower Assembly.<br />

HOT WATER Thermosat problems.<br />

A) Themostat set too low. Turn temperature control higher.<br />

B) Thermostat or ECO defective. Replace thermostat or ECO as required.<br />

Others<br />

A) Heater undersized. Reduce hot water use.<br />

B) Low gas pressure. Contact dealer.<br />

C) Incoming water is unusually cold. Allow more time for heater to re-heat.<br />

D) Leaking hot water pipes or fixtures. Have plumber check and repair leaks.<br />

A) Defective air flow restrictor. Take unit out of service immediately, call an<br />

A.O. Smith service representative.<br />

B) Not enough dilution air to mix <strong>with</strong> Proper dilution air must be provided for<br />

flue gases in inlet tee. combustion and dilution of flue temp.<br />

VENT PIPE TOO HOT Refer to “INSTALLATION” section.<br />

(ABOVE 170°F) C) Dilution air too hot for mixing <strong>with</strong> Supply air is too hot. Check for heat sources<br />

flue gases. around intake terminal and blockage of<br />

dilution air leg.<br />

D) Wrong burner orifice. Install correct orifice.<br />

A) Dirt in burner ports Turn off heater and gas, clean burner head.<br />

B) Combustion air path restricted. Check intake venting arrangements for<br />

YELLOW FLAME obstructions.<br />

C) Not enough dilution air for proper Check Intake venting arrangement for obstructions.<br />

combustion.<br />

A) Water on the floor under heater. See “CONDENSATION” section.<br />

CONDENSATION B) Water dripping from pan. Provide drip “TEE” to catch condensation,<br />

see figure 1.<br />

Improperly sealed, hot or cold supply<br />

connections, relief valve, drain valve Tighten threaded connections.<br />

WATER LEAKS or thermostat threads.<br />

Leakage from other appliances or water Inspect other appliances near water heater.<br />

lines.<br />

Condensation of flue products. Refer to “CONDENSATION” section.<br />

Thermal expansion in closed water Install thermal expansion tank (DO NOT plug<br />

LEAKING T&P system. T&P valve).<br />

Improperly seated valve. Check relief valve for proper operation<br />

(DO NOT plug T&P valve).<br />

HOT WATER ODORS High sulfate or minerial content in Drain and flush heater thoroughly then refill.<br />

(Refer to CATHODIC water supply.<br />

PROTECTION Bacteria in water supply. Chlorinate water supply.<br />

WATER TOO HOT Thermostat set too high. Refer to HIGH TEMPERATURE REGULATION.<br />

WATER HEATER SOUNDS Condensation dripping on burner. Refer to CONDENSATION above.<br />

SIZZLING-RUMBLING Sediment at bottom of heater tank. Clean sediment from tank. Refer to DRAINING<br />

instruction in Maintenance section of manual.<br />

SOOTING Improper combustion. Refer to AIR REQUIREMENTS on page 4.<br />

17