JP 4-01.5 JTTP for Water Terminal Operations - BITS

JP 4-01.5 JTTP for Water Terminal Operations - BITS

JP 4-01.5 JTTP for Water Terminal Operations - BITS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter III<br />

hold and process cargo pending further<br />

movement.<br />

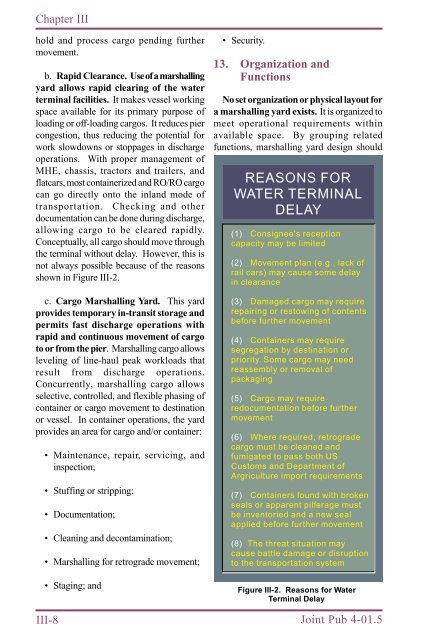

b. Rapid Clearance. Use of a marshalling<br />

yard allows rapid clearing of the water<br />

terminal facilities. It makes vessel working<br />

space available <strong>for</strong> its primary purpose of<br />

loading or off-loading cargos. It reduces pier<br />

congestion, thus reducing the potential <strong>for</strong><br />

work slowdowns or stoppages in discharge<br />

operations. With proper management of<br />

MHE, chassis, tractors and trailers, and<br />

flatcars, most containerized and RO/RO cargo<br />

can go directly onto the inland mode of<br />

transportation. Checking and other<br />

documentation can be done during discharge,<br />

allowing cargo to be cleared rapidly.<br />

Conceptually, all cargo should move through<br />

the terminal without delay. However, this is<br />

not always possible because of the reasons<br />

shown in Figure III-2.<br />

c. Cargo Marshalling Yard. This yard<br />

provides temporary in-transit storage and<br />

permits fast discharge operations with<br />

rapid and continuous movement of cargo<br />

to or from the pier. Marshalling cargo allows<br />

leveling of line-haul peak workloads that<br />

result from discharge operations.<br />

Concurrently, marshalling cargo allows<br />

selective, controlled, and flexible phasing of<br />

container or cargo movement to destination<br />

or vessel. In container operations, the yard<br />

provides an area <strong>for</strong> cargo and/or container:<br />

• Maintenance, repair, servicing, and<br />

inspection;<br />

• Stuffing or stripping;<br />

• Documentation;<br />

• Cleaning and decontamination;<br />

• Marshalling <strong>for</strong> retrograde movement;<br />

III-8<br />

• Security.<br />

13. Organization and<br />

Functions<br />

No set organization or physical layout <strong>for</strong><br />

a marshalling yard exists. It is organized to<br />

meet operational requirements within<br />

available space. By grouping related<br />

functions, marshalling yard design should<br />

REASONS FOR<br />

WATER TERMINAL<br />

DELAY<br />

(1) Consignee's reception<br />

capacity may be limited<br />

(2) Movement plan (e.g., lack of<br />

rail cars) may cause some delay<br />

in clearance<br />

(3) Damaged cargo may require<br />

repairing or restowing of contents<br />

be<strong>for</strong>e further movement<br />

(4) Containers may require<br />

segregation by destination or<br />

priority. Some cargo may need<br />

reassembly or removal of<br />

packaging<br />

(5) Cargo may require<br />

redocumentation be<strong>for</strong>e further<br />

movement<br />

(6) Where required, retrograde<br />

cargo must be cleaned and<br />

fumigated to pass both US<br />

Customs and Department of<br />

Argriculture import requirements<br />

(7) Containers found with broken<br />

seals or apparent pilferage must<br />

be inventoried and a new seal<br />

applied be<strong>for</strong>e further movement<br />

(8) The threat situation may<br />

cause battle damage or disruption<br />

to the transportation system<br />

• Staging; and Figure III-2. Reasons <strong>for</strong> <strong>Water</strong><br />

<strong>Terminal</strong> Delay<br />

Joint Pub 4-<strong>01.5</strong>