JP 4-01.5 JTTP for Water Terminal Operations - BITS

JP 4-01.5 JTTP for Water Terminal Operations - BITS

JP 4-01.5 JTTP for Water Terminal Operations - BITS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter I<br />

properly cleared <strong>for</strong> handling classified cargo.<br />

Additionally, bulk fuel ships will normally<br />

dock at special fuel unloading facilities;<br />

however, they may also be discharged at<br />

offshore anchorages using specialized<br />

equipment.<br />

c. Methods <strong>for</strong> Cargo Handling. <strong>Water</strong><br />

terminals are categorized by the type of cargohandling<br />

capability being employed. These<br />

handling capabilities are listed below.<br />

I-4<br />

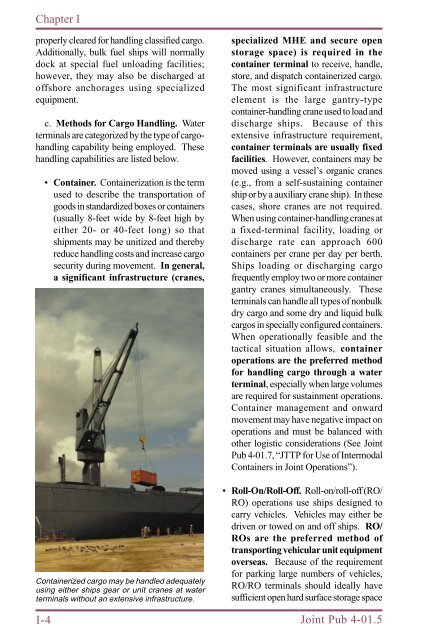

• Container. Containerization is the term<br />

used to describe the transportation of<br />

goods in standardized boxes or containers<br />

(usually 8-feet wide by 8-feet high by<br />

either 20- or 40-feet long) so that<br />

shipments may be unitized and thereby<br />

reduce handling costs and increase cargo<br />

security during movement. In general,<br />

a significant infrastructure (cranes,<br />

Containerized cargo may be handled adequately<br />

using either ships gear or unit cranes at water<br />

terminals without an extensive infrastructure.<br />

specialized MHE and secure open<br />

storage space) is required in the<br />

container terminal to receive, handle,<br />

store, and dispatch containerized cargo.<br />

The most significant infrastructure<br />

element is the large gantry-type<br />

container-handling crane used to load and<br />

discharge ships. Because of this<br />

extensive infrastructure requirement,<br />

container terminals are usually fixed<br />

facilities. However, containers may be<br />

moved using a vessel’s organic cranes<br />

(e.g., from a self-sustaining container<br />

ship or by a auxiliary crane ship). In these<br />

cases, shore cranes are not required.<br />

When using container-handling cranes at<br />

a fixed-terminal facility, loading or<br />

discharge rate can approach 600<br />

containers per crane per day per berth.<br />

Ships loading or discharging cargo<br />

frequently employ two or more container<br />

gantry cranes simultaneously. These<br />

terminals can handle all types of nonbulk<br />

dry cargo and some dry and liquid bulk<br />

cargos in specially configured containers.<br />

When operationally feasible and the<br />

tactical situation allows, container<br />

operations are the preferred method<br />

<strong>for</strong> handling cargo through a water<br />

terminal, especially when large volumes<br />

are required <strong>for</strong> sustainment operations.<br />

Container management and onward<br />

movement may have negative impact on<br />

operations and must be balanced with<br />

other logistic considerations (See Joint<br />

Pub 4-01.7, “<strong>JTTP</strong> <strong>for</strong> Use of Intermodal<br />

Containers in Joint <strong>Operations</strong>”).<br />

• Roll-On/Roll-Off. Roll-on/roll-off (RO/<br />

RO) operations use ships designed to<br />

carry vehicles. Vehicles may either be<br />

driven or towed on and off ships. RO/<br />

ROs are the preferred method of<br />

transporting vehicular unit equipment<br />

overseas. Because of the requirement<br />

<strong>for</strong> parking large numbers of vehicles,<br />

RO/RO terminals should ideally have<br />

sufficient open hard surface storage space<br />

Joint Pub 4-<strong>01.5</strong>