TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Resin Pressure (Pa)<br />

1.2E+06<br />

1.0E+06<br />

8.0E+05<br />

6.0E+05<br />

4.0E+05<br />

2.0E+05<br />

0.0E+00<br />

1 3 5 7 9 11 13 15 17 19 21 23 25<br />

Position along Flexbeam Length<br />

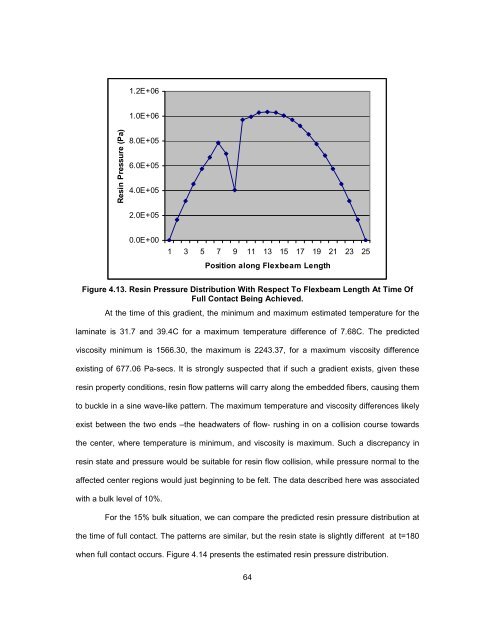

Figure 4.13. Resin Pressure Distribution With Respect To Flexbeam Length At Time Of<br />

Full Contact Being Achieved.<br />

At the time of this gradient, the minimum and maximum estimated temperature for the<br />

laminate is 31.7 and 39.4C for a maximum temperature difference of 7.68C. The predicted<br />

viscosity minimum is 1566.30, the maximum is 2243.37, for a maximum viscosity difference<br />

existing of 677.06 Pa-secs. It is strongly suspected that if such a gradient exists, given these<br />

resin property conditions, resin flow patterns will carry along the embedded fibers, causing them<br />

to buckle in a sine wave-like pattern. The maximum temperature and viscosity differences likely<br />

exist between the two ends –the headwaters of flow- rushing in on a collision course towards<br />

the center, where temperature is minimum, and viscosity is maximum. Such a discrepancy in<br />

resin state and pressure would be suitable for resin flow collision, while pressure normal to the<br />

affected center regions would just beginning to be felt. The data described here was associated<br />

with a bulk level of 10%.<br />

For the 15% bulk situation, we can compare the predicted resin pressure distribution at<br />

the time of full contact. The patterns are similar, but the resin state is slightly different at t=180<br />

when full contact occurs. Figure 4.14 presents the estimated resin pressure distribution.<br />

64