TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

TOOLED THICK COMPOSITES by ARVEN H. SAUNDERS III ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Te m pe ra ture (°F) / Pre ssure<br />

(psi)<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

C los ure<br />

B o n d P ress C u re C y cle<br />

P laten<br />

Tem ps<br />

P art<br />

Tem ps<br />

P res s<br />

P res s ure<br />

0 60 120 180 240 300 360 420 480<br />

T im e (m in u te s)<br />

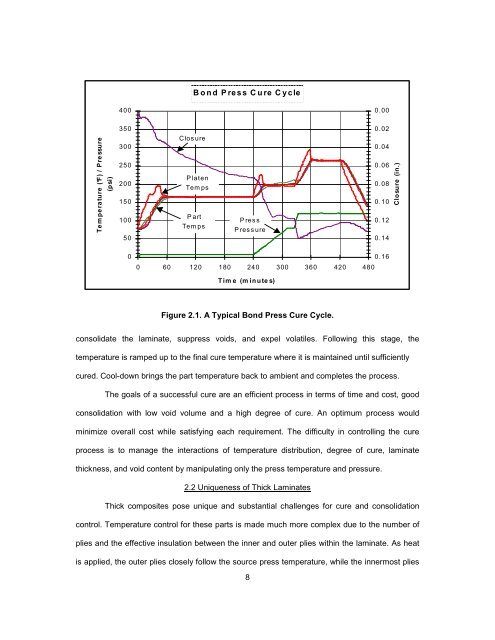

Figure 2.1. A Typical Bond Press Cure Cycle.<br />

consolidate the laminate, suppress voids, and expel volatiles. Following this stage, the<br />

temperature is ramped up to the final cure temperature where it is maintained until sufficiently<br />

cured. Cool-down brings the part temperature back to ambient and completes the process.<br />

The goals of a successful cure are an efficient process in terms of time and cost, good<br />

consolidation with low void volume and a high degree of cure. An optimum process would<br />

minimize overall cost while satisfying each requirement. The difficulty in controlling the cure<br />

process is to manage the interactions of temperature distribution, degree of cure, laminate<br />

thickness, and void content <strong>by</strong> manipulating only the press temperature and pressure.<br />

2.2 Uniqueness of Thick Laminates<br />

Thick composites pose unique and substantial challenges for cure and consolidation<br />

control. Temperature control for these parts is made much more complex due to the number of<br />

plies and the effective insulation between the inner and outer plies within the laminate. As heat<br />

is applied, the outer plies closely follow the source press temperature, while the innermost plies<br />

8<br />

0.00<br />

0.02<br />

0.04<br />

0.06<br />

0.08<br />

0.10<br />

0.12<br />

0.14<br />

0.16<br />

Closure (in.)