special - Alu-web.de

special - Alu-web.de

special - Alu-web.de

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Giesel Verlag GmbH · Postfach 120158 · D-30907 Isernhagen · www.alu-<strong>web</strong>.<strong>de</strong> – PVST H 13410 – Dt. Post AG – Entgelt bezahlt<br />

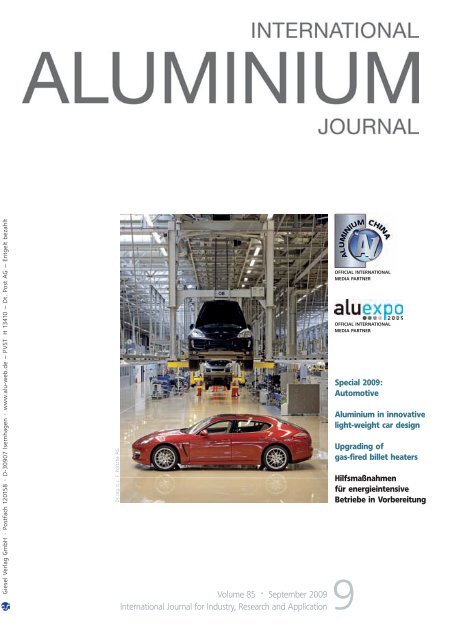

Dr. Ing. h.c. F. Porsche AG<br />

Volume 85 · September 2009<br />

International Journal for Industry, Research and Application<br />

OFFICIAL INTERNATIONAL<br />

MEDIA PARTNER<br />

OFFICIAL INTERNATIONAL<br />

MEDIA PARTNER<br />

Special 2009:<br />

Automotive<br />

<strong>Alu</strong>minium in innovative<br />

light-weight car <strong>de</strong>sign<br />

Upgrading of<br />

gas-fired billet heaters<br />

Hilfsmaßnahmen<br />

für energieintensive<br />

Betriebe in Vorbereitung<br />

9

Linear testing. Testing head for linear testing. Helical testing.<br />

Ultrasonic testing<br />

equipment<br />

There are many benefits in one-stop shopping –<br />

even for industrial goods. Reliable, cooperative<br />

planning, specifications, which meet exactly your<br />

<strong>de</strong>mands and individual service-packages to operate<br />

on first-class level throughout the whole lifetime of<br />

the plant – this can be realized by one of the most<br />

experienced suppliers: Hertwich Engineering.<br />

Major benefits<br />

Hertwich Engineering is <strong>de</strong>dicated to leading technology<br />

in the aluminum casthouse. We add value<br />

by <strong>de</strong>signing integrated turnkey solutions. From<br />

melting and remelting to testing and packing. The<br />

results are convincing: highest quality of products<br />

at lowest cost-of-ownership. This has been proven<br />

by numerous plants all over the world.<br />

HERTWICH ENGINEERING GMBH<br />

Weinbergerstrasse 6<br />

5280 Braunau, Austria<br />

Leading technology in the aluminum casthouse.<br />

Phone: +43 (0) 7722 806-0<br />

Fax: +43 (0) 7722 806-122<br />

Ultrasonic testing equipment<br />

Linear testing for inspection of center cracks<br />

Helical testing for 100 % <strong>de</strong>tection of metal<br />

volume<br />

- Designed to fulfil ASTM B594<br />

- Inspection of billets to Class A, as required<br />

for automotive and aerospace industries<br />

- Angle Beam technique for 100 % fault finding<br />

Faulty logs can be back tracked to mold number<br />

of casting station<br />

Statistical data analysis helps to pinpoint reasons<br />

for <strong>de</strong>fects and contributes to minimize scrap at<br />

the source<br />

E-mail: info@hertwich.com<br />

Internet: www.hertwich.com<br />

MEETING your EXPECTATIONS

Volker Karow<br />

Chefredakteur<br />

Editor in Chief<br />

<strong>Alu</strong>minium<br />

für umweltbewusste<br />

Mobilität<br />

<strong>Alu</strong>minium for<br />

environmentally<br />

aware mobility<br />

ALUMINIUM · 9/2009<br />

Die Automobilindustrie steckt weltweit<br />

in <strong>de</strong>r Krise. Sie ist von Überkapazitäten<br />

geprägt und viele traditionsreiche<br />

Autobauer haben in <strong>de</strong>n<br />

vergangenen Jahren zu wenig in innovative,<br />

von Leichtbau und Energieeffizienz<br />

gekennzeichnete Fahrzeug-<br />

und Motorenkonzepte investiert bzw.<br />

geforscht. Die Insolvenz von General<br />

Motors ist nur das sichtbarste Zeichen<br />

einer verfehlten Mo<strong>de</strong>llpolitik.<br />

Die Spuren <strong>de</strong>r Krise wer<strong>de</strong>n auch<br />

auf <strong>de</strong>r diesjährigen Internationalen<br />

Automobil-Ausstellung sichtbar sein,<br />

wenngleich sich die Branche selbstbewusst<br />

und mit zahlreichen Mo<strong>de</strong>llneuheiten<br />

präsentiert. Mit rund 700<br />

Ausstellern bleibt die IAA <strong>de</strong>utlich<br />

hinter <strong>de</strong>r Präsenz vor zwei Jahren<br />

zurück. Es sind vor allem die Zulieferer,<br />

die, unter <strong>de</strong>r Absatzkrise lei<strong>de</strong>nd,<br />

reihenweise auf eine Messeteilnahme<br />

in diesem Jahr verzichten.<br />

Der Verband <strong>de</strong>r Automobilindustrie<br />

(VDA) als Ausrichter zeigt sich<br />

trotz <strong>de</strong>s schwierigen wirtschaftlichen<br />

Umfel<strong>de</strong>s davon überzeugt, dass<br />

diese IAA ein Erfolg wird. VDA-Präsi<strong>de</strong>nt<br />

Matthias Wissmann verspricht<br />

ein „beeindrucken<strong>de</strong>s Innovationsfeuerwerk“<br />

und „Antworten auf die<br />

Anfor<strong>de</strong>rungen von heute und die<br />

Herausfor<strong>de</strong>rungen von morgen“. Die<br />

weitere Optimierung <strong>de</strong>r klassischen<br />

Antriebsarten – Clean Diesel und<br />

hoch aufla<strong>de</strong>n<strong>de</strong> Ottomotoren mit<br />

Direkteinspritzung – wer<strong>de</strong> auf <strong>de</strong>r<br />

IAA ebenso zu sehen sein wie die<br />

Fortschritte bei <strong>de</strong>r Elektrifizierung<br />

<strong>de</strong>s Automobils, vom Mild Hybrid bis<br />

zum Pkw mit reinem Elektroantrieb.<br />

Neben <strong>de</strong>r weiteren Reduzierung <strong>de</strong>s<br />

Verbrauchs und damit auch <strong>de</strong>r CO 2 -<br />

Emissionen stehen neuartige Assistenzsysteme<br />

im Vor<strong>de</strong>rgrund, die das<br />

Autofahren noch sicherer und komfortabler<br />

machen.<br />

Bei all<strong>de</strong>m darf <strong>de</strong>r Werkstoff <strong>Alu</strong>minium<br />

nicht vergessen wer<strong>de</strong>n. Das<br />

Leichtmetall hat sich längst seinen<br />

unverzichtbaren Platz im Automobil<br />

gesichert. Es trägt wesentlich dazu<br />

bei, die umweltpolitischen Ziele einer<br />

energieeffizienten und CO 2 -min<strong>de</strong>rn<strong>de</strong>n<br />

Mobilität zu realisieren. Das<br />

Special dieser Ausgabe zeugt davon,<br />

dass <strong>Alu</strong>minium als Guss-, Walz-,<br />

Strangpress- o<strong>de</strong>r Schmie<strong>de</strong>teil im<br />

Pkw eine feste Größe ist.<br />

e d i t o r i A l<br />

The automobile industry is still in<br />

crisis worldwi<strong>de</strong>. It is marked by excess<br />

capacities, and many automobile<br />

manufacturers, though rich in tradition,<br />

have invested or researched too<br />

little in innovative vehicles and engine<br />

concepts that embody lightweight<br />

construction and energy efficiency.<br />

The insolvency of General Motors is<br />

only the most easily visible sign of a<br />

policy mo<strong>de</strong>l that has failed.<br />

Traces of the crisis are also evi<strong>de</strong>nt<br />

at this year’s International Motor<br />

Show (IAA) in Frankfurt, Germany,<br />

even though the sector is presenting<br />

itself self-confi<strong>de</strong>ntly and with numerous<br />

mo<strong>de</strong>l innovations. With around<br />

700 exhibitors, this IAA is lagging<br />

substantially behind the exhibitor<br />

count of two years ago. And of course,<br />

it is mainly the supplier industries,<br />

which have been drastically affected<br />

by the sales crisis, that have given<br />

up participation in this year’s fair in<br />

droves.<br />

The German Association of the Automotive<br />

Industry (VDA), as organiser<br />

of the event, seems convinced that<br />

<strong>de</strong>spite the difficult economic environment<br />

this IAA will be a success.<br />

VDA Presi<strong>de</strong>nt Matthias Wissmann<br />

promises “an impressive array of innovations”<br />

and “solutions for today’s<br />

needs and tomorrow’s challenges”.<br />

The further optimisation of conventional<br />

drive systems such as clean diesel<br />

and supercharged gasoline engines<br />

with direct injection will be on show<br />

at the IAA, as also will advances in automotive<br />

electrification, ranging from<br />

mild hybrids to all-electric cars. The<br />

focus will be on a consistent further<br />

reduction of fuel consumption and<br />

CO 2 emissions, as well as on all-new<br />

assistance systems that make driving<br />

even safer and easier.<br />

In all this, the material aluminium<br />

should not be forgotten. The light<br />

metal has long secured for itself a key<br />

role in automotive engineering. It contributes<br />

substantially towards realising<br />

the environmental policy aims of<br />

energy-efficient and low-CO 2 mobility.<br />

The Special section in this issue<br />

shows that aluminium, whether in the<br />

form of castings, rolled products, extrusions<br />

or forged components, has an<br />

established and important role to play<br />

in automobiles.

