UPDATEThomas Nagel. Als man am 11. Dezember 2009 mit denMontagetätigkeiten für die Betriebshofsteuerung in PotsdamBabelsberg begann, klopfte gerade der Winter an die Tür undbrachte Schnee und Kälte mit sich. Zu diesem Zeitpunkt konntenoch niemand ahnen, dass genau dieser Schnee auch nochEnde Februar dort liegen sollte. Denn es war ja im Rückblickeiner der längsten Winter seit Jahrzehnten. Aber dieses Wetterkonnte alle Beteiligten nicht davon abhalten, die Betriebshofsteuerungpünktlich und erfolgreich in Betrieb zu nehmen.Denn, wie schon der Volksmund sagt: Es gibt kein schlechtesWetter, sondern nur falsche Kleidung.1Im Frühjahr 2009 wurde für denBetriebshof der VerkehrsbetriebePotsdam GmbH (VIP) in PostdamBabelsberg eine Erneuerung derSteuerung ausgeschrieben, welcheden Ersatz der erst 2001 inBetrieb gegangenen Alt-Steuerungvorsah.Das Stellwerk und die ausge -lagerten Stellrechner waren alsspeicherprogrammierbare Steuerung(SPS) ausgeführt. Als Stellrechnerwurden Simatic S5AG115U (SPS) eingesetzt. AlsZentralebene wurde eine SPS S7CPU 315 eingesetzt, für dieBedienung und Anzeige das BedienplatzsystemVICOS OC-11.Bedingt durch das veralteteBetriebssystem auf den PCs derLeitebene für Bedienung und Anzeige(Windows NT), der veraltetenPC-Hardware sowie der Abkündigungdiverser Hardware -komponenten (z. B. SIMATIC S5),welche eine Ersatzteilversorgungerschwerten, wurden diese fürden Kunden gravierenden Inves -titionsausgaben noch vor Endeder gewünschten Lebenszeit erforderlich.Zusätzlich war der Wunsch nachweitergehenden Funktionen vorhanden.Als Beispiel sind hier nurkurz die Erhöhung der Sicherheitfür Fahr- und Leitstellenpersonal,die Aufzeichnung der Schalthandlungen,die DCF-Zeitsynchronisationsowie die Realisierungweiterer Fahrmöglichkeitenzu nennen.Zielsetzung war hier durch eineteilweise Ersetzung der Komponentendie Kosten im überschaubarenRahmen zu halten. So solltedie komplette Außenanlage(Weichenantriebe HW60 O-Z,Signale und Sperrkreise) bei -behalten werden. Des Weiterensollten die Stellteile zur Ansteuerungund Überwachung derWeichen und Sperrkreise weitereVerwendung finden.Der ursprüngliche Gedanke, dieBaugruppen zur Ansteuerungund Überwachung der Signaleauch beizubehalten, wurde schonin der frühen Planungsphase gemeinsammit dem Kunden undGutachter wieder gestrichen, sodass an diese Stelle die gewohntzuverlässige Ansteuerung vonHANNING & KAHL diesen Partübernahm. Außerdem wurdensehr viele zusätzliche Fahrwegerealisiert, welche durch den Einsatzhinzugekommener Fahrstraßen-Startsignaleermöglichtwurden.Zeitgleich mit der Betriebshofsteuerung,die über die HN-Pvon HANNING & KAHL und dasBedienen & Beobachten der VerkehrsautomatisierungBerlinGmbH (VAB) realisiert wurde,sollte auch das BetriebshofmanagementsystemBMS der FirmaVAB ersetzt werden. HANNING& KAHL stellte sich in enger Zusammenarbeitmit VAB dieserAufgabe und meisterte sie gewohntprofessionell und zügig.Zu nennen ist an dieser Stelleauch die kooperative Zusammenarbeitmit dem Kunden.Die geplante Realisierung in zweiTeillosen in den Jahren 2009 und2010 wurde weit unterboten unddie Anlage vor den Weihnachtsfeiertagenim Jahre 2009 fertiggestellt.So wurde dem Kundentermingerecht eine moderne undzuverlässige Betriebshofsteuerung2übergeben, die sich über dreiSteuerschränke aufteilt, in welchendie HN-P-Steuerungen zur Ansteuerung,Überwachung undEinlesung der 20 Weichen,20 Signalbegriffe und 30 Sperrkreisesitzen.Des Weiteren wurde in einemRechnerraum der zentraleDatensammler platziert, der dieAnforderung der Fahrstraßenrealisiert sowie die Kommuni -kation zwischen den HN-Ps unddem Bedienen & Beobachten inder Leitstelle gewährleistet. DieserDatensammler dient als Ersatzder Zentralebene der Altanlage,welche über eine S7 CPU315 realisiert wurde. Der schematischeAufbau der Steuerung ist inder nebenstehenden System -architektur ersichtlich und zeigtdie Kommunikationswege dereinzelnen Komponenten.Neben dem erheblich gestiegenenBedienkomfort der BedienoberflächeBedienen & Beobachtenbietet nun auch das BetriebshofmanagementsystemBMS eineungeahnte Fülle an zusätzlichenFunktionen, die von der automatischenFahrstraßenanwahl überdie Visualisierung von Abstellortund Status der Fahrzeuge bis zurEinsatz- und Werkstattplanungreicht.1Blick auf das Verwaltungs -gebäude des Betriebshof PotsdamBabelsbergView of the administration buildingof the Potsdam Babelsbergdepot2Beginn der Arbeiten bei sichtlichkaltem WetterStarting to work in obviously coldweatherHANNING & KAHL hat bewiesen,dass auch Schnittstellen zuanderen Systemen lösbare Aufgabendarstellen und somit auchweitere Kunden über den Teilersatzälterer Anlagenteile nach -denken können. Verfügbarkeitund lebensdauer vorhandenerFahrsignalanlagen oder Betriebshofsteuerungenlassen sich sowirtschaftlich erhöhen.thomas.nagel@hanning-kahl.com10

