SKF Timing Belt Kits - SKF.com

SKF Timing Belt Kits - SKF.com

SKF Timing Belt Kits - SKF.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Failure analysis overview<br />

<strong>Timing</strong> belt<br />

The material in the belt is sensitive to bending<br />

(crimping) more than its maximum natural curve, and<br />

should therefore be treated gently.<br />

Common failure causes:<br />

1. Incorrect tension.<br />

2. Misalignment.<br />

3. Foreign object in the drive system (oil, cooling liquid,<br />

water, stone, etc).<br />

4. Contamination or uneven surface between the<br />

tensioner mounting plate and the engine block.<br />

5. Tensioner/Idler failure.<br />

6. Worn crankshaft or camshaft dampers.<br />

2. Misalignment (incorrect centering of the belt)<br />

The edge of the belt has been worn down to almost half its size. On<br />

the tensioner, you can see clear marks indicating a misaligned belt.<br />

4. Contamination on the belt<br />

If the belt has been contaminated with oil or water, you will see this by<br />

the glazing on the belt. You may feel it, as the belt will be soft and the<br />

rubber <strong>com</strong>ing away from the construction.<br />

12<br />

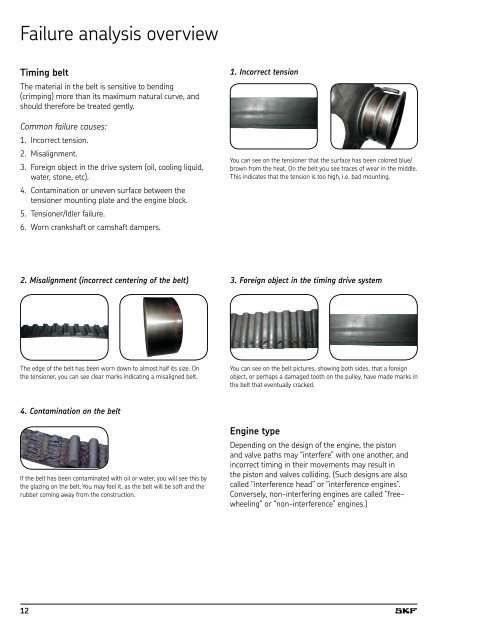

1. Incorrect tension<br />

You can see on the tensioner that the surface has been colored blue/<br />

brown from the heat. On the belt you see traces of wear in the middle.<br />

This indicates that the tension is too high, i.e. bad mounting.<br />

3. Foreign object in the timing drive system<br />

You can see on the belt pictures, showing both sides, that a foreign<br />

object, or perhaps a damaged tooth on the pulley, have made marks in<br />

the belt that eventually cracked.<br />

Engine type<br />

Depending on the design of the engine, the piston<br />

and valve paths may “interfere” with one another, and<br />

incorrect timing in their movements may result in<br />

the piston and valves colliding. (Such designs are also<br />

called “interference head” or “interference engines”.<br />

Conversely, non-interfering engines are called “freewheeling”<br />

or “non-interference” engines.)