AL_n5_OTTOBRE_2016

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

0078-0082 3<br />

Applications-Automotive<br />

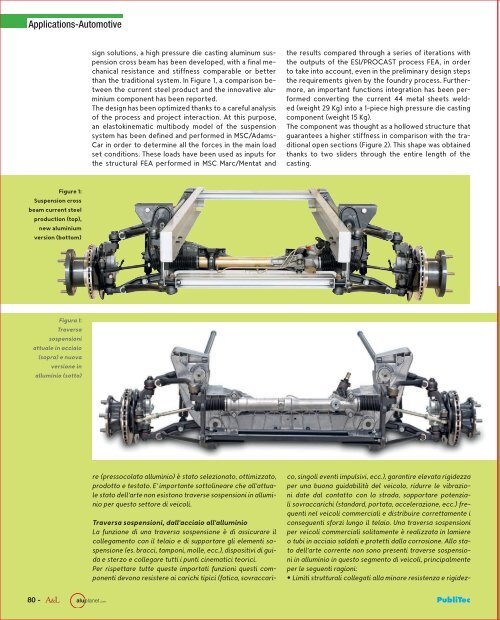

signsolutions,ahighpressurediecastingaluminumsuspension<br />

cross beam has been developed, with a final mechanical<br />

resistance and stiffness comparable or better<br />

than the traditional system. In Figure 1, a comparison between<br />

the current steel product and the innovative aluminium<br />

component has been reported.<br />

The design has been optimized thanks to a careful analysis<br />

of the process and project interaction. At this purpose,<br />

an elastokinematic multibody model of the suspension<br />

systemhasbeendefinedandperformedinMSC/Adams-<br />

Car in order to determine all the forces in the main load<br />

set conditions. These loads have been used as inputs for<br />

the structural FEA performed in MSC Marc/Mentat and<br />

the results compared through a series of iterations with<br />

the outputs of the ESI/PROCAST process FEA, in order<br />

to take into account, even in the preliminary design steps<br />

the requirements given by the foundry process. Furthermore,<br />

an important functions integration has been performed<br />

converting the current 44 metal sheets welded<br />

(weight 29 Kg) into a 1-piece high pressure die casting<br />

component(weight15Kg).<br />

Thecomponentwasthoughtasahollowedstructurethat<br />

guarantees a higher stiffness in comparison with the traditional<br />

open sections (Figure 2). This shape was obtained<br />

thanks to two sliders through the entire length of the<br />

casting.<br />

Figure 1:<br />

Suspension cross<br />

beam current steel<br />

production (top),<br />

new aluminium<br />

version (bottom)<br />

Figura 1:<br />

Traversa<br />

sospensioni<br />

attuale in acciaio<br />

(sopra) e nuova<br />

versione in<br />

alluminio (sotto)<br />

re (pressocolata alluminio) è stato selezionato, ottimizzato,<br />

prodottoetestato.E’importantesottolinearecheall’attualestatodell’artenonesistonotraversesospensioniinalluminio<br />

per questo settore di veicoli.<br />

Traversa sospensioni, dall’acciaio all’alluminio<br />

Lafunzionediunatraversasospensioneèdiassicurareil<br />

collegamentoconiltelaioedisupportareglielementisospensione<br />

(es. bracci, tamponi, molle, ecc.), dispositivi di guidaesterzoecollegaretuttiipunticinematiciteorici.<br />

Perrispettaretuttequesteimportatifunzioniquesticomponenti<br />

devono resistere ai carichi tipici (fatica, sovraccarico,singolieventiimpulsivi,ecc.),garantireelevatarigidezza<br />

perunabuonaguidabilitàdelveicolo,ridurrelevibrazioni<br />

date dal contatto con la strada, sopportare potenziali<br />

sovraccarichi (standard, portata, accelerazione, ecc.) frequentinelveicolicommercialiedistribuirecorrettamentei<br />

conseguentisforzilungoiltelaio.Unatraversasospensioni<br />

per veicoli commerciali solitamente è realizzata in lamiere<br />

otubiinacciaiosaldatieprotettidallacorrosione.Allostato<br />

dell’arte corrente non sono presenti traverse sospensioni<br />

in alluminio in questo segmento di veicoli, principalmente<br />

per le seguenti ragioni:<br />

• Limiti strutturali collegati alla minore resistenza e rigidez-<br />

80 - .com<br />

PubliTec