TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

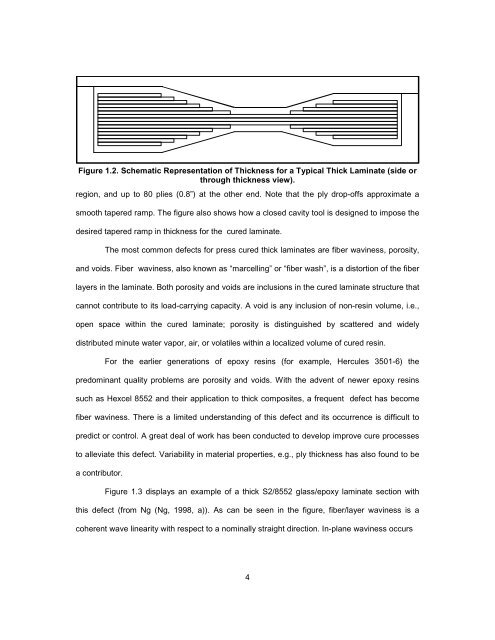

Figure 1.2. Schematic Representation of Thickness for a Typical Thick Laminate (side or<br />

through thickness view).<br />

region, and up to 80 plies (0.8”) at the other end. Note that the ply drop-offs approximate a<br />

smooth tapered ramp. The figure also shows how a closed cavity tool is designed to impose the<br />

desired tapered ramp in thickness for the cured laminate.<br />

The most common defects for press cured thick laminates are fiber waviness, porosity,<br />

and voids. Fiber waviness, also known as “marcelling” or “fiber wash”, is a distortion of the fiber<br />

layers in the laminate. Both porosity and voids are inclusions in the cured laminate structure that<br />

cannot contribute to its load-carrying capacity. A void is any inclusion of non-resin volume, i.e.,<br />

open space within the cured laminate; porosity is distinguished <strong>by</strong> scattered and widely<br />

distributed minute water vapor, air, or volatiles within a localized volume of cured resin.<br />

For the earlier generations of epoxy resins (for example, Hercules 3501-6) the<br />

predominant quality problems are porosity and voids. With the advent of newer epoxy resins<br />

such as Hexcel 8552 and their application to thick composites, a frequent defect has become<br />

fiber waviness. There is a limited understanding of this defect and its occurrence is difficult to<br />

predict or control. A great deal of work has been conducted to develop improve cure processes<br />

to alleviate this defect. Variability in material properties, e.g., ply thickness has also found to be<br />

a contributor.<br />

Figure 1.3 displays an example of a thick S2/8552 glass/epoxy laminate section with<br />

this defect (from Ng (Ng, 1998, a)). As can be seen in the figure, fiber/layer waviness is a<br />

coherent wave linearity with respect to a nominally straight direction. In-plane waviness occurs<br />

4