TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

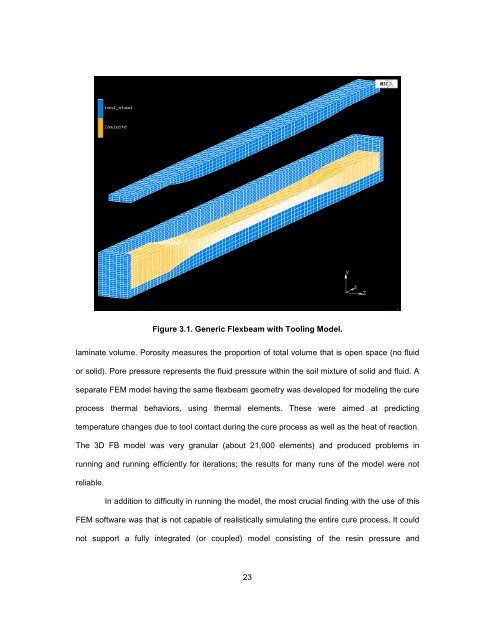

Figure 3.1. Generic Flexbeam with Tooling Model.<br />

laminate volume. Porosity measures the proportion of total volume that is open space (no fluid<br />

or solid). Pore pressure represents the fluid pressure within the soil mixture of solid and fluid. A<br />

separate FEM model having the same flexbeam geometry was developed for modeling the cure<br />

process thermal behaviors, using thermal elements. These were aimed at predicting<br />

temperature changes due to tool contact during the cure process as well as the heat of reaction.<br />

The 3D FB model was very granular (about 21,000 elements) and produced problems in<br />

running and running efficiently for iterations; the results for many runs of the model were not<br />

reliable.<br />

In addition to difficulty in running the model, the most crucial finding with the use of this<br />

FEM software was that is not capable of realistically simulating the entire cure process. It could<br />

not support a fully integrated (or coupled) model consisting of the resin pressure and<br />

23