AL_n5_OTTOBRE_2016

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

0070-0073 4<br />

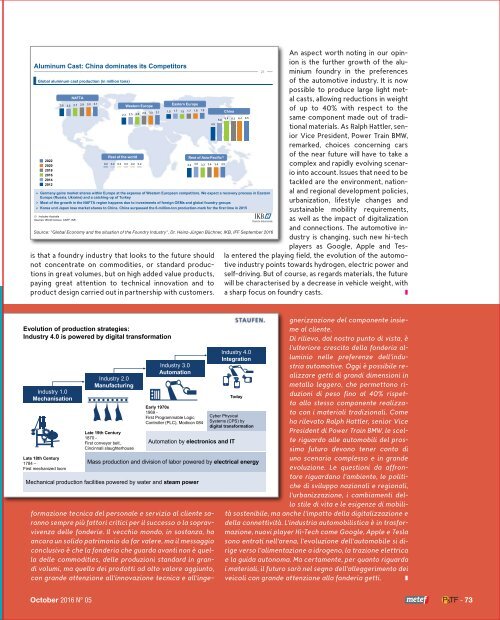

Aluminum Cast: China dominates its Competitors<br />

Global aluminum cast production (in million tons)<br />

2022<br />

2020<br />

2018<br />

<strong>2016</strong><br />

2014<br />

2012<br />

‣ Germany gains market shares within Europe at the expense of Western European competitors. We expect a recovery process in Eastern<br />

Europe (Russia, Ukraine) and a catching-up of Turkey<br />

‣ Most of the growth in the NAFTA region happens due to investments of foreign OEMs and global foundry groups<br />

‣ Korea und Japan lose market shares to China. China surpassed the 6-million-ton production-mark for the first time in 2015<br />

1) Includes Australia<br />

Sources: World Census, CAEF, IKB<br />

NAFTA<br />

2.6 2.5 2.7 2.9 3.0 3.1<br />

Western Europe<br />

Eastern Europe<br />

2.3 2.5 2.6 2.9 3.0 3.1 1.5 1.7 1.5 1.7 1.8 1.9<br />

Rest of the world<br />

0.2 0.2 0.2 0.2 0.2 0.2<br />

Rest of Asia-Pacific 1)<br />

isthatafoundryindustrythatlookstothefutureshould<br />

not concentrate on commodities, or standard productions<br />

in great volumes, but on high added value products,<br />

paying great attention to technical innovation and to<br />

product design carried out in partnership with customers.<br />

3.2<br />

4.5<br />

5.9<br />

3.6 3.3 3.4 3.4 3.5<br />

China<br />

6.4 6.3 6.4 6.5<br />

Source:"GlobalEconomyandthesituationoftheFoundryIndustry",Dr.Heinz-JürgenBüchner,IKB,IFFSeptember<strong>2016</strong><br />

23<br />

Anaspectworthnotinginouropinion<br />

is the further growth of the aluminium<br />

foundry in the preferences<br />

of the automotive industry. It is now<br />

possible to produce large light metal<br />

casts, allowing reductions in weight<br />

of up to 40% with respect to the<br />

samecomponentmadeoutoftraditional<br />

materials. As Ralph Hattler, senior<br />

Vice President, Power Train BMW,<br />

remarked, choices concerning cars<br />

of the near future will have to take a<br />

complex and rapidly evolving scenario<br />

into account. Issues that need to be<br />

tackledaretheenvironment,national<br />

and regional development policies,<br />

urbanization, lifestyle changes and<br />

sustainable mobility requirements,<br />

as well as the impact of digitalization<br />

and connections. The automotive industry<br />

is changing, such new hi-tech<br />

players as Google, Apple and Tesla<br />

entered the playing field, the evolution of the automotiveindustrypointstowardshydrogen,electricpowerand<br />

self-driving.Butofcourse,asregardsmaterials,thefuture<br />

will be characterised by a decrease in vehicle weight, with<br />

asharpfocusonfoundrycasts.<br />

❚<br />

Evolution of production strategies:<br />

Industry 4.0 is powered by digital transformation<br />

Industry 1.0<br />

Mechanisation<br />

Late 18th Century<br />

1784 –<br />

First mechanized loom<br />

Industry 2.0<br />

Manufacturing<br />

Late 19th Century<br />

1870 -<br />

First conveyor belt,<br />

Cincinnati slaughterhouse<br />

Industry 3.0<br />

Automation<br />

Early 1970s<br />

1969 -<br />

First Programmable Logic<br />

Controller (PLC), Modicon 084<br />

Cyber Physical<br />

Systems (CPS) by<br />

digital transformation<br />

Automation by electronics and IT<br />

Mass production and division of labor powered by electrical energy<br />

Mechanical production facilities powered by water and steam power<br />

Industry 4.0<br />

Integration<br />

Today<br />

formazionetecnicadelpersonaleeservizioalclientesaranno<br />

sempre più fattori critici per il successo o la sopravvivenza<br />

delle fonderie. Il vecchio mondo, in sostanza, ha<br />

ancoraunsolidopatrimoniodafarvalere,mailmessaggio<br />

conclusivo è che la fonderia che guarda avanti non è quella<br />

delle commodities, delle produzioni standard in grandi<br />

volumi, ma quella dei prodotti ad alto valore aggiunto,<br />

con grande attenzione all’innovazione tecnica e all’ingegnerizzazione<br />

del componente insieme<br />

al cliente.<br />

Dirilievo,dalnostropuntodivista,è<br />

l’ulteriore crescita della fonderia alluminio<br />

nelle preferenze dell’industria<br />

automotive. Oggi è possibile realizzare<br />

getti di grandi dimensioni in<br />

metallo leggero, che permettono riduzioni<br />

di peso fino al 40% rispetto<br />

allo stesso componente realizzato<br />

con i materiali tradizionali. Come<br />

ha rilevato Ralph Hattler, senior Vice<br />

President di Power Train BMW, le scelte<br />

riguardo alle automobili del prossimo<br />

futuro devono tener conto di<br />

uno scenario complesso e in grande<br />

evoluzione. Le questioni da affrontare<br />

riguardano l’ambiente, le politiche<br />

di sviluppo nazionali e regionali,<br />

l’urbanizzazione, i cambiamenti dellostiledivitaeleesigenzedimobili-<br />

tàsostenibile,maanchel’impattodelladigitalizzazionee<br />

della connettività. L’industria automobilistica è in trasformazione,<br />

nuovi player Hi-Tech come Google, Apple e Tesla<br />

sono entrati nell’arena, l’evoluzione dell’automobile si dirige<br />

verso l’alimentazione a idrogeno, la trazione elettrica<br />

e la guida autonoma. Ma certamente, per quanto riguarda<br />

imateriali,ilfuturosarànelsegnodell’alleggerimentodei<br />

veicoli con grande attenzione alla fonderia getti. ❚<br />

October <strong>2016</strong> N° 05<br />

- 73