TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Flexbeam (z) Height and Tool Lid Position (m)<br />

0.09<br />

0.085<br />

0.08<br />

0.075<br />

0.07<br />

0.065<br />

0.06<br />

0.055<br />

0.05<br />

Uncured Laminate Top<br />

Lid<br />

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0<br />

Position along Flexbeam Length (m)<br />

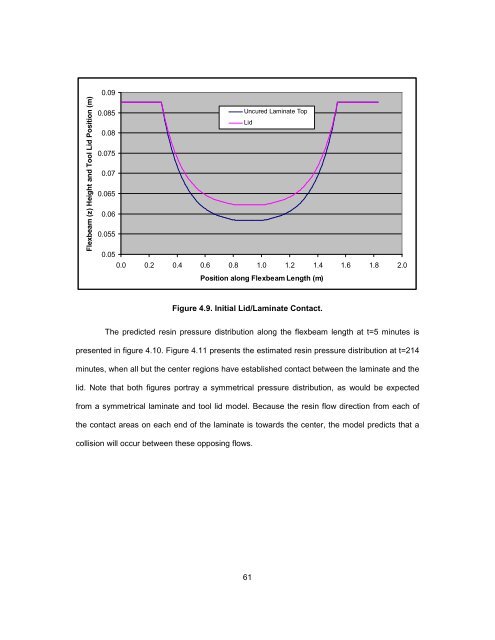

Figure 4.9. Initial Lid/Laminate Contact.<br />

The predicted resin pressure distribution along the flexbeam length at t=5 minutes is<br />

presented in figure 4.10. Figure 4.11 presents the estimated resin pressure distribution at t=214<br />

minutes, when all but the center regions have established contact between the laminate and the<br />

lid. Note that both figures portray a symmetrical pressure distribution, as would be expected<br />

from a symmetrical laminate and tool lid model. Because the resin flow direction from each of<br />

the contact areas on each end of the laminate is towards the center, the model predicts that a<br />

collision will occur between these opposing flows.<br />

61