TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

For any timestep the resin pressure is used to calculate the resin flow velocity from<br />

Darcy’s Law, and the resin flow volume rate based on the current cross-sectional area. At the<br />

beginning of the next timestep, the new resin volume is calculated <strong>by</strong> subtracting the resin flow<br />

volume rate * delta time from the previous volume. The last resin pressure level is not<br />

maintained or used for the next timestep when Pappl is monotonically increasing. Each timestep<br />

is then treated discretely with respect to resin pressure: the new Pappl value is applied to the split<br />

of resin pressure vs. ESS based on Vf. New resin pressure value is not added to the previous<br />

one. However, when a constant Pappl (mode 2) or a constant Z position (mode 3) is used, a resin<br />

bleed mechanism utilizing the pressure film approach is used.<br />

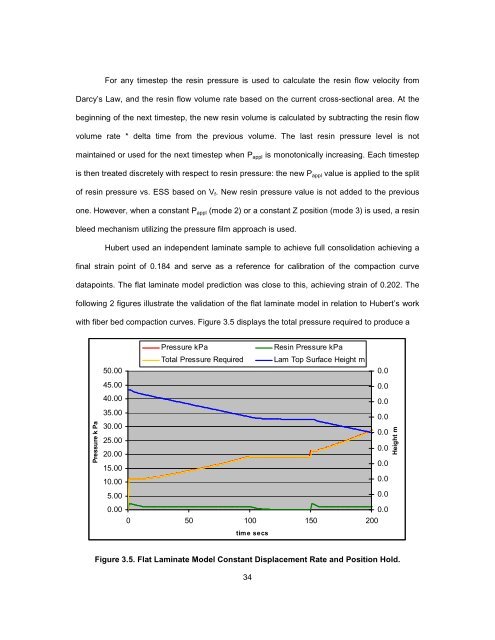

Hubert used an independent laminate sample to achieve full consolidation achieving a<br />

final strain point of 0.184 and serve as a reference for calibration of the compaction curve<br />

datapoints. The flat laminate model prediction was close to this, achieving strain of 0.202. The<br />

following 2 figures illustrate the validation of the flat laminate model in relation to Hubert’s work<br />

with fiber bed compaction curves. Figure 3.5 displays the total pressure required to produce a<br />

Pressure k Pa<br />

50.00<br />

45.00<br />

40.00<br />

35.00<br />

30.00<br />

25.00<br />

20.00<br />

15.00<br />

10.00<br />

5.00<br />

0.00<br />

Pressure kPa Resin Pressure kPa<br />

Total Pressure Required Lam Top Surface Height m<br />

0 50 100 150 200<br />

time secs<br />

Figure 3.5. Flat Laminate Model Constant Displacement Rate and Position Hold.<br />

34<br />

0.0<br />

0.0<br />

0.0<br />

0.0<br />

0.0<br />

0.0<br />

0.0<br />

0.0<br />

0.0<br />

0.0<br />

Height m