i N H A l t<br />

14<br />

20<br />

22<br />

28<br />

Der ALUMINIUM-Branchentreff<br />

<strong>de</strong>s Giesel Verlags: www.alu-<strong>web</strong>.<strong>de</strong><br />

e d i t o r i A l<br />

<strong>Alu</strong>minium für umweltbewusste Mobilität ..................................<br />

A Kt U e l l e S<br />

Personen, Unternehmen, Märkte, Produkte ................................ 6<br />

W i r t S C H A F t<br />

Englischsprachige Artikel: s. nebenstehen<strong>de</strong>s Verzeichnis<br />

<strong>Alu</strong>miniumpreise .............................................................. 10<br />

Hilfsmaßnahmen für energieintensive Unternehmen in Vorbereitung ... 18<br />

S P e C i A l : A l U M i N i U M i M A U t o M o B i l<br />

Englischsprachige Artikel: s. nebenstehen<strong>de</strong>s Verzeichnis<br />

Porsche Panamera – eine Synthese aus<br />

Sportlichkeit, Komfort und Effizienz ....................................... 20<br />

BMW X1 – Premiumfahrzeug im Kompaktsegment .................... 21<br />

KS Kolbenschmidt: Technologiepaket bei Ottokolben ausgebaut ... 22<br />

Zylin<strong>de</strong>rköpfe von Honsel für die neuen VW-Dieselmotoren ......... 26<br />

Hochfeste <strong>Alu</strong>minium-Fahrwerksteile mit optimaler Topologie........ 4<br />

t e C H N o lo G i e<br />

Englischsprachige Artikel: s. nebenstehen<strong>de</strong>s Verzeichnis<br />

Kun<strong>de</strong>nspezifische, energieoptimierte<br />

Wärmebehandlungsanlagen für <strong>Alu</strong>minium .............................. 7<br />

Wärmebehandlungsanlagen für die <strong>Alu</strong>miniumindustrie ............... 40<br />

Mo<strong>de</strong>rnisierung von bestehen<strong>de</strong>n<br />

gasbeheizten Bolzenerwärmungsanlagen ................................ 41<br />

i N t e r N At i o N A l e B r A N C H e N N e W S ................... 47<br />

r e S e A r C H<br />

Englischsprachige Artikel: s. nebenstehen<strong>de</strong>s Verzeichnis<br />

V e r A N S tA lt U N G e N / d o K U M e N tAt i o N<br />

Englischsprachige Artikel: s. nebenstehen<strong>de</strong>s Verzeichnis<br />

Veranstaltung: Schweißen & Schnei<strong>de</strong>n, 14.-19. Sept. 2009 .......... 57<br />

Patente ......................................................................... 58<br />

Literaturservice ................................................................ 61<br />

Impressum ..................................................................... 81<br />

Vorschau........................................................................ 82<br />

B e Z U G S Q U e l l e N V e r Z e i C H N i S ............................ 64<br />

S t e l l e N A N G e B o t .................................................... 6<br />

4 ALUMINIUM · 9/2009

E D I T O R I A L<br />

<strong>Alu</strong>minium for environmentally aware mobility ........................... 3<br />

N E W S I N B R I E F<br />

People, companies, markets, products ..................................... 7<br />

E C O N O M I C S<br />

The curse of globalisation – must we expect crises<br />

in the aluminium industry that are more abrupt in future? .............. 14<br />

S P E C I A L : A U T O M O T I V E<br />

Porsche Panamera – a unique combination<br />

of comfort, performance and efficiency .................................. 20<br />

KS Kolbenschmidt: Gasoline engine piston<br />

technology packages expan<strong>de</strong>d ............................................ 22<br />

Cylin<strong>de</strong>r heads from Honsel for new VW diesel engines ............... 26<br />

<strong>Alu</strong>minium in innovative light-weight car <strong>de</strong>sign ........................ 28<br />

T E C H N O LO G Y<br />

Heat-treatment equipment for the aluminium industry ................ 40<br />

Upgrading of existing gas-fired billet heaters ............................ 41<br />

ABB maintenance turns around plant critical equipment .............. 43<br />

C O M PA N Y N E W S W O R L D W I D E<br />

<strong>Alu</strong>minium smelting industry ............................................... 45<br />

Bauxite and alumina activities .............................................. 47<br />

Recycling and secondary smelting ......................................... 48<br />

<strong>Alu</strong>minium semis .............................................................. 49<br />

On the move................................................................... 50<br />

Suppliers........................................................................ 51<br />

Alro – new annealing furnace put into operation ...................... 51<br />

R E S E A R C H<br />

On the dissolution of alumina in a<br />

low-melting electrolyte for aluminium production .......................... 52<br />

E V E N T S / D O C U M E N TAT I O N<br />

ALUMINIUM CHINA 2009 exceedingly successful ....................... 57<br />

Literature service .............................................................. 61<br />

Imprint .......................................................................... 81<br />

Preview ......................................................................... 82<br />

S O U R C E O F S U P P LY L I S T I N G ............................... 64<br />

ALUMINIUM · 9/2009<br />

Inserenten<br />

dieser Ausgabe<br />

List of advertisers<br />

C O N T E N T S<br />

This issue contains<br />

an enclosure from<br />

GDA Gesamtverband <strong>de</strong>r<br />

<strong>Alu</strong>miniumindustrie e. V.<br />

to which we draw<br />

your kind attention.<br />

41<br />

43<br />

Stellenangebot / Job advertisement 6<br />

Insolvenzversteigerung Scheffler GmbH 8<br />

ABB Switzerland Ltd., Schweiz 84<br />

Buss ChemTech AG, Schweiz 9<br />

Astech Angewandte Sensortechnik GmbH 23<br />

Coiltec Maschinenvertriebs GmbH 18<br />

Drache Umwelttechnik GmbH 35<br />

Edimet SpA, Italy 15<br />

Elpo GmbH 39<br />

GoIndustry Dove Bid, USA 7<br />

Hermann Gutmann Werke AG 27<br />

Haarmann Holding GmbH 31<br />

Hertwich Engineering GmbH, Österreich 2<br />

Inotherm Industrieofen-<br />

und Wärmetechnik GmbH 18, 27<br />

Messe Essen GmbH 17<br />

Reed Exhibitions Deutschland GmbH 11<br />

Sapa GmbH 19<br />

Zhengzhou Zhongshi Cell<br />

Technology Co., Ltd, China 13<br />

5

A k t u e l l e s<br />

trimet und Atag<br />

grün<strong>de</strong>n Joint Venture<br />

Die Trimet <strong>Alu</strong>minium AG, Essen, und die KS <strong>Alu</strong>minium-Technologie,<br />

Neckarsulm, wer<strong>de</strong>n künftig im<br />

<strong>Alu</strong>miniumdruckguss zusammenarbeiten. Dazu wur<strong>de</strong><br />

ein Joint Venture (KS Atag Trimet Guss GmbH) zur Herstellung<br />

von Zylin<strong>de</strong>rkurbelgehäusen aus <strong>Alu</strong>miniumlegierungen<br />

gegrün<strong>de</strong>t, das von bei<strong>de</strong>n Gesellschaften zu<br />

je 50 Prozent gehalten wird. Die Genehmigung <strong>de</strong>s Gemeinschaftsunternehmens<br />

mit Sitz in Harzgero<strong>de</strong> (Sachsen-Anhalt)<br />

durch das Bun<strong>de</strong>skartellamt ist erfolgt.<br />

Die KS Atag Trimet Guss wird mit <strong>de</strong>m Schwerpunkt<br />

Automotive die Kompetenzen <strong>de</strong>r Partner auf <strong>de</strong>n Gebieten<br />

<strong>de</strong>r Metallvere<strong>de</strong>lung, <strong>de</strong>r Gusstechnologie sowie<br />

<strong>de</strong>s Rohmaterial- und Energiemanagements zusammenführen<br />

und so Synergiepotenziale aus allen Bereichen<br />

nutzen. Bei<strong>de</strong> Partner führen ihre bestehen<strong>de</strong>n Produktionsstandorte<br />

weiter und bleiben auch künftig unter ihren<br />

eingeführten Produktnamen am Markt präsent. Das<br />

Joint Venture beschäftigt rund 50 Mitarbeiter.<br />

Wir suchen <strong>de</strong>n /die<br />

Stellenanzeige<br />

Verkaufs-Ingenieur /-in<br />

für <strong>de</strong>n Bereich <strong>Alu</strong>minium<br />

Aufgabengebiet:<br />

– Technische Beratung und<br />

Betreuung <strong>de</strong>r Kun<strong>de</strong>n<br />

– Erarbeitung individueller<br />

Feuerfest-Lösungen<br />

– Erschließung neuer und erweiterter<br />

Produkt- und Marktpotentiale<br />

Sie verfügen über ein abgeschlossenes Studium<br />

im Bereich Gießereitechnik, Schwerpunkt<br />

<strong>Alu</strong>minium, und haben i<strong>de</strong>alerweise bereits Er-<br />

fahrungen in <strong>de</strong>r <strong>Alu</strong>miniumindustrie gesammelt.<br />

