Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

yaşam için baskı <strong>2018</strong><br />

sense of belonging. He also demonstrated the benefits<br />

of using ferrous media for mounting to magnetic<br />

panels for quick and easy graphic change overs in<br />

retail environments. Xavier continued to review the<br />

stunning opportunities currently available using dye<br />

sub fabric to create continuous walls of seamless<br />

imagery. The key message was that every surface<br />

can be printed on. Antalis have created their ‘Antalis<br />

Interior Design Award’ which received 43,000 visitors<br />

of which 29,000 were unique and received over 300<br />

entries. Antalis also created ‘The Book’ which features<br />

the stories of the winners and the top 50 entries.<br />

Dr. Dieter Holzinger from Tiger Coatings presented<br />

their ink solutions for different décor applications.<br />

Tiger Coatings manufacture water-based UV inks<br />

for single pass printing at speeds of up to 200 linear<br />

metres per minute. These ink solutions are pinned<br />

(part cured) with UV before being exposed to near<br />

infrared energy to remove the water. Afterwards<br />

they are finally cured with mercury vapour UV. In<br />

addition, they make ceramic inks that fire at 600°C<br />

or a UV curing formulation for ceramic and glass<br />

applications on pre-treated substrates.<br />

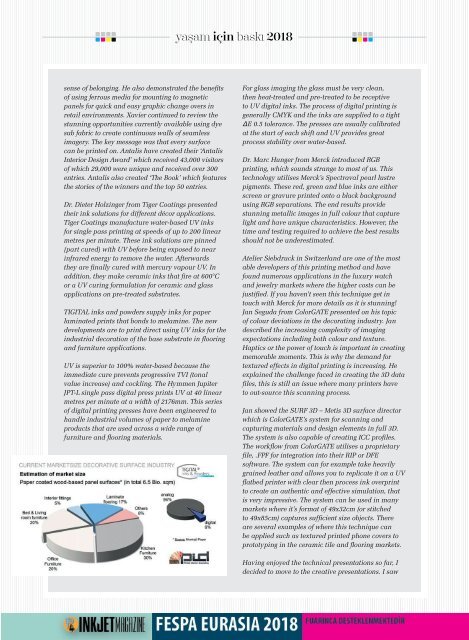

TIGITAL inks and powders supply inks for paper<br />

laminated prints that bonds to melamine. The new<br />

developments are to print direct using UV inks for the<br />

industrial decoration of the base substrate in flooring<br />

and furniture applications.<br />

UV is superior to 100% water-based because the<br />

immediate cure prevents progressive TVI (tonal<br />

value increase) and cockling. The Hymmen Jupiter<br />

JPT-L single pass digital press prints UV at 40 linear<br />

metres per minute at a width of 2176mm. This series<br />

of digital printing presses have been engineered to<br />

handle industrial volumes of paper to melamine<br />

products that are used across a wide range of<br />

furniture and flooring materials.<br />

For glass imaging the glass must be very clean,<br />

then heat-treated and pre-treated to be receptive<br />

to UV digital inks. The process of digital printing is<br />

generally CMYK and the inks are supplied to a tight<br />

ΔE 0.5 tolerance. The presses are usually calibrated<br />

at the start of each shift and UV provides great<br />

process stability over water-based.<br />

Dr. Marc Hunger from Merck introduced RGB<br />

printing, which sounds strange to most of us. This<br />

technology utilises Merck’s Spectraval pearl lustre<br />

pigments. These red, green and blue inks are either<br />

screen or gravure printed onto a black background<br />

using RGB separations. The end results provide<br />

stunning metallic images in full colour that capture<br />

light and have unique characteristics. However, the<br />

time and testing required to achieve the best results<br />

should not be underestimated.<br />

Atelier Siebdruck in Switzerland are one of the most<br />

able developers of this printing method and have<br />

found numerous applications in the luxury watch<br />

and jewelry markets where the higher costs can be<br />

justified. If you haven’t seen this technique get in<br />

touch with Merck for more details as it is stunning!<br />

Jan Seguda from ColorGATE presented on his topic<br />

of colour deviations in the decorating industry. Jan<br />

described the increasing complexity of imaging<br />

expectations including both colour and texture.<br />

Haptics or the power of touch is important in creating<br />

memorable moments. This is why the demand for<br />

textured effects in digital printing is increasing. He<br />

explained the challenge faced in creating the 3D data<br />

files, this is still an issue where many printers have<br />

to out-source this scanning process.<br />

Jan showed the SURF 3D – Metis 3D surface director<br />

which is ColorGATE’s system for scanning and<br />

capturing materials and design elements in full 3D.<br />

The system is also capable of creating ICC profiles.<br />

The workflow from ColorGATE utilises a proprietary<br />

file, .FPF for integration into their RIP or DFE<br />

software. The system can for example take heavily<br />

grained leather and allows you to replicate it on a UV<br />

flatbed printer with clear then process ink overprint<br />

to create an authentic and effective simulation, that<br />

is very impressive. The system can be used in many<br />

markets where it’s format of 49x32cm (or stitched<br />

to 49x85cm) captures sufficient size objects. There<br />

are several examples of where this technique can<br />

be applied such as textured printed phone covers to<br />

prototyping in the ceramic tile and flooring markets.<br />

Having enjoyed the technical presentations so far, I<br />

decided to move to the creative presentations. I saw