Trre OnIGINAL HONAE WOOOWORKING RruN ... - Wood Tools

Trre OnIGINAL HONAE WOOOWORKING RruN ... - Wood Tools

Trre OnIGINAL HONAE WOOOWORKING RruN ... - Wood Tools

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

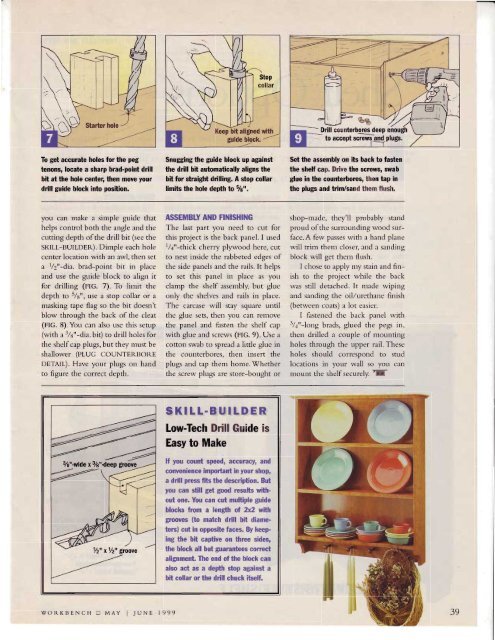

Iio get accurate holes for the peg<br />

tenons, locate a sharp brad-point ddll<br />

bit at the hole certer, then move your<br />

drill guide block irto position.<br />

you can make a simple guide that<br />

helps control both the angle and the<br />

cutting depth of the drill bit (see the<br />

SKILL-BUILDER). Dimple each hole<br />

center location with an awl, then set<br />

a 1/2"-dit. brad-point bit in place<br />

and use the guide block to align it<br />

for drilling (rIc. 7). To limit the<br />

depth to 5/8", use a stop collar or a<br />

masking tape flag so the bit doesn't<br />

blow through the back of the cleat<br />

(nc. 8).You can also use this setup<br />

(with a 3/e"-dia.bit) to drill holes for<br />

the shelf cap plugs, but they must be<br />

shallower (PLUG CoUNTERBoRE<br />

DETAIL). Have your plugs on hand<br />

to figure the correct depth.<br />

3/8"{lde x 3/a"{eep gruove<br />

Keep blt allgned wlth<br />

SnugEing the guide block up against<br />

the drill bit automatically aligns the<br />

bit for stralgiltt drilling. A stop collar<br />

limits the hole depth to 5/e".<br />

ASSEMBLY AND FINISHING<br />

The last part you need to cut for<br />

this project is the back panel. I used<br />

1/+"-thick cherry plywood here, cut<br />

to nest inside the rabbeted edges of<br />

the side panels and the rails. It helps<br />

to set this panel in place as you<br />

clamp the shelf assembly, but glue<br />

only the shelves and rails in place.<br />

The carcase will stay square until<br />

the glue sets, then you can remove<br />

the panel and fasten the shelf cap<br />

with glue and screws (rIc. 9). Use a<br />

cotton swab to spread a little glue in<br />

the counterbores, then insert the<br />

plugs and tap them home.Whether<br />

the screw plugs are store-bought or<br />

SKItt.BUILDER<br />

Low-Tech Drill Guide is<br />

Easy to Make<br />

lf you count speed, accuracy, and<br />

convenience important in your shop,<br />

a drill prcss fits the descrip,tion. But<br />

you can still get good results without<br />

one. You can cut multiple guide<br />

blocks from a length st M, wilh<br />

gnxrves lto match drill bit diameterc)<br />

cut in opposite faces. By keep<br />

ing the bit captive on three sides,<br />

the block all but guarartees correc't<br />

alignmert. The end of the block can<br />

also act as a depth stop against a<br />

bit collar or the drill chuck itself.<br />

Set the assembly on its back to fasten<br />

the shelf cap. Drive the scrcws, swab<br />

glue in the courterborcs, then tap in<br />

the plugs and trim/sand them flush.<br />

shop-made, they'll probably stand<br />

proud of the surrounding wood sur-<br />

face. A few passes with a hand plane<br />

will trim them closer, and a sanding<br />

block will get them flush.<br />

I chose to apply my stain and fin-<br />

ish to the project while the back<br />

was still detached. It made wiping<br />

and sanding the oillurethane finish<br />

(between coats) a lot easter.<br />

I fastened the back panel with<br />

3/4"-long brads, glued the pegs in,<br />

then drilled a couple of mounting<br />

holes through the upper rail. These<br />

holes should correspond to stud<br />

locations in your wall so you can<br />

mount the shelf securely. t[<br />

WORKBENCH ! MAY I IUNE 1999 39

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)