Da Sie in einem internationalen Umfeld arbeiten,<br />

sind gute Englischkenntnisse von Vorteil.<br />

Wir erwarten Eigeninitiative, Durchsetzungs-<br />

kraft und Kreativität. Reisebereitschaft und die<br />

Freu<strong>de</strong> am Verkaufen machen Sie zu einem/-r<br />

i<strong>de</strong>alen Bewerber/-in für uns.<br />

Wir bieten ambitionierten Kandidaten eine<br />

nicht alltägliche Karrierechance in einem internationalen<br />

wachsen<strong>de</strong>n Unternehmen mit sehr<br />

guten Entwicklungschancen.<br />

Bitte richten Sie Ihre Bewerbung unter<br />

Berücksichtigung <strong>de</strong>r Chiffre-Nr AL-1759 an<br />

die Giesel Verlag GmbH, Postfach 12 01 58,<br />

30907 Isernhagen.<br />

ksM Castings erweitert<br />

<strong>Alu</strong>minium-Fahrwerksgießerei<br />

KSM Castings mit Sitz in Hil<strong>de</strong>sheim errichtete in <strong>de</strong>n<br />

Jahren 2001/02 am Standort Wernigero<strong>de</strong> eine <strong>de</strong>r mo<strong>de</strong>rnsten<br />

<strong>Alu</strong>minium-Fahrwerksgießereien in Europa<br />

und baute diese in <strong>de</strong>r Folge weiter aus. Anfang Mai 2009<br />

wur<strong>de</strong> eine zusätzliche Produktionshalle für jährlich drei<br />

Millionen Pumpengehäuse in Betrieb genommen.<br />

Im Juli dieses Jahres wur<strong>de</strong> <strong>de</strong>r zweite Ausbau <strong>de</strong>s<br />

Werkes abgeschlossen. Mit einer eigens für die Herstellung<br />

sicherheitsrelevanter Fahrwerksteile im Gegendruck-Kokillengussverfahren<br />

errichteten Fertigung für<br />

Porsche und VW baut KSM Castings damit auch in wirtschaftlich<br />

schwierigen Zeiten seinen Standort in Wernigero<strong>de</strong><br />

weiter aus.<br />

KSM Castings beschäftigt aktuell mehr als 200 Mitarbeiter<br />

am Standort Wernigero<strong>de</strong> und befin<strong>de</strong>t sich trotz<br />

<strong>de</strong>r Krise in <strong>de</strong>r Automobilindustrie dank mehrerer Neuaufträge<br />

weiterhin in einer Wachstumsphase. In <strong>de</strong>n Ausbau<br />

<strong>de</strong>s Werkes wur<strong>de</strong>n circa 25 Mio. Euro investiert.<br />

tube <strong>de</strong>s Jahres 2009 gekürt<br />

Auf <strong>de</strong>m diesjährigen Kongress in Istanbul feierte <strong>de</strong>r<br />

europäische Verband <strong>de</strong>r Tubenhersteller etma sein 50jähriges<br />

Bestehen. Auf mittlerweile 28 Jahre bringt es <strong>de</strong>r<br />

Branchenwettbewerb „Tube <strong>de</strong>s Jahres“, <strong>de</strong>r erstmals<br />

1981 durchgeführt wur<strong>de</strong>. Bei diesem Preis wählen sieben<br />

Experten aus <strong>de</strong>m etma-Mitglie<strong>de</strong>rkreis die jeweils<br />

beste und innovativste Tube in <strong>de</strong>n Kategorien <strong>Alu</strong>minium-,<br />

Laminat- und Kunststoff sowie Prototypen.<br />

Im Jubiläumsjahr 2009 erhielt bei <strong>de</strong>n <strong>Alu</strong>miniumtuben<br />

das Produkt „Essensity Soft Permanent Colour Cream“<br />

<strong>de</strong>r Firma Schwarzkopf Professional die meisten Stimmen.<br />

Hergestellt wur<strong>de</strong> die Tube von Tubex Wasungen<br />

aus Deutschland. Sie wur<strong>de</strong> mit einem weißen Mattlack<br />

mit speziellem Haptikeffekt versehen und mit <strong>de</strong>m Computer-to-Plate-Verfahren<br />

in einem bewusst puristischen<br />

Design bedruckt. Die Kombination aus hochwertigem<br />

weißen Mattlack, <strong>de</strong>n ins Auge fallen<strong>de</strong>n grünen Grafikelementen<br />

und <strong>de</strong>r auf das Druckbild abgestimmten Verschlussfarbe<br />

geben <strong>de</strong>r Tube ihre extravagante Note.<br />

etma<br />

ALUMINIUM · 9/2009

EAFA<br />

economic conditions hit alufoil production<br />

Given current economic conditions<br />

figures for the first half of 2009 show a<br />

13 percent fall in the European alufoil<br />

<strong>Alu</strong>foil tray<br />

production to 371,400 tonnes, compared<br />

to the corresponding period a<br />

year earlier.<br />

Thicker alufoil gauges, used mainly<br />

for the manufacture of semi-rigid<br />

foil trays and technical applications<br />

rusal agrees terms<br />

of <strong>de</strong>bt restructuring<br />

ALUMINIUM · 9/2009<br />

for the automotive and building sectors<br />

were the worst affected falling<br />

by 26 percent, while thinner gauges<br />

used mainly in flexible packaging<br />

and household foil were better off<br />

<strong>de</strong>clining by 7 percent.<br />

Despite this slump in production,<br />

representatives of the alufoil<br />

industry are looking ahead more<br />

optimistically than some months<br />

ago. “It is not all bad news for the<br />

alufoil sector as the one-off effect<br />

of stock reduction along the supply<br />

chain seems to be over”, says Stefan<br />

Glimm, Executive Director of<br />

the European <strong>Alu</strong>minium Foil Association<br />

(EAFA). “Data for the last<br />

two months show a bottoming out<br />

in particular for thicker gauges and<br />

exports.”<br />

<strong>Alu</strong>minium foil is an essential<br />

part of many flexible packaging and<br />

container applications. Other uses inclu<strong>de</strong><br />

automotive and heat exchange<br />

components, insulation material and<br />

many other industrial applications.<br />

UC Rusal has agreed the principal terms of a long-term <strong>de</strong>bt<br />

restructuring with the Coordinating Committee which represents<br />

more than 70 international len<strong>de</strong>rs. According to the<br />

agreement, Rusal will settle its <strong>de</strong>bt to international banks<br />

within seven years. The restructuring will be split into two<br />

phases. During the first period of four years, Rusal will focus<br />

on maximising efficiencies across the business and taking<br />

full advantage of the recovery in <strong>de</strong>mand. Rusal has periodical<br />

<strong>de</strong>bt reduction targets in place and will seek to repay a<br />

total of five billion US-dollars of <strong>de</strong>bt owed to all len<strong>de</strong>rs by<br />

the fourth quarter 2013.<br />

During this period principal repayments will be ma<strong>de</strong> on<br />

a ‘pay-if-you-can’ basis based on the performance of the business,<br />

thereby ensuring the full sustainability and integrity of<br />

its operations. Interest will be paid partly in cash, at a rate<br />

ranging from Libor +1.75% to 3.5%, with the remaining portion<br />

to be capitalised. Furthermore, in or<strong>de</strong>r to preserve cash<br />

for len<strong>de</strong>rs and the business, no divi<strong>de</strong>nds will be paid until<br />

the net <strong>de</strong>bt to Ebitda ratio reaches 3x.<br />

The second phase of the restructuring will involve the<br />

refinancing of the remaining <strong>de</strong>bt by existing len<strong>de</strong>rs for an<br />

additional three years. Such refinancing will be at Rusal’s<br />

option, as it may opt for an alternative refinancing of the<br />

<strong>de</strong>bt on market terms should this prove more favourable to<br />

the company.<br />

By Or<strong>de</strong>r of a Secured Creditor<br />

For more information and<br />

terms of sale, please visit<br />

www.Go-Dove.com<br />

N e w s i N b r i e F<br />

Zenergy to supply<br />

innovative induction<br />

heater to sapa Profili<br />

Zenergy Power has received a further<br />

commercial or<strong>de</strong>r for a low-energy,<br />

high-productivity induction heater.<br />

The facility, which is based on Zenergy’s<br />

superconductor technology, has<br />

been purchased by the Italian subsidiary<br />

of Sapa, Sapa Profili Srl.<br />

The induction heater or<strong>de</strong>red by<br />

Sapa will be used as a replacement<br />

for a conventional gas-fired heating<br />

furnace currently installed at its<br />

aluminium plant located in Bolzano,<br />

Northern Italy. It is anticipated that<br />

the replacement of the plant’s conventional<br />

equipment with Zenergy’s superconductor-based<br />

heater will lead<br />

to improved operational efficiency<br />

and thus enhance the plant’s overall<br />

commercial potential. In particular,<br />

Sapa will exploit the superconducting<br />

heater’s processing versatility to<br />

enable the heating of several different<br />

types of aluminium alloy at the same<br />

plant.<br />

(2) Complete <strong>Alu</strong>minum Extrusion<br />

Facilities of Signature <strong>Alu</strong>minum, Inc.<br />

Live & Webcast Auction<br />

Sale Date: Thursday, 24 th September 2009 at 10:00 AM CDT<br />

Auction Locations:<br />

Temroc Metals, 4375 Willow Drive, Hamel (Minneapolis),<br />

MN 55340 (Live & Webcast)<br />

Atlantic <strong>Alu</strong>minum, 18631 MC Highway 71, Lumber Bridge<br />

(Fayetteville), NC 28357 (Webcast only, to be sold from MN location)<br />

Inspection: Hamel - Wednesday, 23rd September 2009<br />

from 10:00 AM to 4:00 PM CDT or by appointment;<br />

Lumber Bridge – By Appointment Only<br />

Assets inclu<strong>de</strong>:<br />

• 5-Axis 6-Si<strong>de</strong>d CNC Profile Machining Center: Handtmann<br />

PBZ-NT-800 A.S. (2002)<br />

• 4-Axis CNC Vertical Machining Centers: (7) Haas; Fadal; Chiron<br />

• <strong>Alu</strong>minum Extrusion Presses, Billet Ovens, & Aging Ovens:<br />

