SKF Timing Belt Kits - SKF.com

SKF Timing Belt Kits - SKF.com

SKF Timing Belt Kits - SKF.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Failure analysis overview<br />

Troubleshooting the ATBT set-up:<br />

1. The mounting bolt is not correctly torqued (to<br />

car manufacturer re<strong>com</strong>mendations). If it is not<br />

tightened, the tensioner will gradually loosen under<br />

running, and the indicator arm may <strong>com</strong>e into<br />

contact with the end stop. The engine begins to run<br />

rough as the timing is affected, before failing.<br />

2. Incorrect mounting (location pegs or holes are not<br />

correctly located).<br />

3. Correct set-up is not possible for proper running<br />

of the engine. Check for correct back plate locating<br />

point; some engines can indicate incorrect<br />

alternatives causing visual error.<br />

4. Unevenness between the mounted tensioner plate<br />

and the engine block can cause incorrect tension/<br />

belt run out or even block bearing rotation. Check for<br />

debris or possible fouling points on mounting.<br />

5. The indicator arm is not set to the correct tension<br />

position. You need to turn the engine twice to<br />

reconfirm a correct position. If it is not in the advised<br />

position, remount and perform the set up process<br />

again. Don’t take the risk, play it safe and be sure.<br />

Hydraulic tensioner<br />

Apart from the traditional weaknesses on the tensioner<br />

pulley <strong>com</strong>ponent, the actuator part can be affected by<br />

wear and premature failure.<br />

Common failure causes:<br />

1. An oil leakage through the seal. Even the smallest<br />

leak in the actuator through time will cause gradual<br />

loss of damping effect and possible belt damage<br />

(ripped teeth from poor tension may be found).<br />

2. Failure in the spring or valves will lead to system<br />

failure, and probably engine damage, very quickly.<br />

To maintain correct function, this damping control unit<br />

should be changed at the same period as the timing belt<br />

and pulleys (around 70,000 mi/around 110 000 km).<br />

14<br />

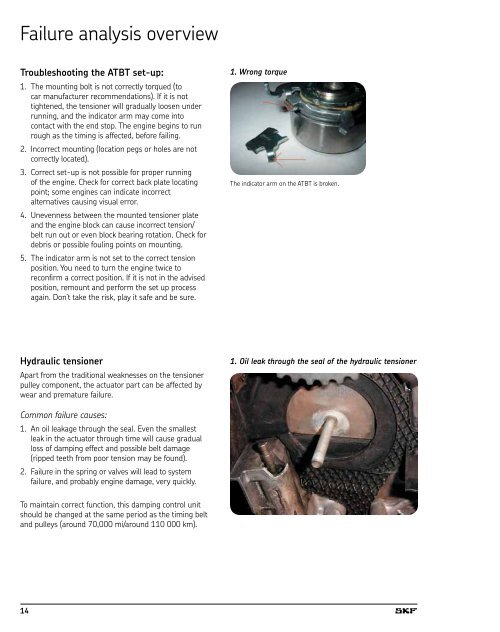

1. Wrong torque<br />

The indicator arm on the ATBT is broken.<br />

1. Oil leak through the seal of the hydraulic tensioner