Installation Manual - CertainTeed

Installation Manual - CertainTeed

Installation Manual - CertainTeed

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>CertainTeed</strong> WeatherBoards Fiber Cement Siding <strong>Installation</strong> <strong>Manual</strong><br />

Butt and End Joint Application<br />

There are three ways to fasten butt and end joints:<br />

1. Into solid framing<br />

2. Into structural sheathing<br />

3. With an off-stud joiner<br />

Butt End/Joints Fastened into Solid Framing<br />

or Structural Sheathing<br />

Butt end/joints should be installed with factory-sealed<br />

or factory-prefinished ends butted together in moderate<br />

contact. We recommend that butt end/joints be fastened<br />

into a stud or framing member. If no stud or framing<br />

member is available, butt end/joints may be fastened into<br />

structural-rated sheathing.<br />

When installing WeatherBoards lap siding, you must<br />

install butt joints using either backflashing, joint covers,<br />

or H-covers. Consult local code for butt joint treatment<br />

requirements in your area. Backflashing should be<br />

constructed of a durable, non-corrosive material that is<br />

compatible with fiber cement. Do not attempt to flash<br />

behind end or butt joints with housewrap—housewrap<br />

will not direct water away from the wall. Flashing size<br />

should be a minimum of 6" wide (3" to the left and right<br />

of the joint) and extend at least 1" over the top of the<br />

previous course. Examples of butt end/joint flashing<br />

materials include:<br />

X X#15<br />

felt<br />

XXTrim coil (painted or PVC coated)<br />

XXBear Skin Joint Flashing<br />

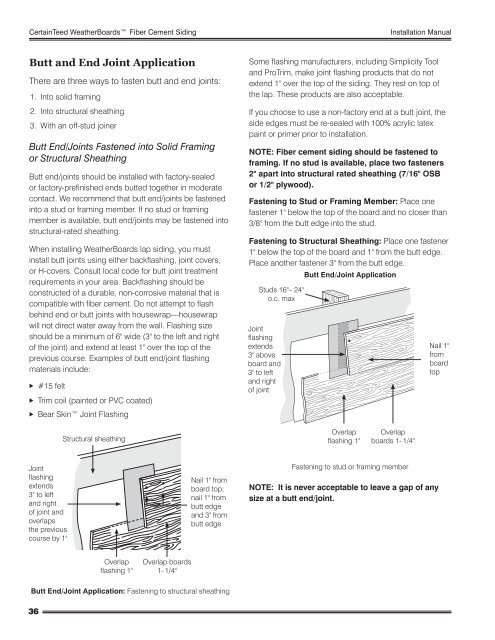

Joint<br />

flashing<br />

extends<br />

3" to left<br />

and right<br />

of joint and<br />

overlaps<br />

the previous<br />

course by 1"<br />

Butt End/Joint Application: Fastening to structural sheathing<br />

36<br />

Structural sheathing<br />

Overlap<br />

flashing 1"<br />

Overlap boards<br />

1- 1/4"<br />

Nail 1" from<br />

board top;<br />

nail 1" from<br />

butt edge<br />

and 3" from<br />

butt edge<br />

Some flashing manufacturers, including Simplicity Tool<br />

and ProTrim, make joint flashing products that do not<br />

extend 1" over the top of the siding. They rest on top of<br />

the lap. These products are also acceptable.<br />

If you choose to use a non-factory end at a butt joint, the<br />

side edges must be re-sealed with 100% acrylic latex<br />

paint or primer prior to installation.<br />

NOTE: Fiber cement siding should be fastened to<br />

framing. If no stud is available, place two fasteners<br />

2" apart into structural rated sheathing (7/16" OSB<br />

or 1/2" plywood).<br />

Fastening to Stud or Framing Member: Place one<br />

fastener 1" below the top of the board and no closer than<br />

3/8" from the butt edge into the stud.<br />

Fastening to Structural Sheathing: Place one fastener<br />

1" below the top of the board and 1" from the butt edge.<br />

Place another fastener 3" from the butt edge.<br />

Butt End/Joint Application<br />

Studs 16"– 24"<br />

o.c. max<br />

Joint<br />

flashing<br />

extends<br />

3" above<br />

board and<br />

3" to left<br />

and right<br />

of joint<br />

Overlap<br />

flashing 1"<br />

Overlap<br />

boards 1- 1/4"<br />

Fastening to stud or framing member<br />

NOTE: It is never acceptable to leave a gap of any<br />

size at a butt end/joint.<br />

Nail 1"<br />

from<br />

board<br />

top