(2) Sutton 1650-Ton; Wean 2250-Ton; Lombard 1250-Ton<br />

• Hydraulic Press Brakes: (6) Accurpress 150, 130, 100 & 60-Ton;<br />

Cincinnati 135-Ton<br />

• CMMs: (3) Brown & Sharpe (Late as 2002); Numerex<br />

• Toolroom Equipment: Mills; Lathes; Presses; Welding Systems;<br />

Cutoff Saws; Shot Blast & Inspection Equipment<br />

• Paint Line: Electrostatic<br />

• Material Handling & Plant Support Equipment: Bridge Cranes;<br />

Forklifts; Air Compressors; Parts; Spares; Office Equipment &<br />

Much More<br />

Also available as an entirety: Complete billet casting and<br />

extrusion facility with 4 press lines located in Greenville, PA.<br />

For further information, please contact: BRYAN GOODMAN<br />

Tel: +1 410 654 7500 ext. 235 Email: bryan.goodman@go-dove.com<br />

*Virtual Brochure is Available on the Website

A k t u e l l e s<br />

Europäischer <strong>Alu</strong>minium Kongress, 23./24. Nov. ‘09<br />

<strong>Alu</strong>minium im Automobil<br />

<strong>Alu</strong>minium ist ein unverzichtbarer Werkstoff im Automobil<br />

gewor<strong>de</strong>n: Gussteile für Kurbelgehäuse und als<br />

Strukturbauteile in <strong>de</strong>r Karosserie sind heute Stand <strong>de</strong>r<br />

Technik. Aber auch Halbzeuge und Schmie<strong>de</strong>teile fin<strong>de</strong>n<br />

in Fahrzeugen zunehmend Anwendung.<br />

Vor diesem Hintergrund veranstaltet <strong>de</strong>r Gesamtverband<br />

<strong>de</strong>r <strong>Alu</strong>miniumindustrie (GDA), Düsseldorf, am<br />

23./24. November 2009 einen europäischen Kongress<br />

zum Thema „<strong>Alu</strong>minium im Automobil – Werkstoff für<br />

Leichtbau und Design“. Auf <strong>de</strong>m Kongress wer<strong>de</strong>n sowohl<br />

die unterschiedlichen Einsatzmöglichkeiten von<br />

<strong>Alu</strong>minium, die <strong>de</strong>rzeit im Pkw verwen<strong>de</strong>t wer<strong>de</strong>n, vorgestellt<br />

und über mögliche Weiterentwicklungen diskutiert,<br />

die die Fahrzeuge <strong>de</strong>r Zukunft noch leichter und<br />

energieeffizienter wer<strong>de</strong>n lassen. Hochkarätige Vertreter<br />

aus <strong>de</strong>r Automobil- und <strong>Alu</strong>miniumindustrie sowie von<br />

Hochschulen wer<strong>de</strong>n innovative aktuelle und visionäre<br />

Lösungen präsentieren. Programminfos und Anmel<strong>de</strong>formulare<br />

unter www.aluminium-congress.com.<br />

Kontakt: Anncathrin Wener (GDA), Tel: 0211 4796 282,<br />

anncathrin.wener@aluinfo.<strong>de</strong><br />

INSOLVENZVERSTEIGERUNG<br />

Scheffler GmbH<br />

Dieselstraße 109 – 111, 33442 Herzebrock-Clarholz<br />

Di., 13. Oktober 2009, 10.00 Uhr<br />

12 <strong>Alu</strong>minium-Druckgussmaschinen, z.B. Frech DAK 720-71<br />

Zuhaltekraft 8.000 kN Bj. 04, 2x DAK 580-62 Zuhaltekraft 6.400<br />

kN Bj. 99/01, 3x DAK 450-40RC/54 Zuhaltekraft 5.000 kN Bj.<br />

01, DSD H 700 R Zuhaltekraft 7.000 kN Bj. 03, 6 4-Säulen-<br />

Hydraulik-Entgratpressen Reis z.B. SEP 9-30 Dialog, CLP-<br />

30D, SEP 9-100W, Presskraft 300-1.000 kN bis Bj. 99,<br />

<strong>Alu</strong>minium Schachtschmelzofen Striko MH 800/500 oel Etamax<br />

II Schmelzleistung 500 kg/h max. Betriebstemperatur 750<br />

°C Bj. 91, Durchlauf-Gleitschliffanlage Trowal/Schney<strong>de</strong>r m.<br />

Trockenkanal, 3 Rund-Gleitschliffanlagen Rössler R 300 A /<br />

RM 600, Wasseraufbereitungsanlage Rössler ZH 800 HA<br />

Turbo-Floc Bj. 00, kompl. Werkzeugbau mit CNC-Bearbeitungszentren,<br />

CNC-Drehmaschine Gil<strong>de</strong>meister, Werkzeugfräsmaschinen,<br />

Bohrmaschinen u.v.a.m.<br />

Besichtigung: Mo., 12. Oktober 2009 von 12.00 – 17.00 Uhr<br />

sowie am Versteigerungstag von 08.00 – 09.45 Uhr<br />

Zahlung: sofort bar, LZB-Scheck o. bankbestätigtem V-Scheck.<br />

Ausgabe <strong>de</strong>r Bieterkarte nur gegen eine Kaution von € 100,–.<br />

Ausführlicher Katalog unter www.industrie-rat.<strong>de</strong><br />

sowie Faxabruf 01805 / 77 69 66 07<br />

Gerhardi nimmt neue<br />

strangpresse in betrieb<br />

Im Beisein zahlreicher Gäste aus <strong>de</strong>m Kun<strong>de</strong>n- und Lieferantenkreis,<br />

von politischen Vertretern <strong>de</strong>r Lan<strong>de</strong>sregierung<br />

NRW, <strong>de</strong>s Märkischen Kreises und <strong>de</strong>r Stadt Lü<strong>de</strong>nscheid,<br />

<strong>de</strong>s Ausrüsters GIA und <strong>de</strong>r Industrie- und Han<strong>de</strong>lskammer<br />

zu Hagen und, natürlich, <strong>de</strong>s Gesellschafterkreises hat Gerhardi<br />

<strong>Alu</strong>technik GmbH & Co. KG am 20. August 2009 seine<br />

neue 33-MN-Strangpresse in Betrieb genommen. Mit <strong>de</strong>r<br />

von <strong>de</strong>m spanischen Ausrüster GIA gelieferten Presse will<br />

Gerhardi seine Profilproduktion bis 2013 auf rund 13.000<br />

Tonnen verdoppeln.<br />

Der NRW-Lan<strong>de</strong>sminister für Arbeit, Gesundheit und<br />

Soziales, Karl-Josef Laumann, begrüßte das „klare Ja“ zum<br />

Standort Lü<strong>de</strong>nscheid und die mutige Investition in die Zukunft.<br />

Geschäftsführer Christoph Deiters machte <strong>de</strong>utlich:<br />

„Die neue Strangpresse braucht Futter und ich möchte Sie,<br />

die Kun<strong>de</strong>n, bitten, sie mit Aufträgen zu füttern.“ Betriebsrat<br />

Martin Eickbaum ergänzte in seinem Grußwort: „Und wenn<br />

Sie, die Gäste, die Anlage gleich sehen – ich kann Ihnen<br />

sagen: Das ist schon ein Hammer.“<br />

Offizielle Inbetriebnahme <strong>de</strong>r neuen Gerhardi-Strangpresse durch<br />

<strong>de</strong>n NRW-Arbeitsminister Karl-Josef Laumann (2.v.l.). Im Vor<strong>de</strong>rgrund<br />

Geschäftsführer Christoph Deiters sowie Stephanie Hueck aus<br />

<strong>de</strong>m Gesellschafterkreis von Gerhardi <strong>Alu</strong>technik.<br />

Gesamtansicht <strong>de</strong>r 33-MN-Strangpresse<br />

Fotos: ALUMINIUM<br />

ALUMINIUM · 9/2009

European <strong>Alu</strong>minium Congress, 23 / 24 Nov 2009, Düsseldorf, Germany<br />

