Trre OnIGINAL HONAE WOOOWORKING RruN ... - Wood Tools

Trre OnIGINAL HONAE WOOOWORKING RruN ... - Wood Tools

Trre OnIGINAL HONAE WOOOWORKING RruN ... - Wood Tools

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

abiliry to hold a cutting edge. That's<br />

the first thing to remember about<br />

drills - that the rotational speed<br />

(rpm), feed rate, bit rype, hole diameter,<br />

and workpiece properties must<br />

be balanced to avoid heat build-up<br />

or tool failure. For deep holes especially,<br />

backing the bit out periodically<br />

to clear chips will help dissipate<br />

the heat before it's a problem.<br />

Keep in mind also that the forces<br />

involved change rapidly for larger<br />

holes. It's the area of the circle, not<br />

the diameter, that represents the<br />

material you're removing. For<br />

example, a 1"-dia. hole is four times<br />

larger than a 1/2" hole, though its<br />

diameter is only hvice as great. For<br />

safery's sake, large-diameter bits have<br />

to rotate at significantly slower<br />

speeds than smaller drills do.<br />

TWIST DRILLS: IllE BASIC M0DEL<br />

Twist drills are easily the most common<br />

rype around today, in part<br />

because they are so versatile. Most<br />

are made from high-speed steel,<br />

which can withstand high temperatures<br />

without "burning." They can<br />

be used to drill almost any metal,<br />

plastic. wood, or composite material.<br />

but in larger sizes (over l/2") Because rwist drills are designed<br />

for use with metal, they feature a<br />

slighdy blunted nose that won't<br />

deform under pressure against a<br />

hard suface. The tradeoff for this<br />

feature is a tendency to spin away<br />

from the intended hole center, a<br />

habit known as walking or skating.<br />

Recently, manufacturers have<br />

been grinding new tip profiles on<br />

rwist drills to make them stay put<br />

when starting a hole. Called "pilotpoints"<br />

or "bullet-points," these do<br />

improve a bit's precision, but their<br />

complex geometry usually means<br />

do-it-yourself sharpening isn't an<br />

option.'Whatever their shortcomings,<br />

standard rwist drills can at least<br />

be sharpened easily on a bench<br />

grinder or with an inexpensive drill<br />

sharpening accessory.<br />

Titanium-nitride (TiN) coatings<br />

on some bits add hardness and a<br />

self-lubricating properry but this<br />

gold-colored microthin coating<br />

improves metal-drilling only, with<br />

little or no difference in wood.<br />

W0OD-BORlltlG BfiS<br />

'<strong>Wood</strong><br />

is softer and machines differently<br />

than metal, and specialized bits<br />

they have evolved for drilling it.<br />

can get pretty expensive, especially For instance, drill bits designed<br />

relative to other rypes ofbits.<br />

for wood have a center point that<br />

TWIST DRILT BIili<br />

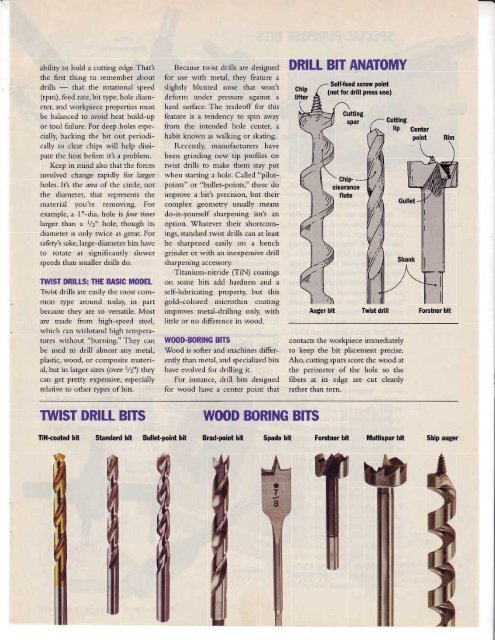

DRITL BIT ANATOMY<br />

Chip<br />

llfter<br />

Auger blt<br />

WOOD BORING BITS<br />

liil-coated bit Standard bit Bullet-point bit Brad-poirt bit Spade bit<br />

Self-feed screw polnt<br />

(not for drlll press use)<br />

Cutting<br />

spur<br />

Chlp<br />

clearance<br />

flute<br />

Twlst drlll<br />

contacts the workpiece immediately<br />

to keep the bit placement precise.<br />

Also, cutting spurs score the wood at<br />

the perimeter of the hole so the<br />

fibers at its edge are cut cleanly<br />

rather than torn.<br />

Forstner blt<br />

Forstner bit Muftispur bit Ship auger

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)