Trre OnIGINAL HONAE WOOOWORKING RruN ... - Wood Tools

Trre OnIGINAL HONAE WOOOWORKING RruN ... - Wood Tools

Trre OnIGINAL HONAE WOOOWORKING RruN ... - Wood Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

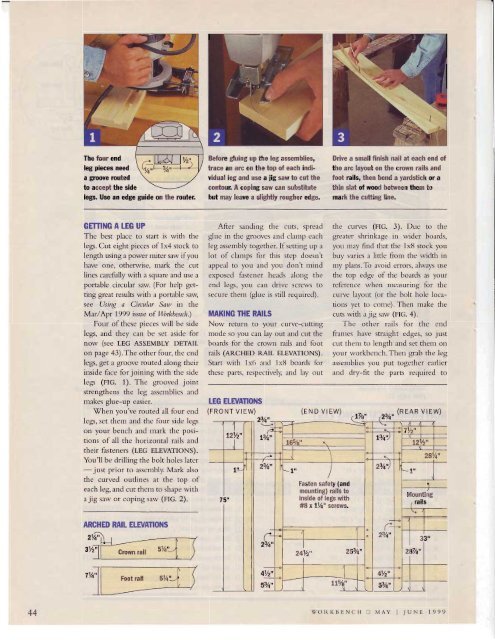

The four end<br />

leg pieces need<br />

a grcove routed<br />

to accept the side<br />

legs. Use an edge guide on the routen<br />

GE]TING A LEG<br />

UP<br />

The best place to start is with the<br />

legs. Cut eight pieces of 1x4 stock to<br />

length using a power miter saw ifyou<br />

have one. otherwise. mark the cut<br />

lines carefully with a square and use a<br />

portable circular saw. (For help get-<br />

ting great results with a portable saw,<br />

see Using a Circular Sar.y in the<br />

Mar/Apr 1999 issue of Workbench.)<br />

Four of these pieces will be side<br />

legs, and they can be set aside for<br />

now (see LEG ASSEMBLY DETAIL<br />

on page 43).The other four, the end<br />

legs, get a groove routed along their<br />

inside face for joining with the side<br />

Iegs (rtc. 1). The grooved joint<br />

strengthens the leg assemblies and<br />

makes glue-up easier.<br />

When you've routed all four end<br />

legs, set them and the four side legs<br />

on your bench and mark the posi-<br />

tions of all the horizontal rails and<br />

their fasreners (rEc ELEVATTONS).<br />

You'Il be drilling the bolt holes later<br />

- just prior to assembly. Mark also<br />

the curved outlines at the top of<br />

each leg, and cut them to shape with<br />

ajig saw or coping saw (rtc. 2).<br />

ARCHED RAIL ELEIIATIONS<br />

,'2"\_r<br />

tr1;<br />

Before gluing up the leg assemblies,<br />

trace an arc on the top of each individual<br />

leg and use a jig saw to cut the<br />

contour. A coping saw can substitute<br />

but may leave a slightly rougher edge.<br />

After sanding the cuts, spread<br />

glue in the grooves and clamp each<br />

leg assembly together. If serting up a<br />

lot of clamps for this step doesn't<br />

appeal to you and you don't mind<br />

exposed fastener heads along the<br />

end legs, you can drive screws to<br />

secure then (glue is still required).<br />

MAIflNG THE RAITS<br />

Now return to your curve-cutting<br />

nrode so you can lay out and cut the<br />

boards for the crown rails and foot<br />

rails (an.CHED RArL ELEVATToNS).<br />

Start with 1x6 and 1x8 boards for<br />

these parts, respectively, and lay out<br />

HG EInIANONS<br />

(FRONT<br />

VIEW)<br />

Ilrive a small finish nail at each end of<br />

the arc layout on the crown rails and<br />

foot rails, then bend a yardstick or a<br />

thin slat of wood between them to<br />

mark the cutting line.<br />

the curves (FIG. 3). Due to the<br />

greater shrinkage in wider boards,<br />

you nlay find that the 1x8 stock you<br />

buy varies a little from the width in<br />

my plans. To avoid errors, always use<br />

the top edge of the boards as your<br />

reference when nreasuring for the<br />

curve layout (or the bolt hole loca-<br />

tions yet to come). Then nake the<br />

cuts with a jig saw (Etc.4).<br />

The other rails for the end<br />

frames have straight edges, so just<br />

cut thenl to length and set them on<br />

your workbench.Then grab the leg<br />

assemblies you put together earlier<br />

and dry-fit the parts required to<br />

(END VIEW) (REAR VrEW)<br />

Fasten safeg (and<br />

mounting) rails to<br />

inside of legs wath<br />

#8 x 17a" sqews.<br />

Mounting<br />

44 woRKBENcH tr MAy I JUNE 1999

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)