<strong>Alu</strong>minium Automotive Applications<br />

<strong>Alu</strong>minium has become an indispensable<br />

material in automobiles: today,<br />

castings for engine blocks, cylin<strong>de</strong>r<br />

heads and gearbox casings as well as<br />

structural components in the body<br />

area are state of the art. But semi-finished<br />

products in the form of sheet,<br />

extru<strong>de</strong>d profiles and forgings are also<br />

increasingly finding use in vehicles:<br />

for example, as body sheet and crashrelevant<br />

components such as bumper<br />

crossbeams or longitudinal chassis<br />

beams. Against this background the<br />

German tra<strong>de</strong> association GDA, Düsseldorf,<br />

is organising the European<br />

<strong>Alu</strong>minium Congress titled ‘<strong>Alu</strong>minium<br />

Automotive Applications – Material<br />

for Lightweight Construction and<br />

<strong>Alu</strong>minium jumps<br />

over UsD2,000 hurdle<br />

A lack of aluminium combined with<br />

stronger <strong>de</strong>mand from carmakers has<br />

pushed up prices of the metal, even<br />

though stocks in LME warehouses are<br />

at record highs. <strong>Alu</strong>minium breached<br />

the USD1,800/t threshold in July, a<br />

level last seen in November 2008,<br />

and even jumped over the USD2,000/<br />

t hurdle in early August. The i<strong>de</strong>a of<br />

shortages may seem odd at first glance,<br />

but a close inspection reveals that a<br />

lot of the 4.5m tonnes of aluminium<br />

stored in LME warehouses is tied up<br />

in <strong>de</strong>als to release cash for producers.<br />

That <strong>de</strong>mand could come from the car<br />

industry, which has help from government<br />

stimuli to junk old cars for new<br />

cars, and is gradually reviving after<br />

months of collapsing sales.<br />

Lack of material is already being<br />

reflected in premiums paid for physical<br />

material over futures contracts.<br />

In June, Japanese primary aluminium<br />

consumers agreed to a 30 percent<br />

hike in premiums for the current<br />

quarter. In Europe, the premium has<br />

risen to USD65 a tonne compared<br />

with USD10 in March. About 70 percent<br />

of the stocks in LME warehouses<br />

(3.15m tonnes) is thought to be tied up<br />

in financing <strong>de</strong>als until May 2010.<br />

paw<br />

ALUMINIUM · 9/2009<br />

Design’ from 23 to 24 November 2009.<br />

At the congress, the various applications<br />

of aluminium currently being<br />

used in motor cars will be presented.<br />

Moreover, top-class representatives<br />

from the car and aluminium industry<br />

and from universities will present and<br />

discuss currently used and far-sighted<br />

innovative solutions.<br />

Further information as well as various<br />

registration forms can be found<br />

on the <strong>special</strong> congress <strong>web</strong>site at<br />

www.aluminium-congress.com.<br />

Contact:<br />

Anncathrin Wener, GDA<br />

Tel: +49 211 4796 282<br />

anncathrin.wener@aluinfo.<strong>de</strong><br />

YO U R PA R T N E R F O R T E C H N O L O G I E S<br />

BUSS ChemTech AG<br />

Hohenrainstrasse 10, CH-4133 Pratteln 1/Schweiz<br />

Tel. +41 (0) 618 256 462, Fax +41 (0) 618 256 737<br />

info@buss-ct.com<br />

www.buss-ct.com<br />

N e w s i N b r i e f<br />

KAP gets cheaper<br />

power un<strong>de</strong>r MoU<br />

Struggling Kombinat <strong>Alu</strong>minijuma<br />

Podgorica (KAP), owned by heavily in<strong>de</strong>bted<br />

Oleg Deripaska’s EN+ Group,<br />

acquired cheaper energy un<strong>de</strong>r an<br />

MoU with the Montenegrin government.<br />

The future is looking more positive<br />

for the aluminium smelter un<strong>de</strong>r<br />

the recently signed <strong>de</strong>al, which enables<br />

KAP to buy power at a cheaper rate of<br />

20.44 euros (USD28.66) MWh while<br />

the LME price is un<strong>de</strong>r USD1,700 per<br />

tonne. The Montenegrin government<br />

sold KAP to EN+ Group in June 2005.<br />

In return the government would provi<strong>de</strong><br />

KAP with 135m euros in loan<br />

guarantees which would be used to<br />

pay its <strong>de</strong>bts and go towards working<br />

capital at the plant. paw<br />

SUCCESS IS BASED ON COLLABORATION<br />

USE BCT TECHNOLOGY<br />

TO INCREASE<br />

Profi t<br />

Productivity<br />

Reliability<br />

Flexibility<br />

BCT Preheater<br />

BCT Paste Knea<strong>de</strong>r<br />

BCT Cooler<br />

Ano<strong>de</strong> Press<br />

Green Ano<strong>de</strong> Plant<br />

Pitch Melting Plant<br />

Coke Processing Plant<br />

HTM Plant<br />

We maintain proactive cooperation to fulfil your requirements in or<strong>de</strong>r to build your project successfully.<br />

We are your responsible partner with the realisation of entire ano<strong>de</strong> plants from raw material to formed ano<strong>de</strong>s,<br />

as well as the supply of key equipment.<br />

We are committed to excellence to ensure you a reliable and efficient plant performance. Whenever, wherever<br />

supported by our service team.

w i r t s C h A F t<br />

10 ALUMINIUM · 9/2009

ALUMINIUM 2010<br />

8 th World Tra<strong>de</strong> Fair & Conference<br />

Weltweit wichtigster Treffpunkt für <strong>Alu</strong>minium<br />

Innovationen | Produkte | Technologien<br />

I<strong>de</strong>en | Anwendungen | Networking<br />

14. - 16. September, Messe Essen<br />

www.aluminium-messe.com<br />

Organiser: Institutional Patron: Partner:

w i r t s C h A F t<br />

Produktionsdaten <strong>de</strong>r <strong>de</strong>utschen <strong>Alu</strong>miniumindustrie<br />

Primäraluminium Sekundäraluminium Walzprodukte > 0,2 mm Press- & Ziehprodukte**<br />

Produktion<br />

(in 1.000 t)<br />

+/in<br />

% *<br />

Produktion<br />

(in 1.000 t)<br />

+/-<br />

in % *<br />

Produktion<br />

(in 1.000 t)<br />

+/in<br />

% *<br />

Produktion<br />

(in 1.000 t)<br />

Jun 50,8 9,2 68,4 -8,2 164,2 -0,3 53,6 3,7<br />

Jul 52,1 7,0 62,5 -14,4 166,7 -0,2 53,5 0,4<br />

+/in<br />

% *<br />

Aug 51,8 5,8 49,4 -24,6 147,2 -10,6 49,5 -3,9<br />

Sep 49,9 6,2 61,9 -13,7 157,7 0,6 51,6 2,8<br />

Okt 51,2 2,0 57,9 -23,9 152,7 -10,6 50,4 -9,0<br />

Nov 47,2 -5,0 48,1 -35,8 123,4 -20,8 40,4 -24,8<br />

Dez 44,8 -14,1 28,8 -49,7 90,7 -23,8 23,2 -25,0<br />

Jan 40,6 -23,1 40,3 -43,3 108,6 -29,6 34,4 -33,2<br />

Feb 33,9 -31,3 36,7 -47,0 117,1 -26,5 31,8 -40,1<br />

Mrz 27,5 -47,7 45,6 -29,0 133,2 -19,9 33,0 -31,9<br />

Apr 17,5 -65,5 40,3 -45,6 121,3 -30,8 33,1 -40,1<br />

Mai 17,5 -66,8 45,9 -29,7 120,0 -24,6 33,6 -29,1<br />

Jun 18,2 -64,2 48,8 -28,7 135,8 -17,3 37,5 -30,1<br />

* gegenüber <strong>de</strong>m Vorjahresmonat, ** Stangen, Profi le, Rohre; Mitteilung <strong>de</strong>s Gesamtverban<strong>de</strong>s <strong>de</strong>r <strong>Alu</strong>miniumindustrie (GDA), Düsseldorf<br />

Primäraluminium<br />

walzprodukte > 0,2 mm<br />

sekundäraluminium<br />

Press- und Ziehprodukte<br />

12 ALUMINIUM · 9/2009

CELL TECHNOLOGY

Rio Tinto e c o n o m i c s<br />

The curse of globalisation – must we expect crises in<br />

the aluminium industry that are more abrupt in future?<br />

B.G. Rüttimann, Singen; U.P. Fischer, Zollikerberg<br />

The increasing disintegration of value chains and co-operation that has its branches worldwi<strong>de</strong> obstruct<br />

