January 2006 (PDF 2.9 MB) - Barrick Gold Corporation

January 2006 (PDF 2.9 MB) - Barrick Gold Corporation

January 2006 (PDF 2.9 MB) - Barrick Gold Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

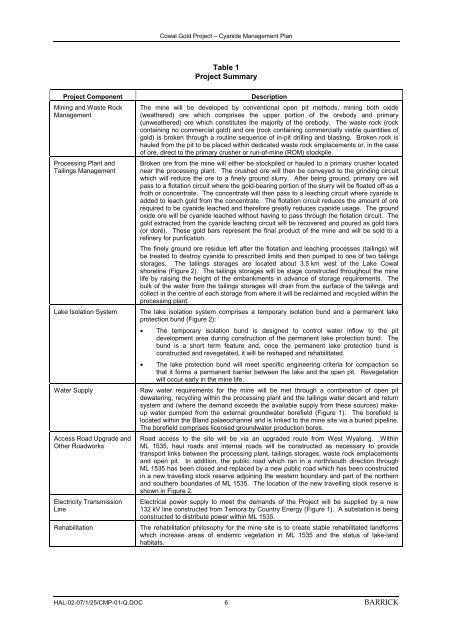

Cowal <strong>Gold</strong> Project – Cyanide Management Plan<br />

Table 1<br />

Project Summary<br />

Project Component Description<br />

Mining and Waste Rock<br />

Management<br />

Processing Plant and<br />

Tailings Management<br />

Lake Isolation System<br />

The mine will be developed by conventional open pit methods, mining both oxide<br />

(weathered) ore which comprises the upper portion of the orebody and primary<br />

(unweathered) ore which constitutes the majority of the orebody. The waste rock (rock<br />

containing no commercial gold) and ore (rock containing commercially viable quantities of<br />

gold) is broken through a routine sequence of in-pit drilling and blasting. Broken rock is<br />

hauled from the pit to be placed within dedicated waste rock emplacements or, in the case<br />

of ore, direct to the primary crusher or run-of-mine (ROM) stockpile.<br />

Broken ore from the mine will either be stockpiled or hauled to a primary crusher located<br />

near the processing plant. The crushed ore will then be conveyed to the grinding circuit<br />

which will reduce the ore to a finely ground slurry. After being ground, primary ore will<br />

pass to a flotation circuit where the gold-bearing portion of the slurry will be floated off as a<br />

froth or concentrate. The concentrate will then pass to a leaching circuit where cyanide is<br />

added to leach gold from the concentrate. The flotation circuit reduces the amount of ore<br />

required to be cyanide leached and therefore greatly reduces cyanide usage. The ground<br />

oxide ore will be cyanide leached without having to pass through the flotation circuit. The<br />

gold extracted from the cyanide leaching circuit will be recovered and poured as gold bars<br />

(or doré). These gold bars represent the final product of the mine and will be sold to a<br />

refinery for purification.<br />

The finely ground ore residue left after the flotation and leaching processes (tailings) will<br />

be treated to destroy cyanide to prescribed limits and then pumped to one of two tailings<br />

storages. The tailings storages are located about 3.5 km west of the Lake Cowal<br />

shoreline (Figure 2). The tailings storages will be stage constructed throughout the mine<br />

life by raising the height of the embankments in advance of storage requirements. The<br />

bulk of the water from the tailings storages will drain from the surface of the tailings and<br />

collect in the centre of each storage from where it will be reclaimed and recycled within the<br />

processing plant.<br />

The lake isolation system comprises a temporary isolation bund and a permanent lake<br />

protection bund (Figure 2):<br />

• The temporary isolation bund is designed to control water inflow to the pit<br />

development area during construction of the permanent lake protection bund. The<br />

bund is a short term feature and, once the permanent lake protection bund is<br />

constructed and revegetated, it will be reshaped and rehabilitated.<br />

• The lake protection bund will meet specific engineering criteria for compaction so<br />

that it forms a permanent barrier between the lake and the open pit. Revegetation<br />

will occur early in the mine life.<br />

Water Supply Raw water requirements for the mine will be met through a combination of open pit<br />

dewatering, recycling within the processing plant and the tailings water decant and return<br />

system and (where the demand exceeds the available supply from these sources) makeup<br />

water pumped from the external groundwater borefield (Figure 1). The borefield is<br />

located within the Bland palaeochannel and is linked to the mine site via a buried pipeline.<br />

The borefield comprises licensed groundwater production bores.<br />

Access Road Upgrade and<br />

Other Roadworks<br />

Electricity Transmission<br />

Line<br />

Road access to the site will be via an upgraded route from West Wyalong. Within<br />

ML 1535, haul roads and internal roads will be constructed as necessary to provide<br />

transport links between the processing plant, tailings storages, waste rock emplacements<br />

and open pit. In addition, the public road which ran in a north/south direction through<br />

ML 1535 has been closed and replaced by a new public road which has been constructed<br />

in a new travelling stock reserve adjoining the western boundary and part of the northern<br />

and southern boundaries of ML 1535. The location of the new travelling stock reserve is<br />

shown in Figure 2.<br />

Electrical power supply to meet the demands of the Project will be supplied by a new<br />

132 kV line constructed from Temora by Country Energy (Figure 1). A substation is being<br />

constructed to distribute power within ML 1535.<br />

Rehabilitation The rehabilitation philosophy for the mine site is to create stable rehabilitated landforms<br />

which increase areas of endemic vegetation in ML 1535 and the status of lake-land<br />

habitats.<br />

HAL-02-07/1/25/CMP-01-Q.DOC 6 BARRICK