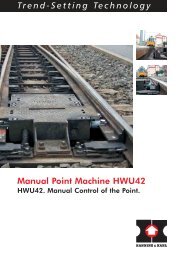

Neue Signalisierung für den Betriebshof PotsdamNew signalling for Potsdam depotThomas Nagel. When assembly work started for the new depotcontroller at Potsdam Babelsberg on 11th December 2009,winter was waiting in the wings with snow and low tempera -tures. No one could forecast that this snow would still be on theground at the end of February. Looking back, it was one of thelongest winters for decades, but inclement weather could notkeep anyone from commissioning the depot controller punctuallyand successfully. As the popular saying goes, there is no suchthing as bad weather - just the wrong clothes.In spring 2009, VerkehrsbetriebePotsdam GmbH (VIP) tenderedfor a new controller for theirdepot at Babelsberg to replacethe ”old“ controller which hadbeen commissioned in 2001.The interlocking control systemand the trackside interlockprocessors were in stored pro -gram control (SPC) version withSimatic S5 AG115U (SPC) asinterlock processor. An SPS S7 –CPU 315 was used on the centrallevel, and VICOS OC-11 stationsfor operation and display.As a result of the outdatedoperating system on the controllevel PCs for operation anddisplay (Windows NT), the datedPC hardware, and discontinuationof different hardware components(e.g.: SIMATIC S5) with difficultspare-part supply, the customerhad to make serious investmentsbefore the end of the desiredservice life of the equipment.Further functions were alsorequested, including enhancedsafety for driving and controlcentre staff, recording of switchingoperations, DCF-time synchroni -sation and more drivingpossibilities.The aim was to keep costsmanageable by only replacingsome of the components. At thebeginning, all outdoor instal -lations (HW60 O-Z pointmachines, signals and blockingcircuits) were to be retained. Theequipment used to control andmonitor points and blockingcircuits was also to remain in use.The original plan to retain thecomponents for signal control andmonitoring was abandoned earlyon by the customer and theassessor in favour of reliableHANNING & KAHL equipment.Many additional secured routeswere made possible with the aidof extra route-start signals.Alongside the depot controller,implemented by HANNING &KAHL’s HN-P and VAB’s Operate& Observe, VAB’s depot mana -gement system (BMS) was alsoreplaced with a more modernversion. HANNING & KAHLmastered these tasks in closecooperation with VAB profes -sionally and efficiently as always.We would also like to thank ourcustomers for their excellentcollaboration.The time frame planned forimplementation in two part lots in2009 and 2010 was substantiallyshortened with installation com -pleted before Christmas 2009.We handed over a state-of-theart,reliable depot controller,distributed among three controlcabinets, containing HN-P vitalinterlocking controllers for control,monitoring and reading-in of20 points, 20 signal aspects and30 blocking circuits.The central data collector waspositioned in a data-processorroom where it processes routerequests and ensures communi -cation between the HN-Ps andthe O&O in the central controlroom. This data collector replacesthe “old“ central level formerlyserved by the S7 – CPU 315. Thediagram above left illustrates thesystem architecture of thecontroller and the communicationpaths of the individual com -ponents.Apart from greater ease ofoperation via the O&O userinterface, the BMS depot mana -gement system also offers a myriadof additional functions, rangingfrom automatic route selection,visualisation of siding location andvehicle status, to resourcescheduling and work shop planning.HANNING & KAHL has proventhat creating interfaces to othersystems is a solvable task. Othercustomers may well think aboutreplacing some elements in orderto increase the availability andservice life of signalling installationsor depot controllers in one step.thomas.nagel@hanning-kahl.com343Darstellung des Betriebshof-Gleisbildes „Bedienen & Beobachten“”Operate and Observe“ depottrack diagram4Stellplatzanzeige des BetriebshofmanagementsystemsBMSParking place display of thedepot management system11