the view of real aggregate <strong>de</strong>mand …<br />

Economic cycles are experiencing<br />

more frequent and more pronounced<br />

fluctuations in all sectors.<br />

The economic system is swinging<br />

from massive over-<strong>de</strong>mand directly<br />

into a severe sales crisis. Moreover,<br />

even experts appear to be<br />

surprised by such extreme swings.<br />

Are managers blind? No, they are<br />

merely looking at the wrong types<br />

of <strong>de</strong>mand, namely the local <strong>de</strong>mand<br />

that has been ma<strong>de</strong> visible<br />

for them, which today differs from<br />

the real aggregate <strong>de</strong>mand significantly<br />

more than it did in the<br />

past. The reason for this lies in the<br />

increasing disintegration of value<br />

chains and globally networked cooperation.<br />

These trends obstruct<br />

the view of the real aggregate<br />

<strong>de</strong>mand. Essentially each stage of<br />

industry concentrates on its direct<br />

competitors, customers or suppliers<br />

and not on the value chain as<br />

a whole. This is a strategic error.<br />

Why does the mining giant Rio Tinto<br />

only discover in November 2008<br />

that its sales of raw materials for the<br />

whole of 2008 will be ten percent<br />

less than expectations? Why didn’t<br />

Arcelor Mittal or<strong>de</strong>r a single tonne of<br />

iron ore from Vale between October<br />

2008 and March 2009? Why is Dow<br />

Chemicals temporarily closing a third<br />

of all of its production facilities? Why<br />

are Rieter and GF cutting shipments<br />

of their products to the car industry<br />

by 50 percent practically overnight?<br />

Why are Chinese ports sud<strong>de</strong>nly full<br />

of iron ore carriers and American<br />

ports full to overflowing with vehicles<br />

from BMW and Merce<strong>de</strong>s? In or<strong>de</strong>r<br />

to answer these questions one has to<br />

analyse more closely the global value<br />

chains in these sectors and above all<br />

the changes they have un<strong>de</strong>rgone as a<br />

result of globalisation since the beginning<br />

of the 1990s.<br />

The strategy of unlimited growth<br />

Starting in the 1960s, our industrial<br />

system has experienced continual<br />

growth. Demand for all types of consumer<br />

goods far excee<strong>de</strong>d supply;<br />

during this period, production and<br />

supply was easy. Markets were, to a<br />

large extent, local and<br />

in part closed. Unemployment<br />

was practically<br />

unheard of. By<br />

the 1980s at the latest,<br />

this imbalance between<br />

supply and <strong>de</strong>mand had<br />

shifted in the <strong>de</strong>veloped<br />

countries and no longer<br />

favoured producers;<br />

market segmentation<br />

and response to specific<br />

customer <strong>de</strong>mands<br />

were called for in or<strong>de</strong>r<br />

to counter increased<br />

competition.<br />

The end of the Cold<br />

War and the opening<br />

up of eastern Europe<br />

brought new opportunities<br />

and risks after 1990:<br />

not only was the market<br />

expan<strong>de</strong>d by over 100<br />

million potential new customers, there<br />

was additional competitive pressure<br />

with very favourable production costs<br />

in the eastern European countries.<br />

The globalisation in the West that took<br />

place at the same time and allowed<br />

companies to pursue new markets in<br />

the rapidly growing economies ma<strong>de</strong><br />

it possible for companies to continue<br />

with their growth-oriented business<br />

strategies. The paradigm of unlimited<br />

growth was still embed<strong>de</strong>d in the<br />

minds of managers – also urged on by<br />

short term oriented investors luring<br />

the managers with excessive bonuses<br />

(and salaries). These compensation<br />

packages are very strongly <strong>de</strong>pen<strong>de</strong>nt<br />

on the size of the companies. In<br />

the meantime, there have been fundamental<br />

changes in the structure of the<br />

value chain, abetted not least by low<br />

transport costs and advanced means<br />

of telecommunication: a network<br />

of suppliers and sub-suppliers with<br />

branches worldwi<strong>de</strong> is now striving<br />

– to a large extent in an uncoordinated<br />

manner – to achieve a supposed cost<br />

optimum within the value chain.<br />

There began a parallel race to cap-<br />

14 ALUMINIUM · 9/2009

ture the new markets (market and cost<br />

lea<strong>de</strong>rship) while at the same time securing<br />

existing markets – directly by<br />

enormous investments in increasing<br />

capacity and indirectly by optimising<br />

capacity by means of mergers and<br />

takeovers, and spurred on by the megalomania<br />

of the managers. This strategy<br />

aimed at unlimited growth was<br />

financed by readily available liquidity<br />

and low interest rates. The target markets<br />

both for expansion of production<br />

capacity and increased turnover were<br />

mostly the upcoming BRIC countries,<br />

but in addition to Russia there were<br />

also other eastern European countries<br />

with favourable labour costs.<br />

Unfortunately, all competitors had<br />

the same i<strong>de</strong>a, that is to say the same<br />

business mo<strong>de</strong>l. The managers appear<br />

not to want to think about where this<br />

might lead. A simple calculation of<br />

the additional overall capacities and<br />

the real growth would reveal the resultant<br />

imbalance in the market. Furthermore,<br />

the company takeovers and<br />

mergers have not only overstrained<br />

the organisations but also completely<br />

ALUMINIUM · 9/2009<br />

ruined healthy balance sheets – we<br />

are now seeing the results. A lack of<br />

farsightedness and ina<strong>de</strong>quate systemic<br />

thinking? Not only that but also<br />

a sizeable portion of naivety and the<br />

lack of courage to prepare a Plan B in<br />

case there is a period of bad weather<br />

and to present it to the sharehol<strong>de</strong>rs.<br />

But this is precisely what responsible<br />

management is all about.<br />

The great disenchantment<br />

What happens now when there is a<br />

small fall in <strong>de</strong>mand? Distracted by<br />

increasing turnover and blin<strong>de</strong>d by<br />

extrapolated business plans based<br />

on wrong assumptions, the managers<br />

sud<strong>de</strong>nly and astonishingly discover<br />

that, oops, they are producing too<br />

much – supply is significantly greater<br />

than the real <strong>de</strong>mand. It is interesting<br />

that this realisation was first triggered<br />

by the American subprime crisis and<br />

the overheated economy subsequently<br />

collapsed like a house of cards.<br />

And it gets even worse because<br />

prices also go into free fall as a result<br />

e c o n o m i c s<br />

…making it particularly difficult for industries<br />

<strong>de</strong>tached from the end markets …<br />

of overcapacities, higher fixed costs<br />

and lower marginal costs. The effect<br />

of the fall in prices is thus significantly<br />

more serious than the reduced quantity<br />

because it brings the potential<br />

competitiveness of the company into<br />

question – there are indications<br />

EXTRUSION - DIECASTING - FOUNDRY - ROLLING - FINISHING - MACHINING - WELDING - RECYCLING<br />

metef-foun<strong>de</strong>q<br />

14-17 April 2010<br />

Garda Exhibition Centre Montichiari Brescia Italy<br />

no. 1 metal expo in the world<br />

INTERNATIONAL<br />

ALUMINIUM EXHIBITION<br />

8 th EDITION<br />

Two events one great international<br />

appointment in constant growth:<br />

a unique opportunity to get together<br />

and do business<br />

Organizing Secretariat: EDIMET SPA,<br />

via Brescia 117 25018 Montichiari (BS) Italy<br />

Ph. +39 030 9981045 Fax +39 030 9981055<br />

info@metef.com<br />

INTERNATIONAL<br />

FOUNDRY EQUIPMENT EXHIBITION<br />

5 th EDITION<br />

Supporters:<br />

AIB - AIFM - AIM - AITAL - AMAFOND - ASSOFOND<br />

ASSOMET - CCIAA BS - CEMAFON - CIAL - EAA - ESTAL<br />

FACE - FEDERFINITURA - IIS - OEA - QUALITAL - UNCSAAL<br />

www.metef.com<br />

adnord.it ➝<br />

15<br />

Vimetco

e c o n o m i c s<br />

of trouble ahead. The current crisis is<br />

far more pronounced than the consequences<br />

of the dotcom bubble bursting<br />

in 2000.<br />

What has happened in the past few<br />

months is a consequence of the wi<strong>de</strong>ly<br />

branched global value chain. The supposedly<br />

strong increase in turnover is<br />

mainly due to an ever-longer ‘pipeline’<br />

(see also: Dynamics of the ‘pipeline<br />

filling’ effect in the aluminium semis<br />

industry, ALUMINIUM, 5/2001, p.<br />

336ff). This building up of an intermediate<br />

stock, which was even strongly<br />

supported by increasing prices for<br />

raw materials, came to an abrupt<br />

end and was sud<strong>de</strong>nly replaced by<br />

<strong>de</strong>stocking. Thus as the aggregate <strong>de</strong>mand<br />

fell, the producing companies<br />

were immediately affected – and the<br />

more so the further they were from<br />

the end market because the downstream<br />

<strong>de</strong>mand was immediately met<br />

by the well-filled ‘pipeline’.<br />

In such a situation, an attempt<br />

is also ma<strong>de</strong> to compensate for<br />

liquidity losses resulting from<br />

reduced operative income by<br />

further cutbacks in stocks. In the<br />

present crisis, this phenomenon<br />

has increased drastically as a<br />

result of the financing of the net<br />

working capital becoming ever<br />

more difficult or even impossible<br />

because of the restrictions on<br />

giving credit. If the fall in production<br />

is unduly large compared<br />

with a company’s fixed costs,<br />

restructuring and redundancies<br />

are inevitable. If the abrupt<br />

cut-back in production resulting<br />

from the emptying of the ‘supply<br />

chain’ is also superimposed on<br />

possible interest and capital repayments<br />

for short-sighted purchases<br />

of companies, it is no longer possible<br />

to rule out bankruptcies. And all of<br />

this because one has lost sight along<br />

the value chain of the end market.<br />

