Tank + Chemie- - bei ELAFLEX

Tank + Chemie- - bei ELAFLEX

Tank + Chemie- - bei ELAFLEX

- Keine Tags gefunden...

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

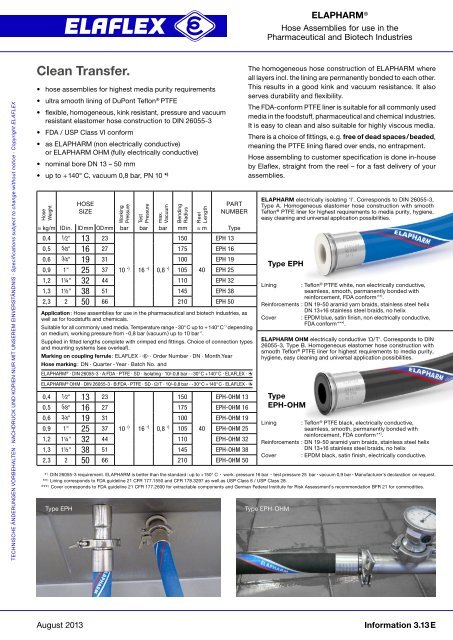

ELAPHARM ®Hose Assemblies for use in thePharmaceutical and Biotech IndustriesTECHNISCHE ÄNDERUNGEN VORBEHALTEN · NACHDRUCK UND KOPIEN NUR MIT UNSEREM EINVERSTÄNDNIS · Specifications subject to change without notice · Copyright <strong>ELAFLEX</strong>Clean Transfer.• hose assemblies for highest media purity requirements• ultra smooth lining of DuPont Teflon ® PTFE• flexible, homogeneous, kink resistant, pressure and vacuumresistant elastomer hose construction to DIN 26055-3• FDA / USP Class VI conform• as ELAPHARM (non electrically conductive)or ELAPHARM OHM (fully electrically conductive)• nominal bore DN 13 – 50 mm• up to + 140° C, vacuum 0,8 bar, PN 10 * )HoseWeightType EPHHOSESIZEWorkingPressureTestPressuremax.VacuumBendingRadiusReelLengthPARTNUMBER≈ kg/m ID in. ID mm OD mm bar bar bar mm ≈ m Type0,4 1⁄2" 13 23150 EPH 130,9 1" 25 37 10 *) 16 *) 0,8 *) 105 40 EPH 250,5 5⁄8" 16 27 175 EPH 160,6 3⁄4" 19 31 100 EPH 191,2 1¼ " 32 44 110 EPH 321,3 1½ " 38 51 145 EPH 382,3 2 50 66 210 EPH 50Application: Hose assemblies for use in the pharmaceutical and biotech industries, aswell as for foodstuffs and chemicals.Suitable for all commonly used media. Temperature range - 30° C up to + 140° C *) dependingon medium, working pressure from - 0,8 bar (vacuum) up to 10 bar *) .Supplied in fitted lengths complete with crimped end fittings. Choice of connection typesand mounting systems (see overleaf).Marking on coupling ferrule: <strong>ELAFLEX</strong> · · Order Number · DN · Month.YearHose marking: DN · Quarter - Year · Batch No. andELAPHARM ® · DIN 26055-3 · A:FDA · PTFE · SD · Isolating · 10/-0,8 bar · - 30° C + 140° C · <strong>ELAFLEX</strong> ·ELAPHARM ® OHM · DIN 26055-3 · B:FDA · PTFE · SD · Ω/T · 10/-0,8 bar · - 30° C + 140° C · <strong>ELAFLEX</strong> ·0,4 1⁄2" 13 23150 EPH-OHM 130,9 1" 25 37 10 *) 16 *) 0,8 *) 105 40 EPH-OHM 250,5 5⁄8" 16 27 175 EPH-OHM 160,6 3⁄4" 19 31 100 EPH-OHM 191,2 1¼ " 32 44 110 EPH-OHM 321,3 1½ " 38 51 145 EPH-OHM 382,3 2 50 66 210 EPH-OHM 50The homogeneous hose construction of ELAPHARM whereall layers incl. the lining are permanently bonded to each other.This results in a good kink and vacuum resistance. It alsoserves durability and flexibility.The FDA-conform PTFE liner is suitable for all commonly usedmedia in the foodstuff, pharmaceutical and chemical industries.It is easy to clean and also suitable for highly viscous media.There is a choice of fittings, e. g. free of dead spaces / beaded,meaning the PTFE lining flared over ends, no entrapment.Hose assembling to customer specification is done in-houseby Elaflex, straight from the reel – for a fast delivery of yourassemblies.ELAPHARM electrically isolating ' I '. Corresponds to DIN 26055-3,Type A. Homogeneous elastomer hose construction with smoothTeflon ® PTFE liner for highest requirements to media purity, hygiene,easy cleaning and universal application possibilities.Type EPHLining : Teflon ® PTFE white, non electrically conductive,seamless, smooth, permanently bonded withreinforcement, FDA conform ** ) .Reinforcements : DN 19-50 aramid yarn braids, stainless steel helixDN 13+16 stainless steel braids, no helixCover : EPDM blue, satin finish, non electrically conductive,FDA conform *** ) .ELAPHARM OHM electrically conductive 'Ω / T'. Corresponds to DIN26055-3, Type B. Homogeneous elastomer hose construction withsmooth Teflon ® PTFE liner for highest requirements to media purity,hygiene, easy cleaning and universal application possibilities.TypeEPH-OHMLining : Teflon ® PTFE black, electrically conductive,seamless, smooth, permanently bonded withreinforcement, FDA conform ** ) .Reinforcements : DN 19-50 aramid yarn braids, stainless steel helixDN 13+16 stainless steel braids, no helixCover : EPDM black, satin finish, electrically conductive.* ) DIN 26055-3 requirement. ELAPHARM is better than the standard : up to + 150° C • work. pressure 16 bar • test pressure 25 bar • vacuum 0,9 bar • Manufacturer's declaration on request.** ) Lining corresponds to FDA guideline 21 CFR 177.1550 and CFR 178.3297 as well as USP Class 6 / USP Class 28.*** ) Cover corresponds to FDA guideline 21 CFR 177.2600 for extractable components and German Federal Institute for Risk Assessment's recommendation BFR 21 for commodities.Type EPH-OHMAugust 2013Information 3.13 E