INVISTA EM CONHECIMENTO - Revista O Papel

INVISTA EM CONHECIMENTO - Revista O Papel

INVISTA EM CONHECIMENTO - Revista O Papel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

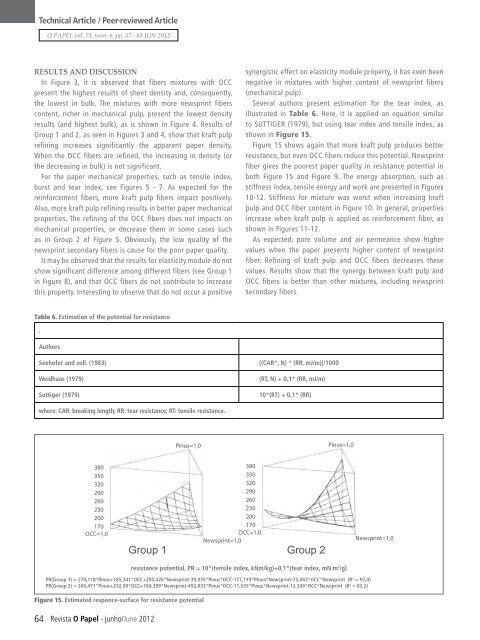

Technical Article / Peer-reviewed ArticleO PAPEL vol. 73, num. 6, pp. 57 - 65 JUN 2012RESULTS AND DISCUSSIONin figure 3, it is observed that fibers mixtures with oCCpresent the highest results of sheet density and, consequently,the lowest in bulk. the mixtures with more newsprint fiberscontent, richer in mechanical pulp, present the lowest densityresults (and highest bulk), as is shown in figure 4. results ofGroup 1 and 2, as seen in figures 3 and 4, show that kraft pulprefining increases significantly the apparent paper density.when the oCC fibers are refined, the increasing in density (orthe decreasing in bulk) is not significant.for the paper mechanical properties, such as tensile index,burst and tear index, see figures 5 - 7. as expected for thereinforcement fibers, more kraft pulp fibers impact positively.also, more kraft pulp refining results in better paper mechanicalproperties. the refining of the oCC fibers does not impacts onmechanical properties, or decrease them in some cases suchas in Group 2 of figure 5. obviously, the low quality of thenewsprint secondary fibers is cause for the poor paper quality.it may be observed that the results for elasticity module do notshow significant difference among different fibers (see Group 1in figure 8), and that oCC fibers do not contribute to increasethis property. interesting to observe that do not occur a positivesynergistic effect on elasticity module property, it has even beennegative in mixtures with higher content of newsprint fibers(mechanical pulp).several authors present estimation for the tear index, asillustrated in Table 6. here, it is applied an equation similarto suttiGer (1979), but using tear index and tensile index, asshown in Figure 15.figure 15 shows again that more kraft pulp produces betterresistance, but even oCC fibers reduce this potential. newsprintfiber gives the poorest paper quality in resistance potential inboth figure 15 and figure 9. the energy absorption, such asstiffness index, tensile energy and work are presented in figures10-12. stiffness for mixture was worst when increasing kraftpulp and oCC fiber content in figure 10. in general, propertiesincrease when kraft pulp is applied as reinforcement fiber, asshown in figures 11-12.as expected, pore volume and air permeance show highervalues when the paper presents higher content of newsprintfiber. refining of kraft pulp and oCC fibers decreases thesevalues. results show that the synergy between kraft pulp andoCC fibers is better than other mixtures, including newsprintsecondary fibers.Table 6. Estimation of the potential for resistance.AuthorsSeehofer and coll. (1983)Weidhaas (1979)Suttiger (1979)[(CAR*, N) * (RR, mJ/m)]/1000(RT, N) + 0,1* (RR, mJ/m)10*(RT) + 0,1* (RR)where: CAR: breaking length; RR: tear resistance; RT: tensile resistance.PR(Group 1) = 270,118*Pinus+185,341*OCC+200,426*Newsprint-39,935*Pinus*OCC-177,119*Pinus*Newsprint-75,043*OCC*Newsprint (R 2 = 92,4)PR(Group 2) = 345,471*Pinus+232,09*OCC+193,399*Newsprint-492,833*Pinus*OCC-11,535*Pinus*Newsprint-13,338*OCC*Newsprint (R 2 = 83,2)Figure 15. Estimated responce-surface for resistance potential64 <strong>Revista</strong> O <strong>Papel</strong> - junho/June 2012resistance potential, PR = 10*(tensile index, kNm/kg)+0,1*(tear index, mN.m 2 /g)