The question as to whether state aid<br />

and <strong>de</strong>mand-stimulating spending<br />

programmes should be carried out<br />

at the taxpayer’s expense is another<br />

problem in the making.<br />

And nothing learned…?<br />

If we fail to learn from this, we can<br />

paraphrase German dramatist Bertolt<br />

Brecht and say, “And when the whole<br />

shebang is over, it will start from the<br />

beginning again.” As soon as the pipeline<br />

of intermediate stock is empty,<br />

the aggregate <strong>de</strong>mand will again work<br />

its way along the value chain via the<br />

components to the semis and finally<br />

through to the raw materials suppliers.<br />

The pipeline is very long so consi<strong>de</strong>rable<br />

lead times are necessary before<br />

material reaches the final seller. That<br />

is why we are already hearing cries of<br />

“Can’t you supply it tomorrow? Where<br />

are the goods, I need them immediately?”<br />

reverberating today ... and have<br />

not learned anything. There are unpleasant<br />

forms of feedback from dynamic<br />

systems that we gladly ignore.<br />

Actually, this phenomenon is known<br />

as the Forrester–Burbidge effect and<br />

was already being mo<strong>de</strong>lled 40 years<br />

ago on a small scale (using simple value<br />

chains). The time it takes to pass<br />

through the production stage means<br />

the effects on the stock quantities are<br />

limited to something of the or<strong>de</strong>r of<br />

several weeks or months by. Supposedly<br />

skilful negotiating on the part<br />

of the purchaser as a result of large<br />

quantity discounts exaggerates this<br />

effect still further. Everyone suboptimises<br />

his area and thus even damages<br />

the others by thinking lean. On<br />

top of the globalisation effects of a<br />

broadly branched value chain (which<br />

benefits from cheap production locations<br />

in far away places) there are the<br />

long transport times, in other words a<br />

warehouse that is on the move.<br />

If we also take into account the<br />

increased investment activities on a<br />

global scale for installing additional<br />

production capacities, one recognises<br />

the dangerous multiplier again,<br />

but on a large scale. The throughput<br />

times for investments to expand capacity<br />

and open up markets – from<br />

the instant a <strong>de</strong>cision is ma<strong>de</strong>, via the<br />

planning through to commissioning<br />

– is measured on a timescale of years.<br />

Whether the new capacities come on<br />

stream when the economic cycle is<br />

on a downward slope instead of on<br />

an upward one is to a large extent<br />

random. It is paradoxical that the <strong>de</strong>cision<br />

to create new capacities is usually<br />

based on the maximum amplitu<strong>de</strong><br />

of the swing, which far exceeds the aggregate<br />

<strong>de</strong>mand. The consequence is<br />

expensive overcapacity, which in the<br />

worst case is subsidised with taxpay-<br />

…to react in good time to imbalances in the real economy<br />

ers’ money, and later on has to be reorganised<br />

again using taxpayers’ money.<br />

The <strong>de</strong>struction of vertically integrated<br />

industrial concerns that can<br />

actually see the end market and their<br />

replacement by companies <strong>special</strong>ising<br />

in a single stage of the value chain,<br />

mostly accompanied by horizontal<br />

mergers, is particularly apparent in<br />

mature industries (see also: Which<br />

globalisation for the aluminium industry?,<br />

ALUMINIUM, Part I in 1-<br />

2/2008, p. 16ff, Part II in 3/2008, p.<br />

16ff). The prospects have probably<br />

not improved.<br />

16 ALUMINIUM · 9/2009<br />

Norsk Hydro

What can be done?<br />

The main problem is the distorted perception of<br />

the actual aggregate <strong>de</strong>mand of the individual<br />

stages of the value chain. The momentum of the<br />

value chain, which is influenced by systemic<br />

feedback not directly linked to the actual aggregate<br />

<strong>de</strong>mand, dominates more and more the further<br />

one gets from the end market. Three major,<br />

interrelated approaches to supply-chain management<br />

are necessary:<br />

• Firstly, a shortening of the value chain by means<br />

of integration using an exchange of information<br />

and a reduction in the throughput time using lean<br />

techniques. In general, the lean approach, which<br />

means eliminating every possible source of wastage,<br />

will become even more important in future.<br />

The result will be a smaller amplitu<strong>de</strong> with faster<br />

reaction time.<br />

• Secondly, the reduced amplitu<strong>de</strong> will allow<br />

better planning of the necessary production capacity,<br />

which is based on the real aggregate <strong>de</strong>mand.<br />

This will not eliminate the expansion of<br />

overcapacities but it will at least reduce it.<br />

• Thirdly, taking all value chains into account<br />

with which one is in competition, instead of only<br />

one’s own stage. This applies to existing capacities<br />

as well as to planned extensions.<br />

In addition, real-economy planning is necessary<br />

in or<strong>de</strong>r to avoid the serious socio-economic<br />

consequences that we are currently experiencing.<br />

Now this is consistent with the i<strong>de</strong>al world<br />

we know from theoretical books. In practice, this<br />

means that the mo<strong>de</strong>lling of scenarios should not<br />

remain an aca<strong>de</strong>mic exercise and supervisory<br />

boards should insist on planning based facts;<br />

some sharehol<strong>de</strong>rs (true company owners with<br />

social responsibility) and the employees will be<br />

grateful. The other sharehol<strong>de</strong>rs (pure speculators)<br />

on the other hand will probably view the current<br />

crisis more as an opportunity to again get<br />

involved in the stock exchange in a big way. New<br />

opportunity for the one and possible unemployment<br />

for the other, who can actually do nothing<br />

for the mistakes of managers.<br />

Authors<br />

Bruno G. Rüttimann, Dr. Ing. MBA, studied at the Polytechnic<br />

Institute in Milan and the Bocconi School of<br />

Economics. As a Master Black Belt in Lean Six Sigma<br />

he is introducing Continuous Improvement techniques<br />

at Alcan Engineered Products. He is the author of Mo<strong>de</strong>ling<br />

Economic Globalization, Monsenstein & Vannerdat,<br />

2006.<br />

Urs P. Fischer, lic. rer. pol, studied Economics at the<br />

University of Bern. He worked for many years in various<br />

financial positions and as business unit presi<strong>de</strong>nt at<br />

Alcan/<strong>Alu</strong>suisse and is now an advisor to the managements<br />

of international groups. He is the owner of the<br />

management consultancy firm Lean Solution.<br />

ALUMINIUM · 9/2009<br />

��������<br />

������������������<br />

�������������������������<br />

�������������������������<br />

���������������������<br />

e c o n o m i c s<br />

������������������<br />

�� �����������������������<br />

�������������������������������������������������������<br />

��������������������������������������������������������<br />

����������������������������������������������������<br />

���������������������������������������������������<br />

��������������������������������������������������<br />

�������������������������������������������������������<br />

�������������������������������������������������<br />

�������������������������������<br />

������������������������������������������<br />

���������

W i R T s c H A F T<br />

Hilfsmaßnahmen für energieintensive Betriebe in Vorbereitung<br />

Seit Jahren beklagt die <strong>de</strong>utsche<br />

NE-Metallindustrie die<br />

hohen heimischen Strompreise<br />

und verweist darauf, dass die<br />

europäischen Wettbewerber mit<br />

günstigen Industriestrompreisen<br />

versorgt wer<strong>de</strong>n. Mehr als einmal<br />

ist von führen<strong>de</strong>n Branchen- und<br />

Unternehmensvertretern darauf<br />

hingewiesen wor<strong>de</strong>n, dass die<br />

energieintensiven Betriebe diese<br />

Kostennachteile auf Dauer nicht<br />

tragen können. Inzwischen scheint<br />

auch in Berlin und Brüssel die<br />

Einsicht zu wachsen, dass dieser<br />

Entwicklung entgegengesteuert<br />

wer<strong>de</strong>n muss. Mit kurz-, mittel-<br />

und langfristigen Maßnahmen soll<br />

die Position <strong>de</strong>r energieintensiven<br />

Betriebe in Deutschland nun gestärkt<br />

wer<strong>de</strong>n.<br />

Heinz-Peter Schlüter, Inhaber und<br />

Aufsichtsratsvorsitzen<strong>de</strong>r <strong>de</strong>r Trimet<br />

<strong>Alu</strong>minium AG zeigte sich in einem<br />

Gespräch mit Journalisten am Hüttenstandort<br />

Essen erfreut darüber,<br />

dass die Bun<strong>de</strong>sregierung konkrete<br />

Schritte eingeleitet hat, um <strong>de</strong>n Erhalt<br />

<strong>de</strong>r klimaschonend produzieren<strong>de</strong>n<br />

<strong>Alu</strong>miniumhütten in Deutschland<br />

zu sichern. Der dazu aufgelegte dreigliedrige<br />

Maßnahmenplan wur<strong>de</strong><br />

vom energiepolitischen Sprecher <strong>de</strong>r<br />

SPD-Bun<strong>de</strong>stagsfraktion Rolf Hempelmann<br />

erläutert, <strong>de</strong>r das laufen<strong>de</strong><br />

Verfahren wesentlich vorangetrieben<br />

und mit gestaltet hat. Der Plan umfasst<br />

eine<br />

• Soforthilfe für 2009 über einen<br />

Son<strong>de</strong>rfonds im Konjunkturpaket 2<br />

• Überbrückungslösung für die Jahre<br />

2010 bis 2012<br />

Planung, Konstruktion und Ausführung<br />

von Industrieofenanlagen<br />

Konstantinstraße 1a<br />

41238 Mönchengladbach<br />

Telefon +49(0)2166/987990<br />

Telefax +49(0)2166/987996<br />

E-mail info@inotherm-gmbh.<strong>de</strong><br />

Internet www.inotherm-gmbh.<strong>de</strong><br />

Nehmen zu <strong>de</strong>n geplanten Hilfsmaßnahmen für energieintensive Unternehmen Stellung,<br />

v.l.n.r.: Heinz-Peter Schlüter, Rolf Hempelmann (MdB), Heribert Hauck<br />

• Befreiung <strong>de</strong>r stromintensiven Unternehmen<br />

von <strong>de</strong>n CO 2 -Kosten im<br />

Strom im Rahmen <strong>de</strong>r Emissionshan<strong>de</strong>lsrichtlinie<br />

