2000 by the National Roofing Contractors Association. No

2000 by the National Roofing Contractors Association. No

2000 by the National Roofing Contractors Association. No

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

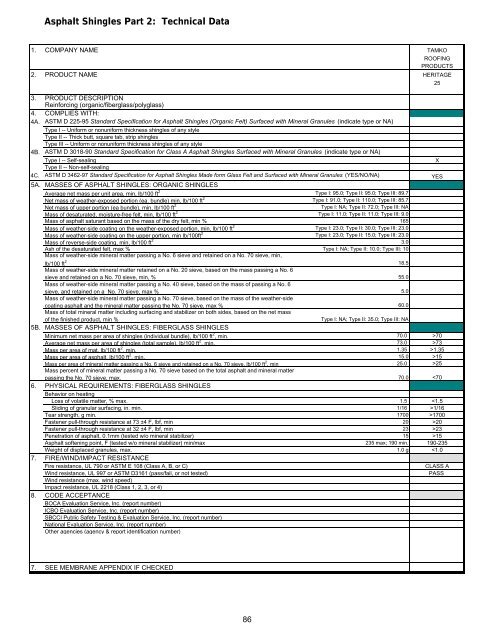

Asphalt Shingles Part 2: Technical Data<br />

1. COMPANY NAME TAMKO<br />

ROOFING<br />

PRODUCTS<br />

2. PRODUCT NAME HERITAGE<br />

25<br />

3. PRODUCT DESCRIPTION<br />

Reinforcing (organic/fiberglass/polyglass)<br />

4. COMPLIES WITH:<br />

4A.<br />

Type I -- Uniform or nonuniform thickness shingles of any style<br />

Type II -- Thick butt, square tab, strip shingles<br />

Type III -- Uniform or nonuniform thickness shingles of any style<br />

4B.<br />

Type I -- Self-sealing<br />

Type II -- <strong>No</strong>n-self-sealing<br />

X<br />

4C. YES<br />

5A. MASSES OF ASPHALT SHINGLES: ORGANIC SHINGLES<br />

Average net mass per unit area, min, lb/100 ft 2 Type I: 95.0; Type II: 95.0; Type III: 89.7<br />

Net mass of wea<strong>the</strong>r-exposed portion (ea. bundle) min, lb/100 ft 2 Type I: 91.0; Type II: 110.0; Type III: 85.7<br />

Net mass of upper portion (ea bundle), min, lb/100 ft 2 Type I: NA; Type II: 72.0; Type III: NA<br />

Mass of desaturated, moisture-free felt, min, lb/100 ft 2 Type I: 11.0; Type II: 11.0; Type III: 9.0<br />

Mass of asphalt saturant based on <strong>the</strong> mass of <strong>the</strong> dry felt, min % 165<br />

Mass of wea<strong>the</strong>r-side coating on <strong>the</strong> wea<strong>the</strong>r-exposed portion, min, lb/100 ft 2 Type I: 23.0; Type II: 30.0; Type III: 23.0<br />

Mass of wea<strong>the</strong>r-side coating on <strong>the</strong> upper portion, min lb/100ft 2 Type I: 23.0; Type II: 15.0; Type III: 23.0<br />

Mass of reverse-side coating, min, lb/100 ft 2 3.0<br />

Ash of <strong>the</strong> desaturated felt, max %<br />

Mass of wea<strong>the</strong>r-side mineral matter passing a <strong>No</strong>. 6 sieve and retained on a <strong>No</strong>. 70 sieve, min,<br />

Type I: NA; Type II: 10.0; Type III: 10<br />

lb/100 ft 2 Mass of wea<strong>the</strong>r-side mineral matter retained on a <strong>No</strong>. 20 sieve, based on <strong>the</strong> mass passing a <strong>No</strong>. 6<br />

18.5<br />

sieve and retained on a <strong>No</strong>. 70 sieve, min, %<br />

Mass of wea<strong>the</strong>r-side mineral matter passing a <strong>No</strong>. 40 sieve, based on <strong>the</strong> mass of passing a <strong>No</strong>. 6<br />

55.0<br />

sieve, and retained on a <strong>No</strong>. 70 sieve, max %<br />

Mass of wea<strong>the</strong>r-side mineral matter passing a <strong>No</strong>. 70 sieve, based on <strong>the</strong> mass of <strong>the</strong> wea<strong>the</strong>r-side<br />

5.0<br />

coating asphalt and <strong>the</strong> mineral matter passing <strong>the</strong> <strong>No</strong>. 70 sieve, max %<br />

Mass of total mineral matter including surfacing and stabilizer on both sides, based on <strong>the</strong> net mass<br />

60.0<br />

of <strong>the</strong> finished product, min %<br />

5B. MASSES OF ASPHALT SHINGLES: FIBERGLASS SHINGLES<br />

Type I: NA; Type II: 35.0; Type III: NA<br />

Minimum net mass per area of shingles (individual bundle), lb/100 ft 2 , min. 70.0 >70<br />

Average net mass per area of shingles (total sample), lb/100 ft 2 , min. 73.0 >73<br />

Mass per area of mat, lb/100 ft 2 , min. 1.35 >1.35<br />

Mass per area of asphalt, lb/100 ft 2 , min. 15.0 >15<br />

Mass per area of mineral matter passing a <strong>No</strong>. 6 sieve and retained on a <strong>No</strong>. 70 sieve, lb/100 ft 2 ASTM D 225-95 Standard Specification for Asphalt Shingles (Organic Felt) Surfaced with Mineral Granules (indicate type or NA)<br />

ASTM D 3018-90 Standard Specification for Class A Asphalt Shingles Surfaced with Mineral Granules (indicate type or NA)<br />

ASTM D 3462-97 Standard Specification for Asphalt Shingles Made form Glass Felt and Surfaced with Mineral Granules (YES/NO/NA)<br />

, min<br />

Mass percent of mineral matter passing a <strong>No</strong>. 70 sieve based on <strong>the</strong> total asphalt and mineral matter<br />

25.0 >25<br />

passing <strong>the</strong> <strong>No</strong>. 70 sieve, max. 70.0 1700<br />

Fastener pull-through resistance at 73 ±4 F, lbf, min 20 >20<br />

Fastener pull-through resistance at 32 ±4 F, lbf, min 23 >23<br />

Penetration of asphalt, 0.1mm (tested w/o mineral stabilizer) 15 >15<br />

Asphalt softening point, F (tested w/o mineral stabilizer) min/max 235 max; 190 min. 190-235<br />

Weight of displaced granules, max. 1.0 g