Trre OnIGINAL HONAE WOOOWORKING RruN ... - Wood Tools

Trre OnIGINAL HONAE WOOOWORKING RruN ... - Wood Tools

Trre OnIGINAL HONAE WOOOWORKING RruN ... - Wood Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SETECT SilRAIGITT STOGK<br />

A straight fence starts with straight<br />

lumber, but it was tough finding<br />

1x4's at my local lumber yard that<br />

werent crooked or full of knots.<br />

Since I needed some 1x12 stock as<br />

well, I decided to look for it instead,<br />

and found a rack with some beautifirl<br />

16-footers. Quickly calculating<br />

lumber yield in the wider boards, I<br />

bought most of the pile. Even<br />

though it meant ripping a few<br />

boards to get the narrower widths I<br />

needed (not a pleasant task given<br />

cedar's irritating sawdust), the<br />

resulting straight-grained stock was<br />

worth the extra trouble.<br />

START WMI THE SGREEN<br />

One ofthe beauties ofthis fence is its<br />

repetition of elements. The "screen"<br />

- named for its role in screening the<br />

yard from view - consisB of an<br />

alternating pattern of narrow and<br />

wide infill boards separated by 1"wide<br />

gaps (FENCE coNsrRuc-<br />

TION vIEw). As I ripped the infill<br />

Cut $e lover and upper raib to httgUt,<br />

align tie endq then uss a tape and a<br />

squarc b mad($e Inf,ll boad locatiotts<br />

- mrt boft ed$s of each affill boad.<br />

boards to width, I noticed that the<br />

color varied gready fiom one board<br />

to the next. I kept this in mind so<br />

that later, when I assembled the<br />

screens, I could mix the boards to<br />

make sure each section contained a<br />

similar blend of light and dark.<br />

With the parts cut and sorted, I<br />

placed one upper and one lower rail<br />

Alignfteffi boadsand moud<br />

dnm withtvooftetsqerus in<br />

eadt. l.eave Ute top etds Ys" protd<br />

of the upper nll.<br />

together and carefirlly marked the<br />

location of the infill boards (rtc. 1).<br />

Next, I began attaching the infill<br />

boards to the lower rail (rtC. 2). Use<br />

screws here for strength - the heads<br />

will be hidden by the opposing rail.<br />

Allow the infill boards to extend 1/8"<br />

past the top edge of the upper rail as<br />

you screw the infill boards in place.<br />

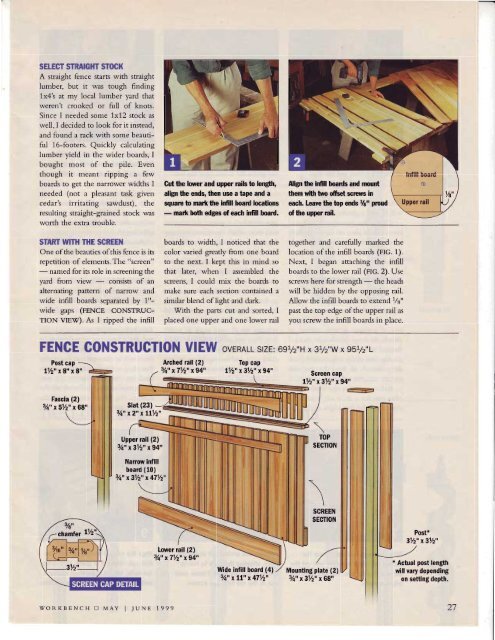

FENGE CONSTRUCTION VIEW ovERALL stzE:6e!/z"H x312"w xes!/z"L<br />

Post cap<br />

Arched rall (2)<br />

1%"x8nx8n Vc"x71hx94"<br />

Scrcen cap<br />

lVz" x3Vz" x94"<br />

-<br />

'<br />

Ve"<br />

chamfer 1<br />

Upper nll (2)<br />

Vq" x31/2" x94<br />

llanow Inflll<br />

boad (10)<br />

E/4" x3Y2" r47Y2"<br />

lower nll (2)<br />

V+" xf/2" x94"<br />

Wlde Inflll boad (4)<br />

V{ xll" x471/2"<br />

\<br />

TOP<br />

sEcIt0l{<br />

\<br />

SCREEII<br />

sEcfl0il<br />

Mounung platc (2)<br />

3y4u atl2r x68"<br />

Post*<br />

!!2" x!1/2"<br />

* Actual post length<br />

wlll vary dependlng<br />

on settlng depth.<br />

WoRKBENCH O MAY I JUNE 1999 27

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)