für die 3. Han<strong>de</strong>lsperio<strong>de</strong><br />

ab 2013.<br />

Zur Stützung <strong>de</strong>r stromintensiven<br />

Unternehmen <strong>de</strong>r NE-Metallproduktion<br />

hat die Bun<strong>de</strong>sregierung für das<br />

zweite Halbjahr 2009 einen För<strong>de</strong>rbetrag<br />

in Höhe von 40 Mio. Euro bereitgestellt.<br />

Das Bun<strong>de</strong>swirtschaftsministerium<br />

hat eine Richtlinie zu<br />

dieser För<strong>de</strong>rmaßnahme erarbeitet,<br />

die En<strong>de</strong> Juli zur Notifizierung nach<br />

Brüssel ging. Hempelmann zeigte sich<br />

überzeugt, dass Brüssel dieser Regelung<br />

zustimmen wird.<br />

Bemessungsgrundlage für die<br />

Hilfsgel<strong>de</strong>r ist <strong>de</strong>r für die Elektrolyse<br />

benötigte Strom <strong>de</strong>s <strong>de</strong>m Antragsmonat<br />

jeweils vorvergangenen Monats.<br />

Dies kompensiert circa die Hälfte <strong>de</strong>r<br />

CO 2 -Kosten im Strom. Bei <strong>de</strong>r Trimet<br />

schlugen diese Kosten im letzten<br />

Geschäftsjahr mit insgesamt 33 Mio.<br />

Euro zu Buche, das Unternehmen erhofft<br />

sich daher rund 16,5 Mio. Euro<br />

aus <strong>de</strong>m Fonds.<br />

Als Überbrückungslösung bis 2012<br />

wird eine Vergütung abschaltbarer<br />

n Rolling mills cold/hot<br />

n Roll grinding machines<br />

n Continuous casters<br />

n Levellers/straighteners<br />

n Drawing machines<br />

We purchase and supply:<br />

n Slitting lines<br />

n Cut-to-length lines<br />

n Coilers<br />

n Coil carriages<br />

n Rollformers<br />

Leistung zur Sicherung <strong>de</strong>r Netzstabilität<br />

angestrebt. Hierzu wur<strong>de</strong><br />

eine Studie in Auftrag gegeben, die<br />

die technisch-wirtschaftlichen sowie<br />

rechtlichen Rahmenbedingungen zur<br />

Umsetzung dieser Lösung untersucht<br />

und substanziiert. Alternativ bzw. ergänzend<br />

hierzu hat die Bun<strong>de</strong>sregierung<br />

die Fortsetzung <strong>de</strong>r För<strong>de</strong>rung<br />

über Haushaltsmittel für <strong>de</strong>n Zeitraum<br />

2010 bis 2012 zugesagt.<br />

Heribert Hauck, Leiter <strong>de</strong>s Trimet-Ressorts<br />

Energiewirtschaft, verwies<br />

darauf, dass <strong>Alu</strong>miniumhütten<br />

durch die gleichmäßige Abnahme von<br />

Grundlaststrom wesentlich zur Netzstabilität<br />

beitragen und <strong>de</strong>n Netzbetreibern<br />

auf diese Weise die Vorhaltung<br />

teurer Regelenergie ersparen.<br />

Eine Ausgleichszahlung dafür erfolge<br />

jedoch nicht, sodass heute allein die<br />

Stromkonzerne von <strong>de</strong>n so vermie<strong>de</strong>nen<br />

Kosten profitierten.<br />

Darüber hinaus wur<strong>de</strong> im Dezember<br />

2008 in Brüssel die Emissionshan<strong>de</strong>lsrichtlinie<br />

3 beschlossen, die<br />

für stromintensive Unternehmen, die<br />

<strong>de</strong>m sogenannten Carbon-Leakage-<br />

Risiko unterliegen, eine Befreiung von<br />

<strong>de</strong>n direkten, aber auch indirekten,<br />

Please ask for our sales list!<br />

n Tube welding machines<br />

n Extrusion presses<br />

n Joining presses<br />

n Packing lines for strips<br />

COILTEC Maschinenvertriebs GmbH · Silberkaute 4 · 57258 Freu<strong>de</strong>nberg<br />

Phone +49 (0) 2734/271190 · Fax +49 (0) 2734/271195<br />

www.coiltec.<strong>de</strong> · email: info@coiltec.<strong>de</strong><br />

18 ALUMINIUM · 9/2009<br />

Jürgen Clemens

im Strom eingepreisten CO2-Kosten erlaubt. Die Modalitäten zur Befreiung<br />

insbeson<strong>de</strong>re von <strong>de</strong>n indirekten<br />

CO2-Kosten im Strom müssen jedoch<br />

noch präzisiert und in nationales<br />

Recht umgesetzt wer<strong>de</strong>n, damit diese<br />

Möglichkeit zu einer belastbaren Planungsgrundlage<br />

wird.<br />

Schlüter und Hauck betonten,<br />

dass eine vollständige Befreiung von<br />

<strong>de</strong>n im Strompreis nachgewiesenen<br />

CO2-Kosten notwendig sei. Bei<strong>de</strong><br />

verwiesen darauf, dass die Preisbildung<br />

bei Strom nach <strong>de</strong>r sogenann-<br />

ten Merit Or<strong>de</strong>r erfolgt,<br />

das heißt nach<br />

<strong>de</strong>m letzten, teuren<br />

Kraftwerk, das für<br />

ein schnelles, flexibles<br />

Angebot in <strong>de</strong>r<br />

Spitzenlast sorgt.<br />

Unternehmen wie<br />

Trimet brauchten<br />

als Grundlastabnehmer<br />

jedoch keine<br />

<strong>de</strong>rartige Flexibilität<br />

und seien somit<br />

auch nicht an <strong>de</strong>n<br />

damit verbun<strong>de</strong>nen<br />

höheren Kosten zu<br />

beteiligen. Industriestrompreise<br />

wie in<br />

europäischen Nachbarlän<strong>de</strong>rn<br />

nähmen<br />

dagegen Rücksicht<br />

auf eine Grundlastabnahme.<br />

Eine „flache“Stromabnahme,<br />

verbun<strong>de</strong>n mit<br />

<strong>de</strong>m möglichen Verzicht<br />

auf „primäre<br />

Regelreserve“ und<br />

die Unterstützung<br />

<strong>de</strong>r Netzstabilität<br />

„rechtfertigen substanziellIndustriestrompreise<br />

bzw.<br />

Preise mit Son<strong>de</strong>rkonditionen“<br />

auch<br />

für die heimischen<br />

e n e r g i e i n t e n s i -<br />

ven Betriebe, so<br />

Schlüter.<br />

Er betonte, dass<br />

Trimet wie alle<br />

Industriebetriebe<br />

dringend Planungssicherheit<br />

über einen<br />

längerfristigen<br />

ALUMINIUM · 9/2009<br />

Zeithorizont benötige. Dies gelte<br />

beson<strong>de</strong>rs mit Blick auf die Kun<strong>de</strong>n<br />

aus <strong>de</strong>r Automobilindustrie, die langfristige<br />

Liefer- und Preisgarantien bei<br />

<strong>de</strong>r Abnahme von <strong>Alu</strong>miniumprodukten<br />

verlangten. Die könne Trimet<br />

aber nur abgeben, „wenn wir selbst<br />

längerfristige Planungssicherheit haben.<br />

Nota bene: Planungssicherheit<br />

in <strong>de</strong>r Herstellung von <strong>Alu</strong>minium<br />

ist untrennbar verbun<strong>de</strong>n mit Planungssicherheit<br />

in <strong>de</strong>r bezahlbaren<br />

Beschaffung <strong>de</strong>s Rohstoffes Strom“,<br />

sagte Schlüter.<br />

WE MAKE SURE THAT FUTURE PROSPECTS LOOK BRIGHT.<br />

WITH SOLUTIONS FOR EVERY STANDARD.<br />

As the market lea<strong>de</strong>r for alumi -<br />

nium profi les Sapa means more<br />

than cus tomized solutions: we also<br />

supply standard products with<br />

which you can work suc cess fully<br />

long term. As a group that operates<br />

world wi<strong>de</strong> we react quickly<br />

and fl exibly, regard less of what it<br />

Sapa GmbH<br />

European Trading Business<br />

W i R T s c H A F T<br />

Trimet fährt Öfen wie<strong>de</strong>r hoch<br />

Angesichts einer inzwischen leicht<br />

erhöhten Nachfrage gegenüber <strong>de</strong>m<br />

drastischen Nachfrageeinbruch im<br />

Januar / Februar dieses Jahres und gestiegener<br />

<strong>Alu</strong>miniumpreise seit <strong>de</strong>m<br />

Tiefststand im März fährt Trimet seine<br />

Produktion von Hüttenaluminium<br />

am Standort Essen wie<strong>de</strong>r hoch. „Wir<br />

strengen uns an, dass wir im ersten<br />

Quartal 2010 wie<strong>de</strong>r voll produzieren“,<br />

sagte Schlüter.<br />

■<br />

is you need and where you need it.<br />

Together with market knowledge<br />

based on many years’ experience<br />

this makes us a strong partner<br />

with whom you can look calmly<br />

into the future. For further information<br />

go to www.sapagroup.com/<br />

europeantrading<br />

19

Abbildungen: Dr. Ing. h.c. F. Porsche AG<br />

A L U M I N I U M I M A U t o M o b I L<br />

Porsche Panamera – eine Synthese<br />

aus Sportlichkeit, Komfort und Effizienz<br />

Bereits im April 2009 ist im<br />

Porsche-Werk Leipzig die Serienproduktion<br />

<strong>de</strong>r vierten Baureihe<br />

Panamera angelaufen. In <strong>de</strong>r <strong>de</strong>rzeit<br />

mo<strong>de</strong>rnsten Automobilfabrik<br />

<strong>de</strong>r Welt montiert <strong>de</strong>r Sportwagenhersteller<br />

mit neuesten Fertigungsmetho<strong>de</strong>n<br />

<strong>de</strong>n viertürigen<br />

Gran Turismo gemeinsam mit <strong>de</strong>m<br />

Gelän<strong>de</strong>wagen Cayenne auf einer<br />

Linie. Mit <strong>de</strong>m Panamera will Porsche<br />

neue Käuferschichten aus <strong>de</strong>r<br />

Oberklasse gewinnen.<br />

Der Panamera zeichnet sich durch hohen<br />

Komfort, ein außergewöhnliches<br />

Raumangebot und extrem sportliche<br />

Fahreigenschaften bei gleichzeitig geringem<br />

Verbrauch aus. Zur Markteinführung<br />

am 12. September in Deutsch-<br />

Produktionsanlauf <strong>de</strong>s neuen Panamera<br />

Production start-up for the new Panamera<br />

land ging <strong>de</strong>r Sportwagen zunächst in<br />

drei Varianten an <strong>de</strong>n Start, die mit<br />

einem 400 PS starken V8-Saugmotor<br />

bzw. mit einem V8-Biturbo-Aggregat<br />

mit 500 PS ausgestattet sind. Die Motoren<br />

wer<strong>de</strong>n mit kraftstoffsparen<strong>de</strong>r<br />

Benzin-Direkteinspritzung angeboten.<br />

Porsche plant, über <strong>de</strong>n gesamten<br />

Lebenszyklus hinweg jährlich rund<br />

20.000 Fahrzeuge abzusetzen.<br />

Fünf technische Innovationen,<br />

die erstmals in einem Serienmo<strong>de</strong>ll<br />

<strong>de</strong>r Oberklasse eingeführt wer<strong>de</strong>n,<br />

zeichnen <strong>de</strong>n Panamera aus: darunter<br />

das erste Start-Stopp-System in<br />

Verbindung mit einem automatisch<br />

schalten<strong>de</strong>n Getriebe und die aktive<br />

Aerodynamik mit einem beim Panamera<br />

Turbo mehrdimensional verstellbaren,<br />

ausfahrbaren Heckspoiler.<br />

Das Fahrwerk verbin<strong>de</strong>t Sportlichkeit<br />

mit Komfort. In <strong>de</strong>r Grundabstimmung<br />

bietet es sehr hohen Reisekomfort,<br />

verwan<strong>de</strong>lt sich aber auf Knopfdruck<br />

dank<br />

<strong>de</strong>s aktiven<br />

D ä m p f e r s y s -<br />

tems PASM in<br />

ein fahraktives<br />

Sportfahrwerk.<br />